Vortex street cross-correlation flowmeter based on micro transient pressure sensors

A transient pressure and sensor technology, applied in the direction of volume/mass flow, measurement flow/mass flow, liquid/fluid solid measurement, etc. generated by mechanical effects, it can solve the problem of poor resistance to vibration interference signals, distortion of vortex flow measurement, Reduce practical value and other problems, to achieve the effect of ensuring accuracy and cross-correlation calculation accuracy, reducing the lower limit of measurement, and improving the range ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

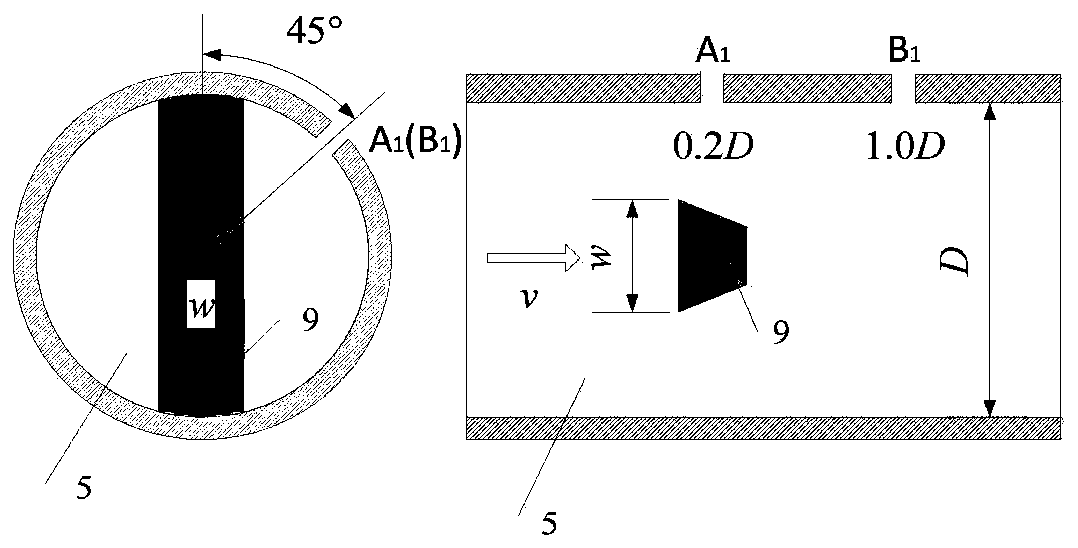

[0017] The invention provides a vortex flow measuring device suitable for small diameter pipelines. The device can meet the full frequency range measurement in the high-frequency and high-speed gas-phase vortex flow field, and expand the range of the vortex flow characteristic curve. Specifically, the present invention is realized by the following devices and technical methods:

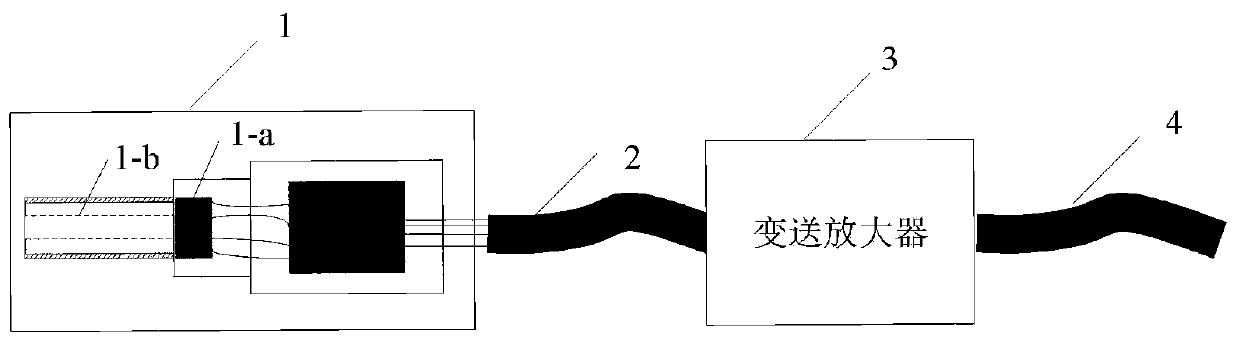

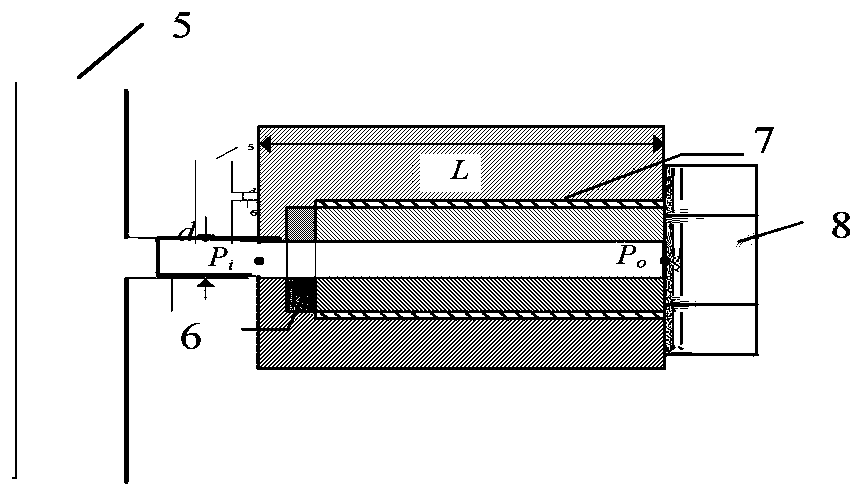

[0018] A small-diameter wide-range vortex cross-correlation flowmeter based on a miniature transient pressure sensor, which is suitable for flow measurement of small-diameter pipelines under high-speed flow field conditions. The miniature transient sensor is used as a measuring element to measure the velocity based on cross-correlation theory . The transient pressure sensor mainly includes a probe 1, a front-end lead wire 2, a transmission amplifier 3, and a rear-end lead wire 4. The probe 1 includes a sensitive element 1-a and a pressure introduction tube 1-b, the sensitive element 1-a is located a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com