A kind of processing method of polyester filament

A polyester filament and processing method technology, applied in the textile field, can solve problems such as prone to stuffiness, affect the wearing experience, and poor air permeability, and achieve the goals of improving wearing comfort, enhancing air permeability, and enhancing air permeability and comfort Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

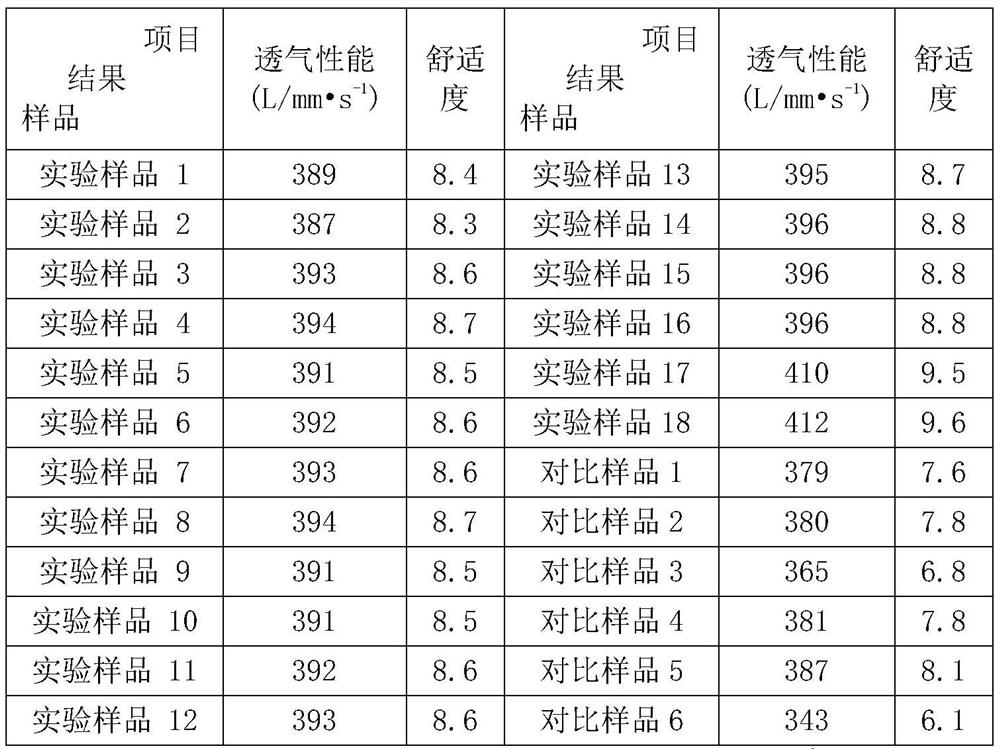

Examples

Embodiment 1

[0046] A kind of processing method of polyester filament, the concrete component that comprises and weight are as shown in table 2, make by following steps:

[0047] S1: chitosan, graphene, auxiliary agent and deionized water are mixed and stirred, and the stirring speed is 700r / min, and after stirring, the post-treatment solution is obtained;

[0048] S2: mix and stir polyester chips, blue carbon powder, zeolite powder, fly ash, polyvinylpyrrolidone and accelerator, and the stirring speed is 1000r / min, and the mixture is obtained after stirring; the mixture is dried, and the drying temperature is 150 ° C , the drying time is 35min to obtain the dried mixture;

[0049] S3: carry out melt extrusion of the mixture after drying, the temperature of melt extrusion is 280 ℃, the screw speed is 100r / min, after filtering through the filter screen of 20 microns, obtains the extruded polyester thread;

[0050] S4: The extruded polyester filaments are distributed and spun at a spinning ...

Embodiment 2

[0051] Embodiment 2: a kind of processing method of polyester filament, the difference with embodiment 1 is that concrete component and weight are different, and the concrete component and weight that comprise are as shown in table 2.

Embodiment 3-4

[0052] Embodiment 3-4: a kind of processing method of polyester filament, the difference with embodiment 1 is that the component of accelerator is different, and the specific component and weight included are as shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com