Application of a Photoelectric Detection Material in Ultraviolet Light Detection

A photoelectric detection and ultraviolet light technology, applied in the field of photoelectric sensing, can solve the problems of large volume, low sensitivity, poor pertinence, etc., and achieve the effects of small device size, process compatibility and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Transfer 15 nm thick MoS on heavily doped silicon or silicon dioxide substrate by dry transfer method 2 flakes;

[0030] (2) Use MODELWA-650MZ-23NPP homogenizer with semiconductor material MoS 2 Spin-coat PMMA950 on the substrate as an electron beam photoresist, use an FEI Inspect F50 scanning electron microscope to perform electron beam lithography to expose both ends of the material, and use a Techno metal evaporation instrument to deposit titanium / gold on both sides of the exposed material (10nm / 35nm) as the test electrode of the material;

[0031] (3) Place the above-mentioned device in the Tekno Metal Evaporation Instrument again, and deposit a 6nm gold layer on the surface of the device by electron beam evaporation. At this time, a part of the nano-gold is deposited on the MoS 2 On the thin sheet, a part of the nano-gold is directly deposited on the silicon or silicon dioxide substrate;

[0032] (4) Then place the obtained electrical device in a quartz tube...

Embodiment 2

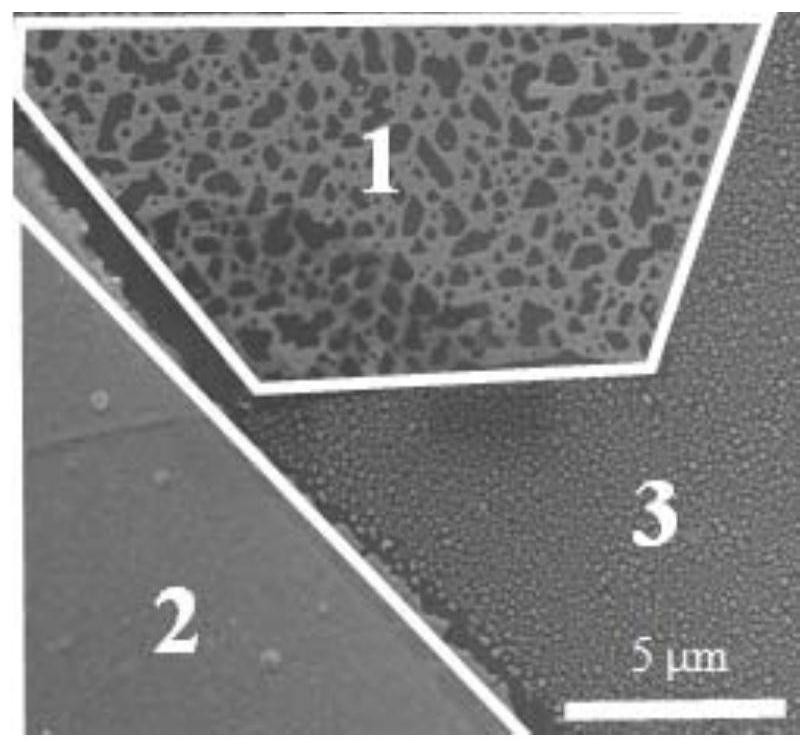

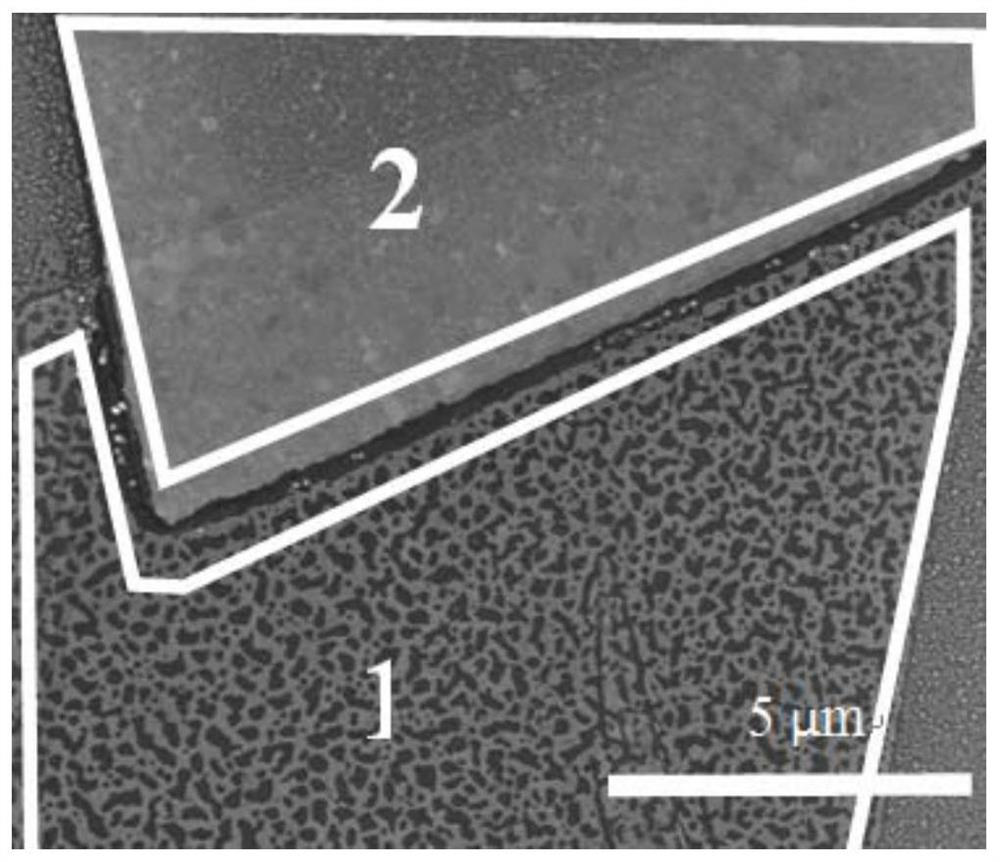

[0035] Using the same method as in Example 1, transfer ReS on heavily doped silicon or silicon dioxide substrates 2 thin slices, and deposited titanium / gold as contact electrodes on both sides of the material by electron beam lithography, and carried out the deposition of nano-gold layer and high-temperature annealing process. The scanning electron microscope image of the prepared sample is shown in image 3 shown. Among them: 1 is ReS 2 Gold on the sheet and surface; 2 is the electrode after annealing treatment; the figure shows the same as MoS 2 samples similar to the ReS 2 A gold nanolayer is formed on the surface of the flake.

[0036] Figure 4 yes yes yes prepared ReS 2 Samples undergo real-time electrical and UV light response test graphs, such as Figure 4 As shown, the ultraviolet light occurs in the area shown in Figure 2, and the current remains at the microampere level after the ultraviolet light is removed. Position 1 in the figure is the time-varying chara...

Embodiment 3

[0038] Using the same method as in Example 1, transfer MoSe on heavily doped silicon or silicon dioxide substrates 2 Thin slices, MoSe2 thin slices, followed by electron beam lithography to deposit titanium / gold on both sides of the material as contact electrodes, and perform nano-gold layer deposition and high-temperature annealing process. For the prepared MoS 2The sample is tested for long-term storage performance of optical signals. The first test time is 1000s. After the test, the sample is placed in a dark room environment, and the test is carried out after three days and seven days respectively. Keep at the microampere level. Curve 1 in the figure is the graph of the sample current changing with time in the air; Curve 2 is the test result after the sample was placed for three days; Curve 3 is the test result after the sample was placed for seven days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com