Passivation method and device for sliced battery, sliced battery and photovoltaic module

A slicing and battery technology, applied in photovoltaic power generation, electrical components, circuits, etc., can solve problems such as limiting the progress of photovoltaic module development, photovoltaic module power loss, and slicing battery efficiency loss, etc., to improve photoelectric efficiency, good photoelectric efficiency, The effect of good photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

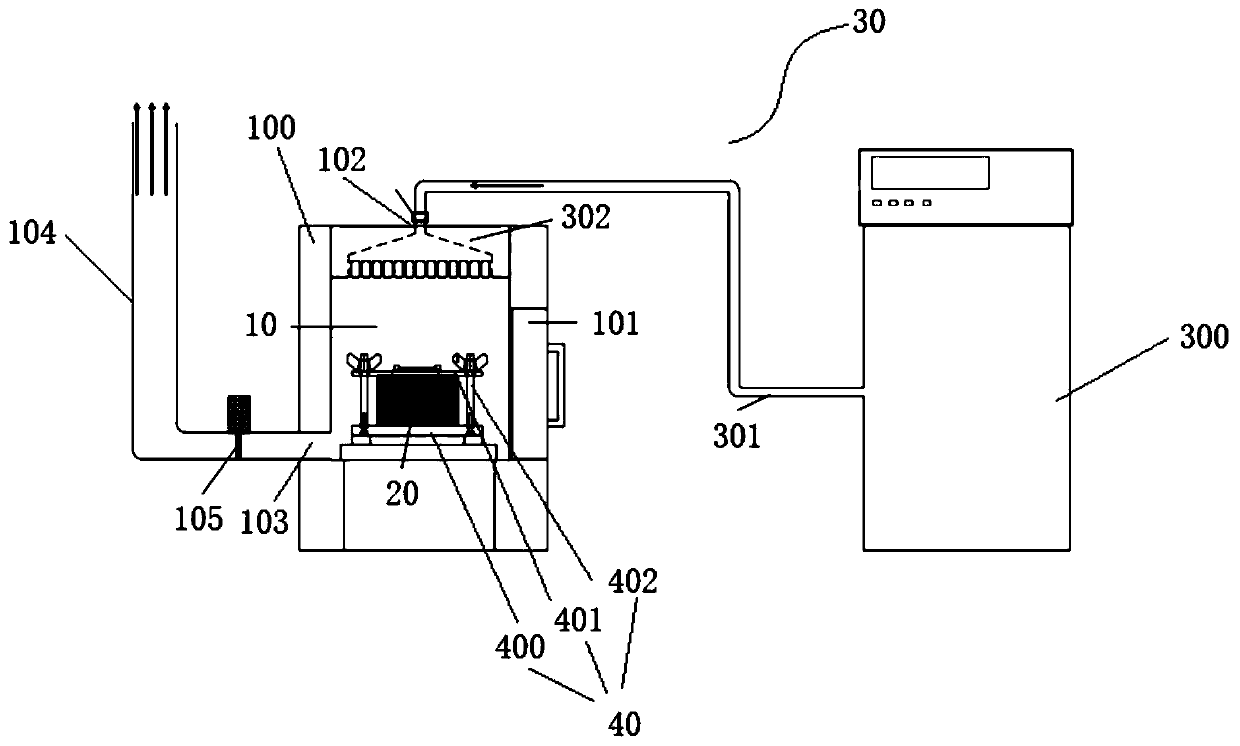

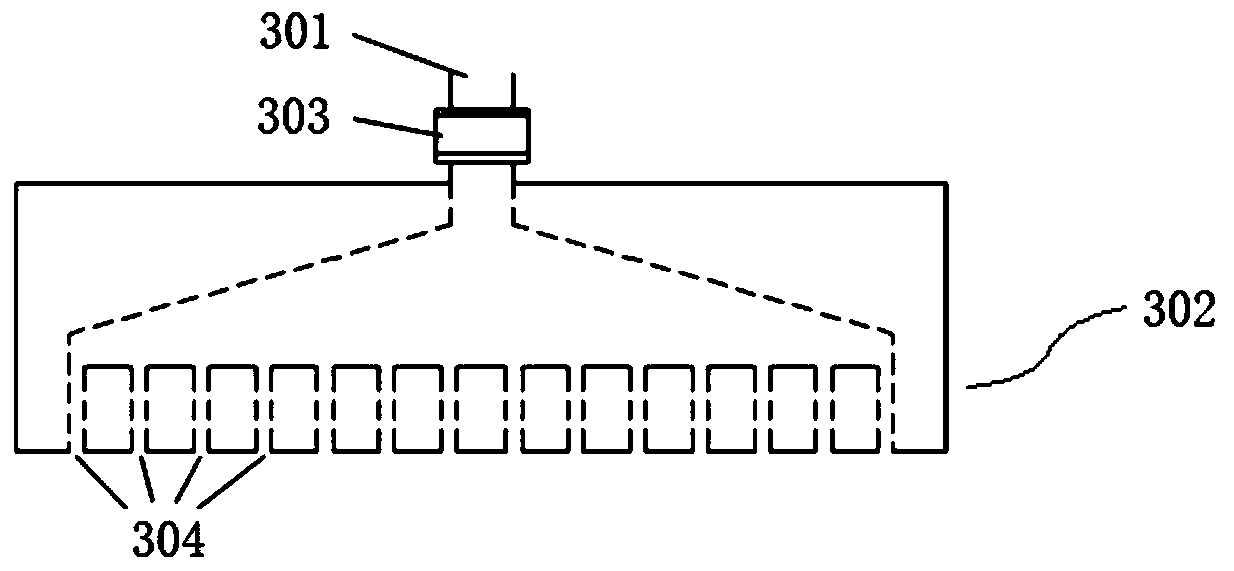

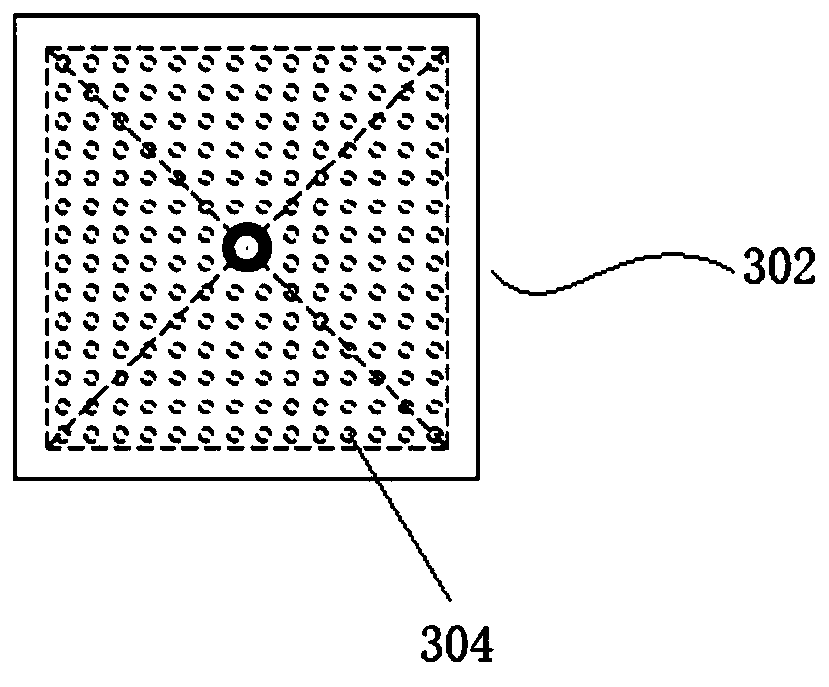

[0074] S100, take 5 busbar half-cut patterned HIT cells and stack them sequentially between the carrier plate 400 and the cover plate 401 (for details, refer tofigure 1 ), placed in the box body 100, close the box door 101, close the pneumatic valve 105 on the exhaust pipeline 104, set the parameters of the ozone generator 300, and open the ozone generator 300 so that the output volume concentration is 150 Ozone at a rate of 10,000 is sprayed into the box body 100 for 90 seconds at a flow rate of 1 liter / min through the pipeline 301, the adapter 303 and the nozzle 302;

[0075] S101. Turn off the ozone generator 300, open the pneumatic valve 105, and open the box door 101 after the ozone in the box body 100 is emptied.

[0076] The obtained sliced battery is denoted as A1.

Embodiment 2

[0078] S100. Stack and clamp 5 busbar half-cut PERC cells sequentially between the carrier plate 400 and the cover plate 401 (for details, refer to figure 1 ), placed in the box body 100, close the box door 101, close the pneumatic valve 105 on the exhaust pipeline 104, set the parameters of the ozone generator 300, and open the ozone generator 300 so that the output volume concentration is 150 Ozone at a rate of 10,000 is sprayed into the box body 100 for 90 seconds at a flow rate of 1 liter / min through the pipeline 301, the adapter 303 and the nozzle 302;

[0079] S101. Turn off the ozone generator 300, open the pneumatic valve 105, and open the box door 101 after the ozone in the box body 100 is emptied.

[0080] The obtained sliced battery is denoted as A2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com