Pulse-current pulse heating and gas-pressure forming device and method for difficult-to-deform alloy pipe fitting

A pulse current, hard-to-deform technology, applied in the field of pulse current pulsation heating and air pressure forming devices, can solve the problems of difficult precise control of flame size, long heating time, high cost, etc., and achieve uniform temperature distribution in the circumferential direction of the pipe and uniform temperature distribution in the circumferential direction , Improve the effect of plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following describes the embodiments of the present invention in detail with reference to the accompanying drawings: this embodiment is implemented under the premise of the technical solution of the present invention, and provides detailed implementation and specific operation procedures, but the scope of protection of the present invention is not limited to the following 的实施例。 Example.

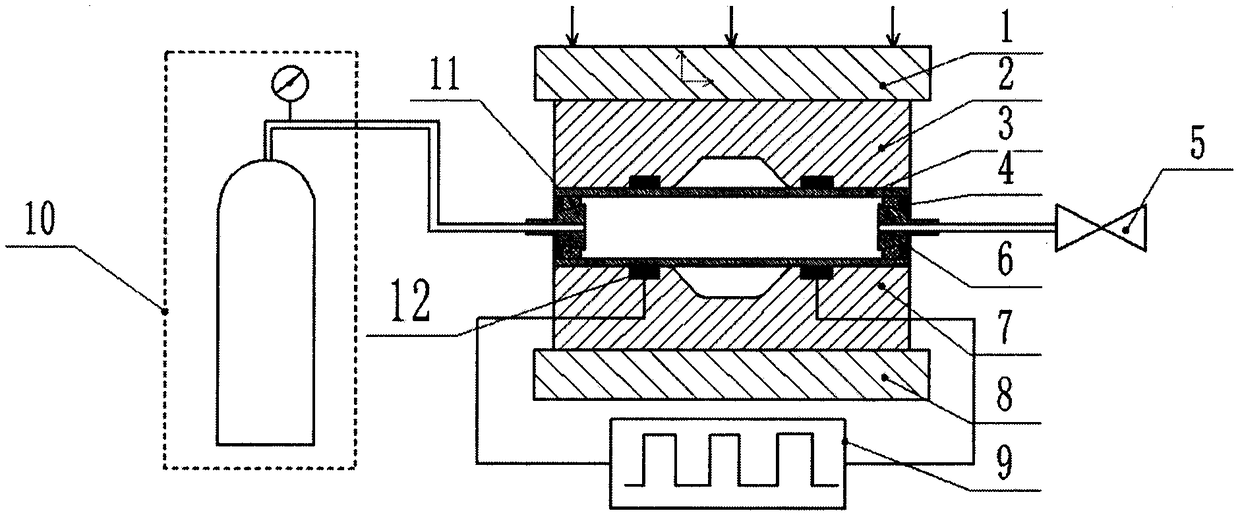

[0022] The pulse current pulsation heating air pressure forming device for difficult-to-deform alloy pipes of the present invention is characterized in that it comprises a high-frequency pulse power supply, an argon gas pressurizing system, an insulating mold, a semicircular electrode, and a pressure head.

[0023] The insulating mold is composed of an upper mold (2) and a lower mold (7). The upper mold (2) and the lower mold (7) are respectively placed on the upper and lower sides of the tube (3) to be bulged. The bulging part is placed in the cavity formed by the upper mold (2) and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com