A terahertz wave optical window with adjustable thermal field and its preparation method and application

An optical window and terahertz wave technology, applied in 3D printing and terahertz wave applications, can solve problems such as real-time response to the external environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Weigh 4g of vanadium dioxide powder, add it to 4g of Dow Corning SE1700 silica gel, and stir evenly to obtain a slurry with a vanadium dioxide content of 50wt.%, and put the slurry into a 10mL barrel for printing.

[0026] 2. Write the 3D printing program of the wood pile structure, set the distance between the medium rods to 700μm, set the number of layers to 8 layers, select a needle with a diameter of 210μm, set the extrusion pressure to 60psi, and the printing speed to 10mm / s, and print layer by layer A preformed terahertz wave optical window is obtained.

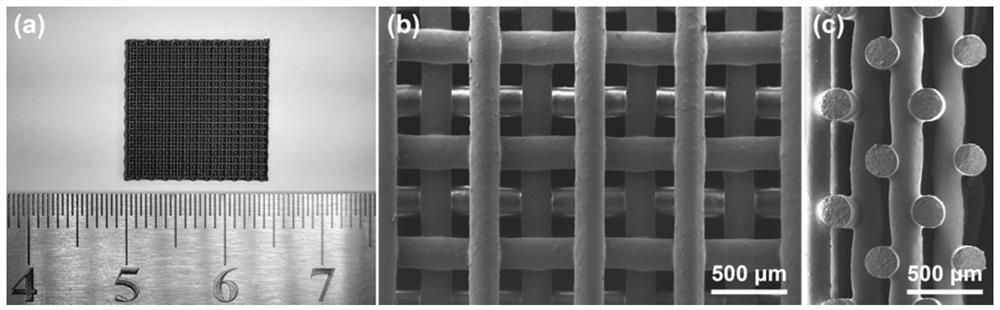

[0027] 3. The preformed optical window is heat-cured at 80° C. for 2 hours to obtain a terahertz wave optical window with a dielectric rod diameter of 210 μm, a pitch of 700 μm, and a number of layers of 8 layers. The structure of the optical window is a three-dimensional wood pile structure, and its optical picture and scanning electron microscope picture are as follows: figure 1 .

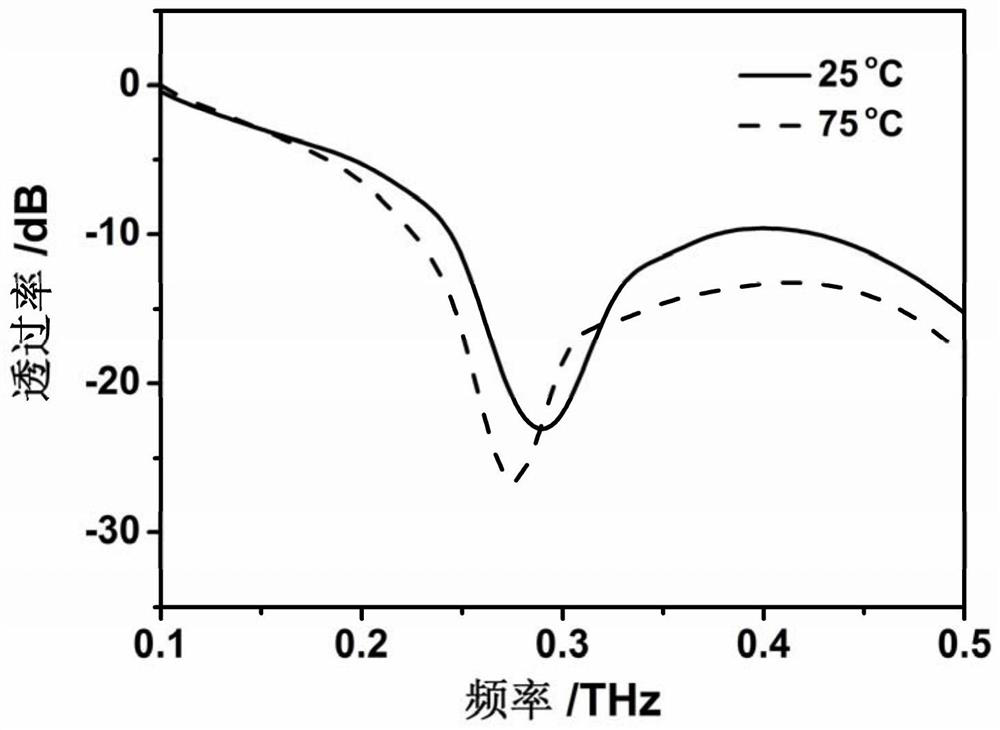

[0028] 4. Perform terah...

Embodiment 2

[0031] 1. Prepare a slurry with a vanadium dioxide content of 50wt.% according to step 1 in Example 1, and put the slurry into a 10mL barrel for printing.

[0032] 2. Write the 3D printing program of the wood pile structure, set the distance between the medium rods to 600μm, set the number of layers to 8 layers, select a needle with a diameter of 210μm, set the extrusion pressure to 60psi, and the printing speed to 10mm / s, and print layer by layer A preformed terahertz wave optical window is obtained.

[0033] 3. The thermal field-tunable terahertz wave optical window with a dielectric rod diameter of 210 μm, a spacing of 600 μm, and a number of layers of 8 layers was obtained by heat-curing the preformed optical window at 80° C. for 2 hours.

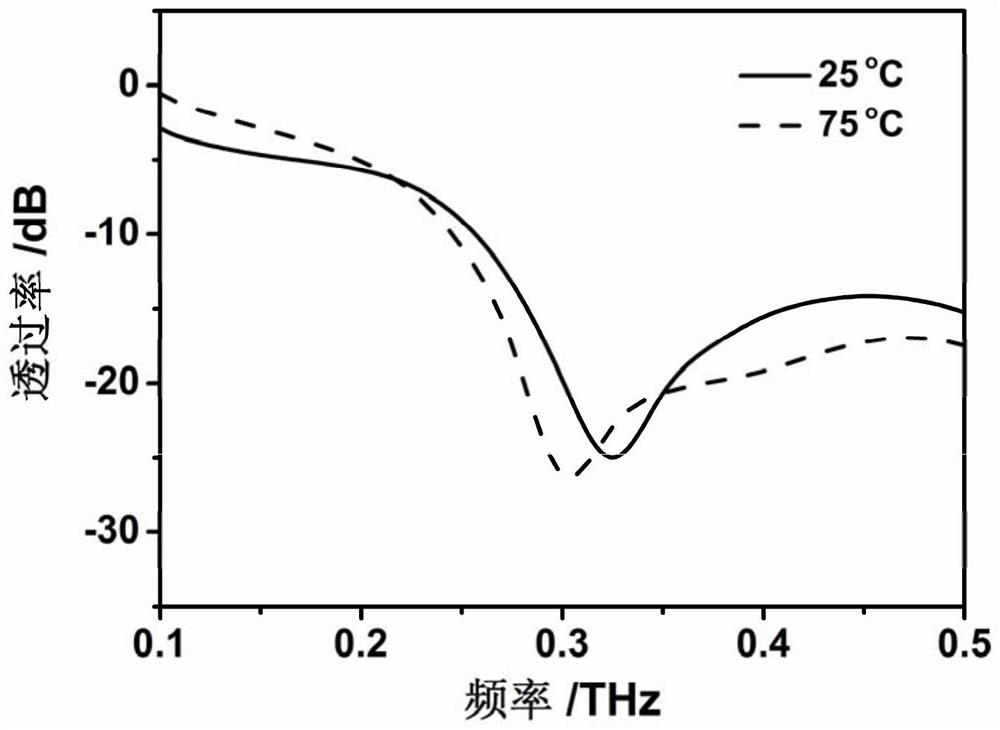

[0034] 4. Perform terahertz time-domain spectroscopy tests on the optical window at 25°C and 75°C respectively, and obtain its photonic bandgap diagram after fast Fourier transform, as shown in image 3 .

[0035] At room temperature ...

Embodiment 3

[0037] 1. Prepare a slurry with a vanadium dioxide content of 50wt.% according to step 1 in Example 1, and put the slurry into a 10mL barrel for printing.

[0038]2. Write the 3D printing program of the wood pile structure, set the distance between the medium rods to 600μm, set the number of layers to 4 layers, select a needle with a diameter of 210μm, set the extrusion pressure to 60psi, and the printing speed to 10mm / s, and print layer by layer A preformed terahertz wave optical window is obtained.

[0039] 3. The thermal field-tunable terahertz wave optical window with a dielectric rod diameter of 210 μm, a spacing of 600 μm, and a number of layers of 4 layers was obtained by heat-curing the preformed optical window at 80° C. for 2 hours.

[0040] 4. Perform terahertz time-domain spectroscopy tests on the optical window at 25°C and 75°C respectively, and obtain its photonic bandgap diagram after fast Fourier transform, as shown in Figure 4 .

[0041] At room temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com