Method and device for cleaning multi-pollutant flue gas

A technology for cleaning treatment and pollutants, applied in gas treatment, water/sewage multi-stage treatment, neutralized water/sewage treatment, etc., which can solve the problems that limit the popularization and application of activated carbon flue gas control technology, the exhaust gas does not meet the standard, and the use time is short, etc. problems, to achieve the effect of clean recycling, lower investment costs, and reduced usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

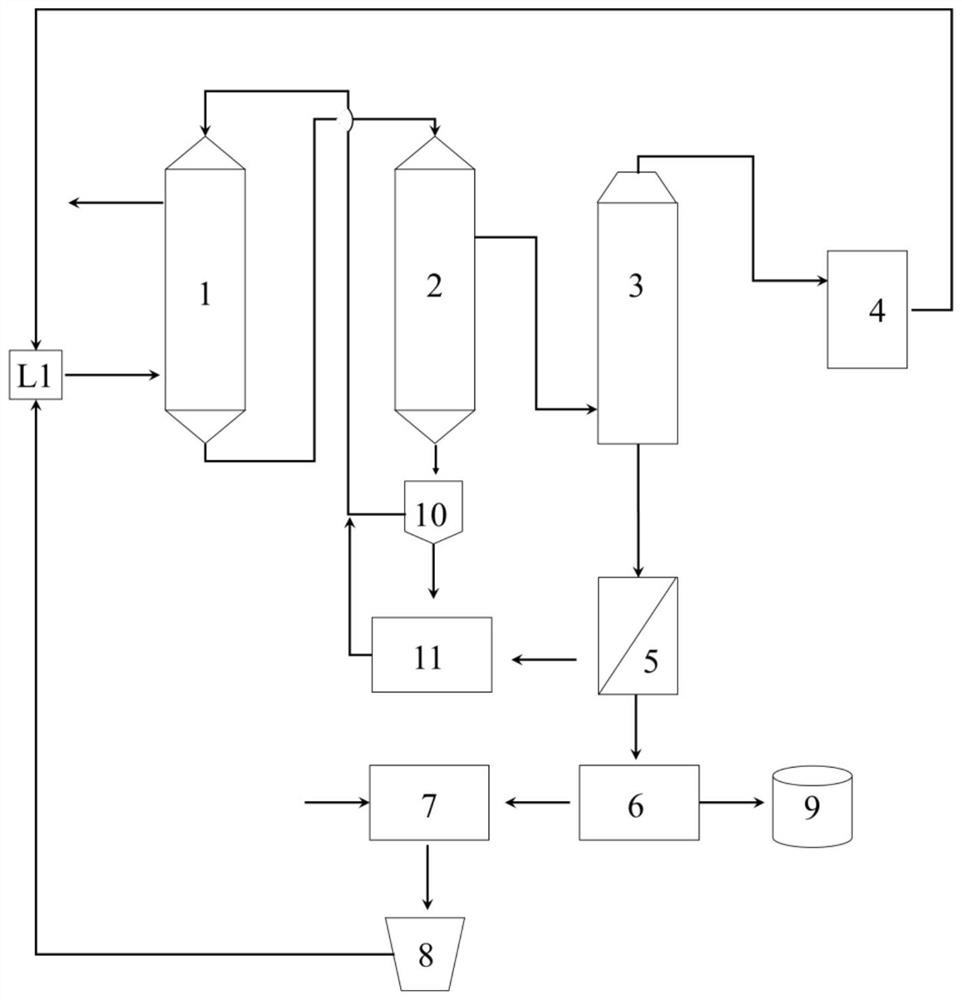

[0115] like image 3 As shown, a multi-pollutant flue gas synergistic governance and wastewater zero emissions or means for the method described in the first embodiment, including flue gas delivery pipes L1, flue gas adsorption device 1, activated carbon hot The regeneration device 2, the wet detergent device 3, the sulfur resource device 4, the acidic filtration device 5, flocculation precipitation device 6. The multi-pollutant flue gas is delivered to the flue gas adsorption device 1 through the flue gas delivery pipe L1. The activated carbon outlet of the flue gas adsorption device 1 is attached to the active carbon thermal regeneration device 2 through the conveying device. The SRG gas outlet of the activated carbon thermal regeneration apparatus 2 is connected to the wet detergent device 3 through the conduit. The high sulfur gase of the wet detergent device 3 is coupled to the sulfur resource device 4. The wastewater outlet of the wet detergent device 3 is connected to the ac...

Embodiment 2

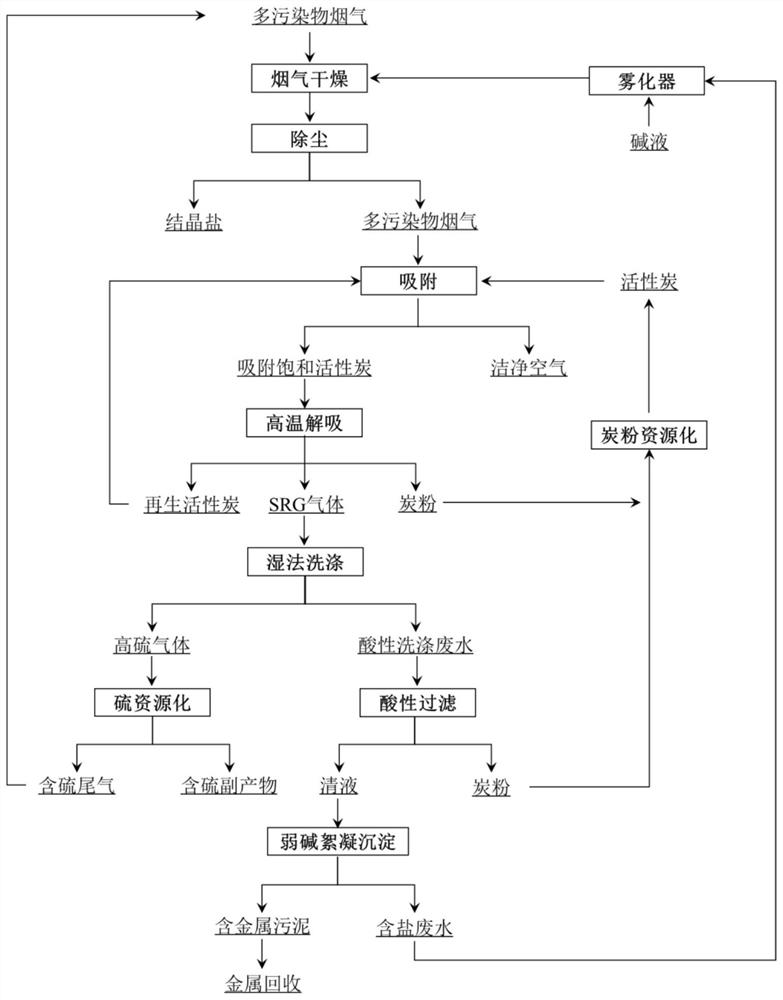

[0117] Example 1 was repeated, but the apparatus further includes an atomizer 7, a dust collector 8, a metal recovery device 9. The liquid outlet of the flocculation precipitation device 6 is coupled to the atomizer 7. The outlet of the atomizer 7 is connected to the dust collector 8. The dust collector 8 is disposed on the flue gas delivery conduit L1. The atomizer 7 is provided with an alkali inlet. The solid outlet of the flocculation precipitation device 6 is coupled to the metal recovery device 9. The apparatus also includes a screening device 10, a carbon powder resource device 11. The activated carbon exit of the activated carbon thermal regeneration apparatus 2 is coupled to the screening device 10. The large particulate activated carbon outlet of the screening device 10 is coupled to the flue gas adsorption device 1. The small particulate activated carbon outlet of the sieve device 10, the solid outlet of the acidic filtration device 5 is coupled to the carbon powder reso...

Embodiment 3

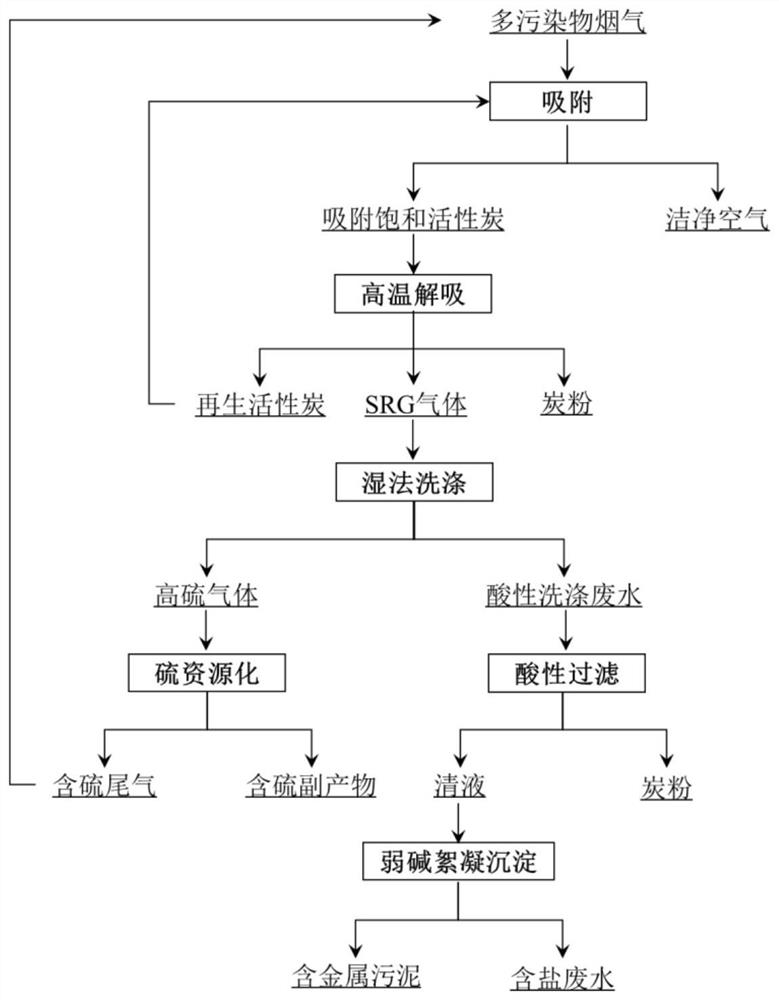

[0119] like figure 1 As shown, a multi-pollutant flue gas cleaning treatment method, the method includes the following steps:

[0120] 1) Adsorption of multi-pollutant flue gas: Transfer multi-pollutant flue gas to the flue gas adsorption device 1 through the flue gas delivery pipe L1, and the flue gas adsorption device 1 has activated carbon, and the multi-pollutant flue gas uses activated carbon with eruption adsorption. Treatment, adsorb saturated activated carbon;

[0121] 2) Thermal regeneration of activated carbon: transports adsorption saturated activated carbon to the activated carbon thermal regeneration apparatus 2. The adsorption saturated activated carbon is heated to 400 ° C for heat and regeneration;

[0122] 3) Treatment of the SRG gas: The SRG gas produced by the activated carbon thermal regeneration is wetly washed by the wet detergent device 3, and the solution used by the wet washing is dilute, the pH is 5; the volume flow ratio of SRG gas and dilute sulfuric ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com