Preparation method of porous fiber-based aerogel adsorbent

A porous fiber and airgel technology, applied in the field of materials, can solve the problems such as the inability to realize the recycling and reuse of waste resources, and achieve the effect of enhancing the richness of pores, efficient adsorption performance, and increasing the richness and strength of pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

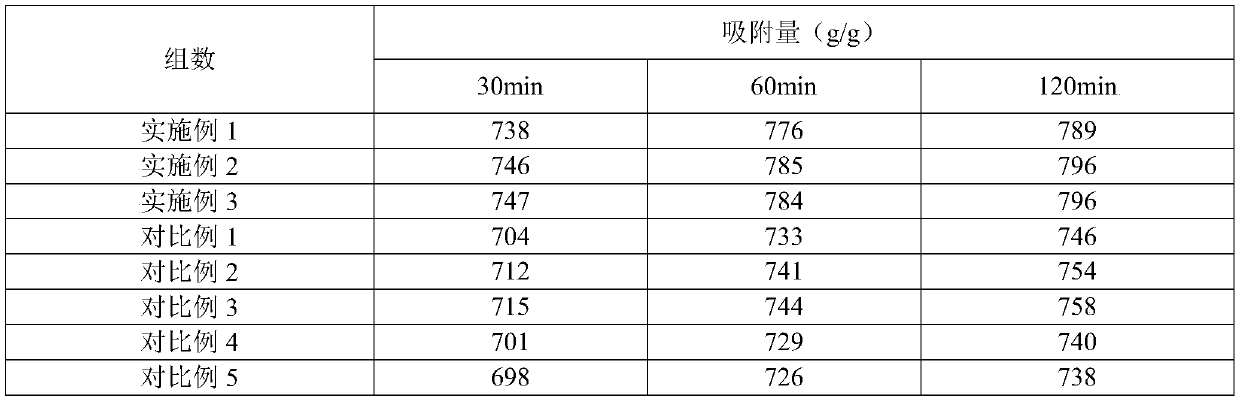

Examples

Embodiment 1

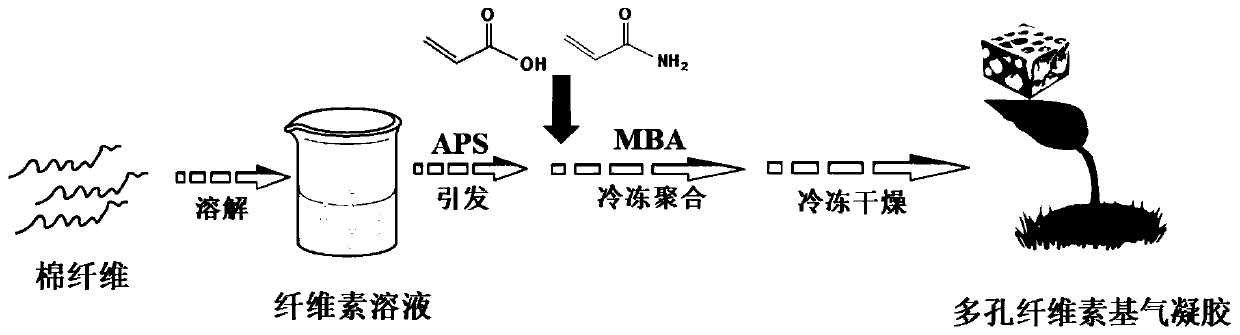

[0031] A preparation method of porous fiber-based airgel adsorbent, comprising the following steps:

[0032] (1) Disperse the cellulose in the cellulose dissolving solution and freeze at -15°C for 2 hours to obtain a cellulose solution; the mass ratio of the cellulose to the cellulose dissolving solution is 1:33, and the cellulose dissolving solution It is a mixed solution of 7wt% NaOH solution and 12wt% urea solution;

[0033] (2) Add APS to the cellulose solution to initiate free radicals, stir for 30 minutes, then add acrylic acid, acrylamide and N,N-methylenebisacrylamide with a neutralization degree of 60%, and stir at 25°C and 300rpm Polymerize for 12 hours to obtain a gel-like polymer; the mass ratio of the APS-induced free radicals, acrylic acid, acrylamide and N,N-methylenebisacrylamide is 1:100:20:0.6, and the cellulose and APS-induced The mass ratio of free radicals is 1:0.1;

[0034] (3) The gel polymer was repeatedly washed with alcohol and water, and then freez...

Embodiment 2

[0036] A preparation method of porous fiber-based airgel adsorbent, comprising the following steps:

[0037](1) Disperse the cellulose in the cellulose dissolving solution and freeze at -15°C for 2 hours to obtain a cellulose solution; the mass ratio of the cellulose to the cellulose dissolving solution is 1:33, and the cellulose dissolving solution It is a mixed solution of 7wt% NaOH solution and 12wt% urea solution;

[0038] (2) Add APS to the cellulose solution to initiate free radicals, stir for 30 minutes, add modified activated carbon, stir for 5 minutes, add acrylic acid, acrylamide and N,N-methylenebisacrylamide with a neutralization degree of 60% , stirred and polymerized at 25°C and 300rpm for 12h to obtain a gel-like polymer; the mass ratio of the APS-initiated free radical, acrylic acid, acrylamide, modified activated carbon and N,N-methylenebisacrylamide is 1 :100:20:0.9:0.6, the mass ratio of cellulose and APS to initiate free radicals is 1:0.1;

[0039] (3) Th...

Embodiment 3

[0042] A preparation method of porous fiber-based airgel adsorbent, comprising the following steps:

[0043] (1) Disperse the cellulose in the cellulose dissolving solution and freeze at -10°C for 3 hours to obtain the cellulose solution; the mass ratio of the cellulose to the cellulose dissolving solution is 1:35, and the cellulose dissolving solution It is a mixed solution of 9wt% NaOH solution and 10wt% urea solution;

[0044] (2) Add APS to the cellulose solution to initiate free radicals, stir for 40 minutes, add modified activated carbon, stir for 2 minutes, add acrylic acid, acrylamide and N,N-methylenebisacrylic acid with a neutralization degree of 40% Amide was stirred and polymerized at 30°C and 400rpm for 9h to obtain a gel-like polymer; the mass ratio of the APS-induced free radicals, acrylic acid, acrylamide, modified activated carbon, and N,N-methylenebisacrylamide was 1:80:30:0.6:1, the mass ratio of cellulose and APS to initiate free radicals is 1:0.15;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com