Optical film

A technology of optical film and optical structure, which is applied in the field of optical film, can solve the problems of simplification, compounding, general light-gathering and brightening effect, and overall film thickness, etc., so as to reduce product cost and improve optical gain , reducing the effect of absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

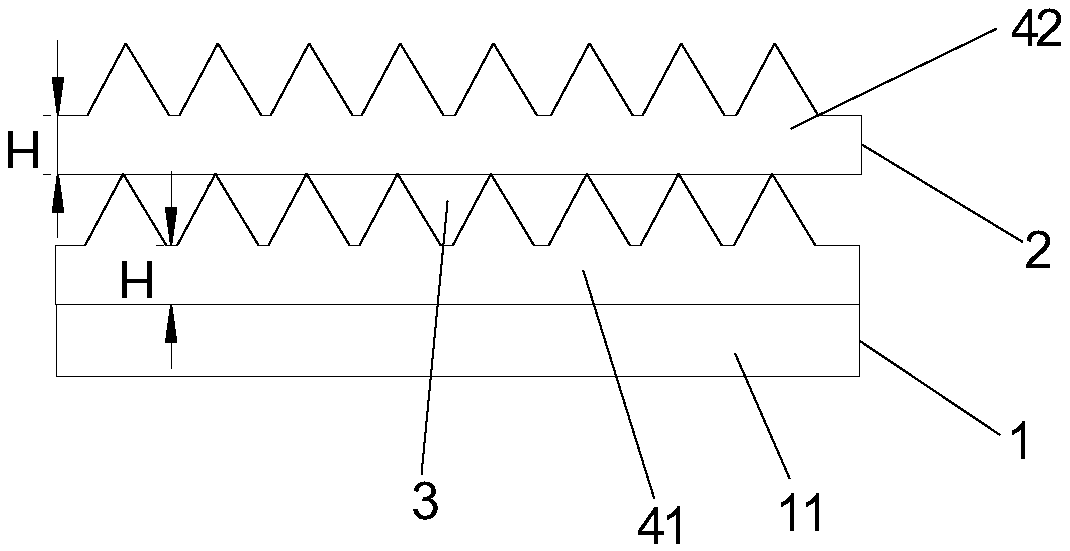

[0024] See attached figure 1 Shown, a kind of optical film among the present embodiment comprises the first optical film structural layer 1 and the second optical film structural layer 2 that are fixed mutually, and the second optical film structural layer 2 has self-adhesiveness, by thermal curing (stamping) , hot stamping), UV curing, ultraviolet treatment, dual curing (such as thermosetting-photo-curing, photo-curing-thermosetting) and other methods make the first optical film structure layer 1 and the second optical film structure layer 2 fixed to each other, and can also Secured with adhesive. The first optical film structure layer has a support layer 11, and the second optical film structure layer 2 does not contain a support layer. An air structure 3 is left between the first optical film structure layer 1 and the second optical film structure layer 2 . Because the air structure 3 is arranged between the first optical film structure layer 1 and the second optical film...

Embodiment 2

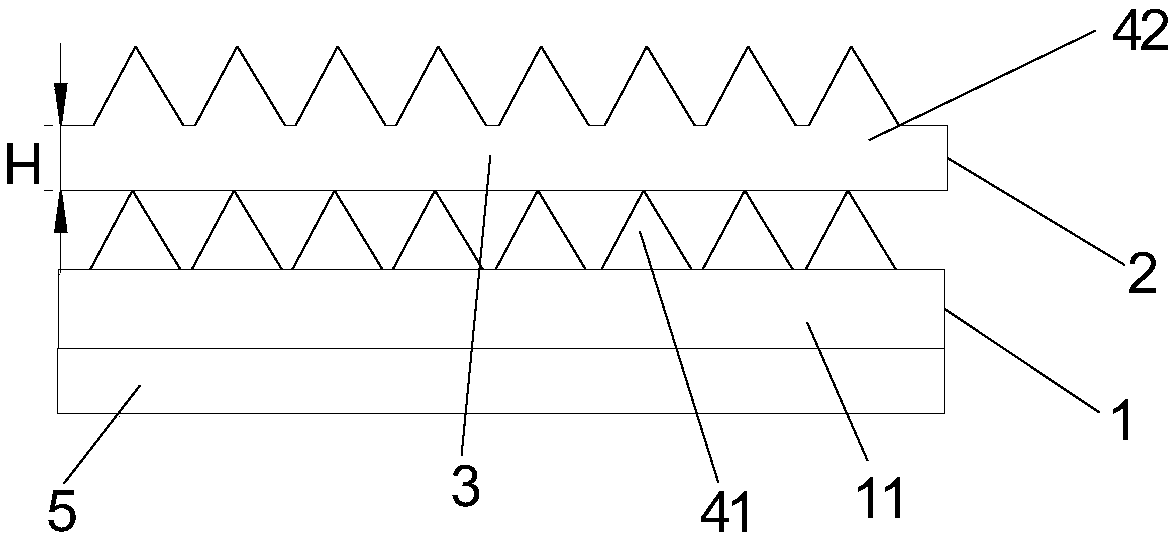

[0028] See attached figure 2 Shown, a kind of optical film among the present embodiment comprises the first optical film structural layer 1 and the second optical film structural layer 2 that are fixed mutually, and the second optical film structural layer 2 has self-adhesiveness, by thermal curing (stamping) , hot stamping), UV curing, ultraviolet treatment, dual curing (such as thermosetting-photo-curing, photo-curing-thermosetting) and other methods make the first optical film structure layer 1 and the second optical film structure layer 2 fixed to each other, and can also Secured with adhesive. The first optical film structure layer has a support layer 11 , and the second optical film structure layer does not contain a support layer 11 . An air structure 3 is left between the first optical film structure layer 1 and the second optical film structure layer 2 . However, because the air structure 3 is arranged between the first optical film structure layer 1 and the second...

Embodiment 3

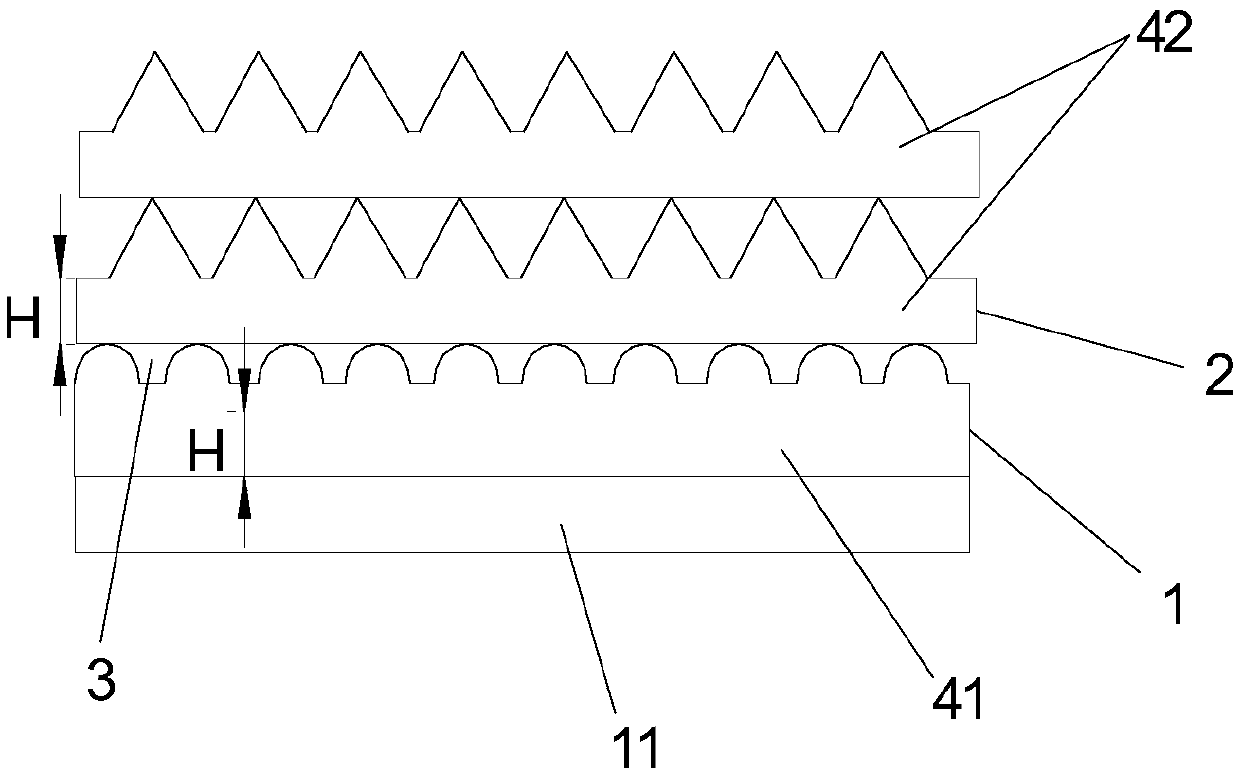

[0033] See attached image 3 As shown, a kind of optical film in the present embodiment comprises the first optical film structural layer 1 and the second optical film structural layer 2 that are bonded to each other, and the second optical film structural layer 2 has self-adhesiveness, and is cured by heat (pressing) Stamping, hot stamping), UV curing, ultraviolet treatment, double curing (such as thermosetting-light curing, light curing-thermosetting) and other methods make the first optical film structure layer 1 and the second optical film structure layer 2 fixed to each other, and also Can be fixed with adhesive. The first optical film structure layer has a support layer 11 , and the second optical film structure layer does not contain a support layer 11 . An air structure 3 is left between the first optical film structure layer 1 and the second optical film structure layer 2 . But because the air structure 3 is arranged between the first optical film structure layer 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com