Microporous structure foam light soil and preparation method thereof

A technology of foam light soil and microporous structure, which is applied in the field of foam light soil, can solve the problems of uneven performance and quality of foam light soil, increase of density and quality of foam light soil, and achieve good product performance , Enhanced reinforcing effect, uniform pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The 300kg class microporous structure foam lightweight soil is made of the following raw materials: 250kg of PO425 cement, 0.06kg of foaming agent, 20kg of 1000 mesh silica fume, and 175kg of water.

[0045] The preparation method specifically comprises the following steps:

[0046] (1) take each raw material by the quality of above-mentioned microporous structure foam light soil;

[0047] (2) fully stirring and mixing PO425 cement and water to obtain a slurry;

[0048] (3) The foaming agent is mixed with water at a mass ratio of 1:60 (water 3.6kg) for immediate dilution, and added to a foaming machine for foaming to obtain a foamed foam; in the foaming process, the foamed foam The density is stable at 42±2kg / m 3 , the foam settlement distance is not greater than 3mm, the bleeding volume is not greater than 25mL, and the foaming air pressure is controlled at 0.62±0.01MPa;

[0049] (4) Stir and mix the slurry obtained in step (2), the foaming foam obtained in step (3) a...

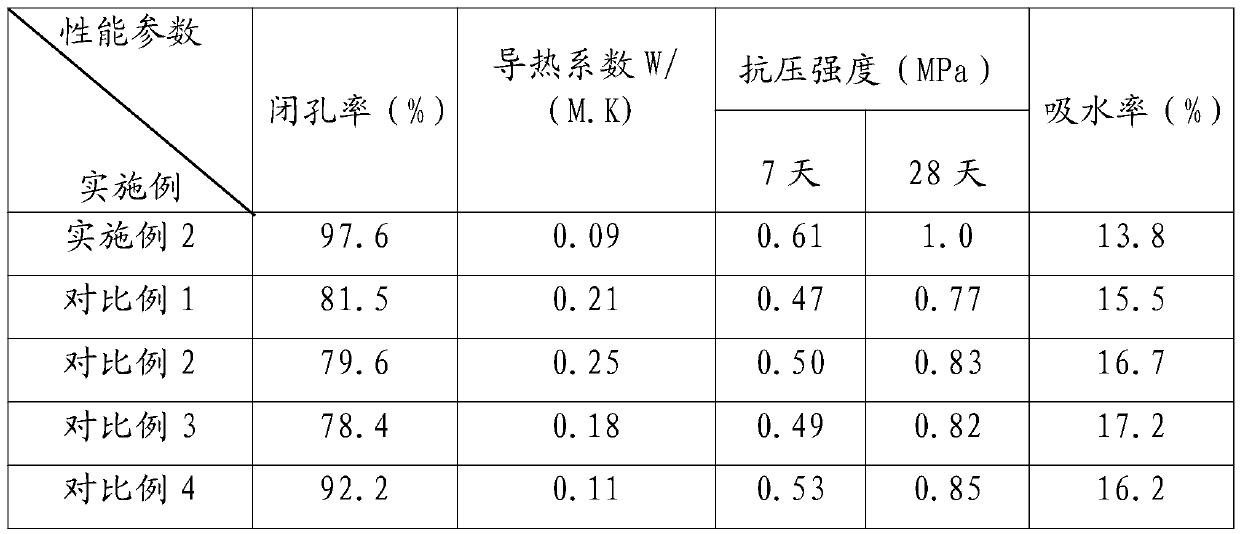

Embodiment 2

[0052] A road and bridge project uses 400kg-class microporous structure foam light soil, which is made of the following raw materials: PO425 cement 310kg, foaming agent 0.5kg, 1500 mesh micro-silica fume 25kg, magnesium chloride 18kg, water 220kg.

[0053] The preparation method specifically comprises the following steps:

[0054] (1) take each raw material by the quality of above-mentioned microporous structure foam light soil;

[0055] (2) Using Huatai HT-18 intelligent large-scale foam concrete production equipment, fully mix PO425 cement and water to obtain slurry;

[0056] (3) Foaming agent and water are mixed with the mass ratio of 1:50 (water 25kg) and carry out instant dilution, and add in the foaming machine and foam, obtain foaming foam; In the foaming process, the foam density of foaming Stable at 48±2kg / m 3 , the foam settlement distance is not greater than 3mm, the bleeding volume is not greater than 25mL, and the foaming air pressure is controlled at 0.7±0.01MP...

Embodiment 3

[0060] The 500 kg-level microporous structure foam light soil is made of the following raw materials: 380 kg of 600-mesh hydraulic gelling material micropowder, 1 kg of foaming agent, 40 kg of 1000-mesh micro-silica fume, 26 kg of anhydrous sodium sulfate, and 270 kg of water;

[0061] Among them, the fine powder of hydraulic cementitious material is obtained by mixing and grinding PO425 cement, fly ash, and copper tailings powder at a mass ratio of 3:1:2 to 600 mesh.

[0062] The preparation method specifically comprises the following steps:

[0063] (1) take each raw material by the quality of above-mentioned microporous structure foam light soil;

[0064] (2) Fully stirring and mixing the micropowder of the hydraulic gelling material and water to obtain a slurry;

[0065] (3) Foaming agent and water are mixed with the mass ratio of 1:80 (water 80kg) and carry out instant dilution, and add in foaming machine and foam, obtain foaming foam; During foaming, the foam density of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com