Mold core of multi-inner-cavity revolving body structural component

A technology for structural parts and revolving bodies, which is applied to the core field of multi-cavity revolving body structural parts, can solve the problems of cracks, radial dimension out of tolerance, affecting the radial concession of the bottom middle core, etc., and achieves good manufacturability, Light weight and good radial concession

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

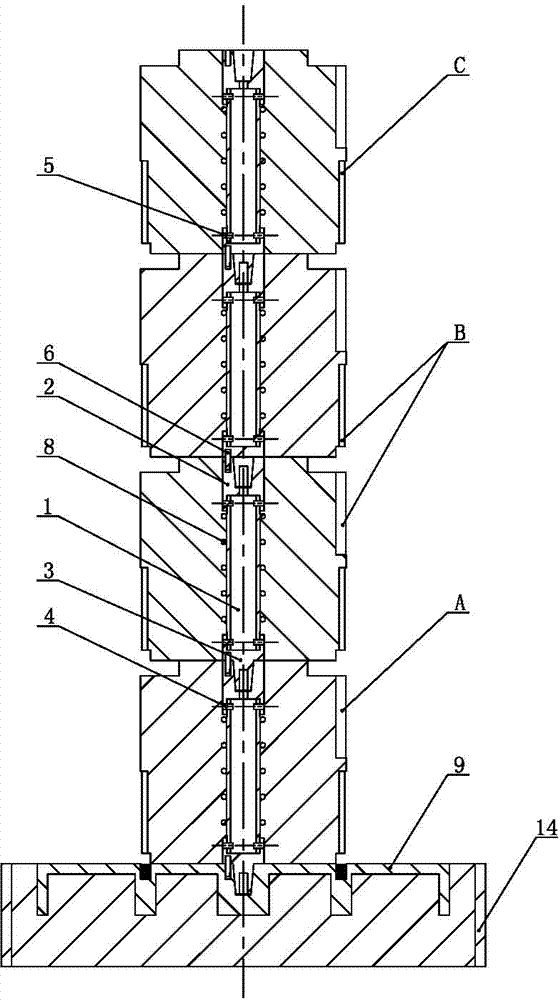

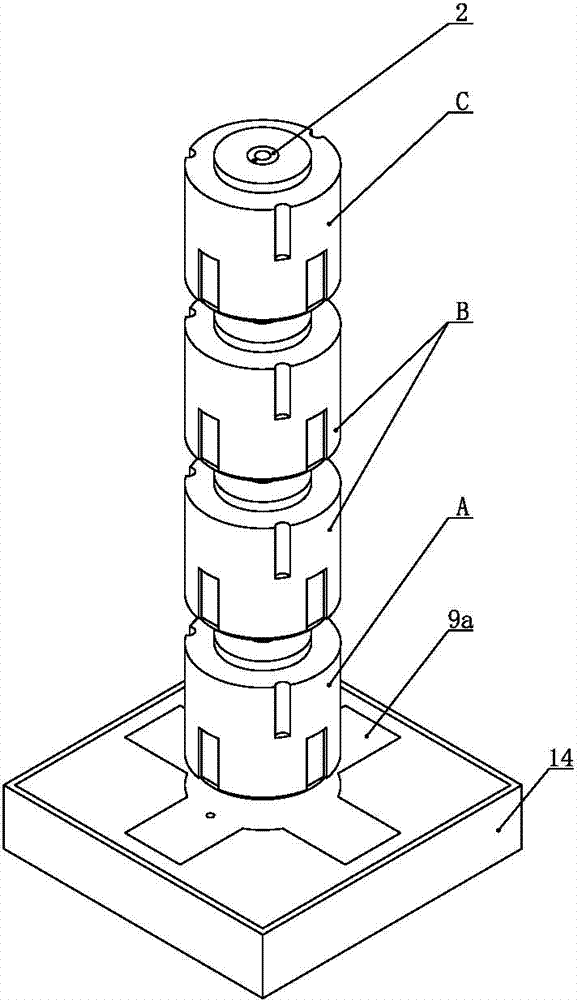

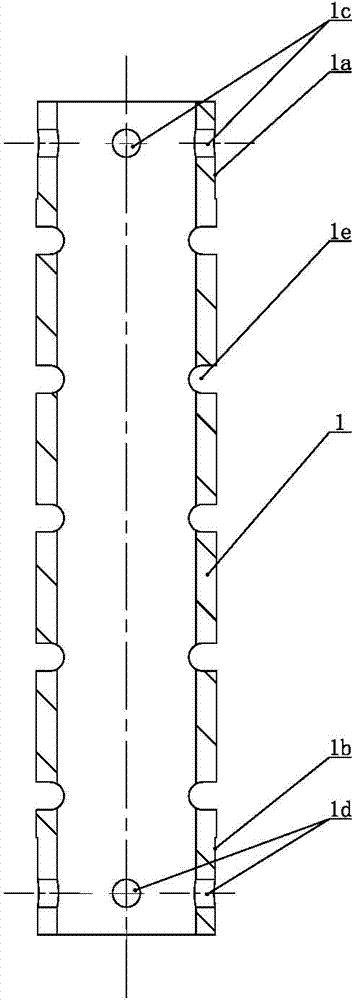

[0047] like figure 1 , figure 2 As shown, the core of the multi-cavity rotary structure of the present invention includes a sand core base 9 embedded in the top of the molding sand of the lower box 14, a bottom sand core A is stacked on the center of the upper end surface of the sand core base 9, and the bottom sand core The middle sand core B is stacked above the middle sand core B, and the top sand core C is stacked above the middle sand core B; the sand core base 9, the bottom sand core A, the middle sand core B and the top sand core C are coaxial; the bottom sand core The shape of A is consistent with the shape of the lower rotary inner cavity of the structural part, the shape of the middle sand core B is consistent with the shape of the middle rotary inner cavity of the structural part, and the shape of the top sand core C is consistent with that of the upper rotary inner cavity of the structural part. The shape is consistent. The middle sand core B includes two or mor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com