Method for toughening composite interlayers by using multiwalled carbon nanotubes

A technology of multi-walled carbon nanotubes and toughened composite materials, which is applied in the field of preparation of multi-walled carbon nanotubes for interlayer toughening of resin-based continuous fiber composite materials, can solve the problems of high cost, changing the stiffness of prepreg layers and Strength, unused and other issues, to achieve the best effect of fracture toughness, precise controllable spraying density, and enhanced fracture toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

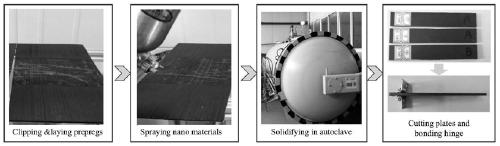

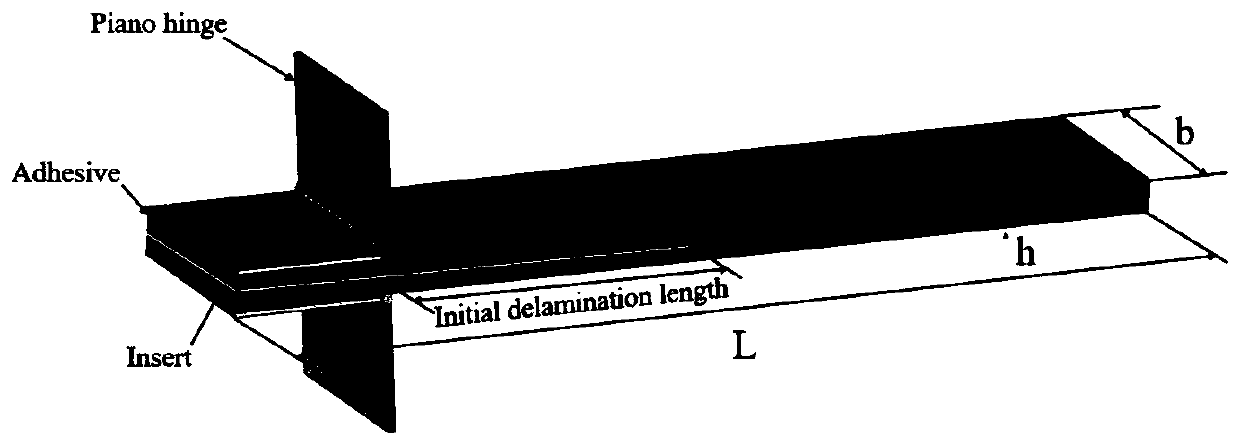

[0025] Multi-walled carbon nanotubes toughened T700 (produced by Toray Corporation of Japan) epoxy resin composite material, specifically comprising the following steps: (1) selecting lower-cost and easier-to-obtain multi-walled carbon nanotubes as the laminated structure layer of the composite material The toughened material between multi-walled carbon nanotubes has an inner diameter of 3-5nm, an outer diameter of 8-15nm and a length range of 3-12μm, and its purity is more than 95wt%, and 0.5g is weighed on a high-precision mass scale; (2) Use the "ultrasonic dispersion method" to fully vibrate and disperse the multi-walled carbon nanotubes in ethanol or acetone, the vibration time is 10-15 minutes, and the temperature is 20°C; (3) After the epoxy resin composite material prepreg is cut , the prepreg surface area is 0.5m 2 , use an air gun with an air source to evenly spray the acetone or ethanol solution dispersed with multi-walled carbon nanotubes on the surface between the...

Embodiment 2

[0027] Multi-walled carbon nanotubes toughened T700 (produced by Toray Corporation of Japan) epoxy resin composite material, which specifically includes the following steps: (1) select lower-cost and easier-to-obtain multi-walled carbon nanotubes as the laminated structure of the composite material The interlayer toughened material has an inner diameter of 3-5nm, an outer diameter of 8-15nm and a length range of 3-12μm, and its purity is more than 95wt%, and 0.2g is weighed on a high-precision mass scale; (2 )Using the "ultrasonic dispersion method" to fully vibrate and disperse the multi-walled carbon nanotubes in ethanol or acetone, the vibration time is 10-15 minutes, and the temperature is 20°C; (3) The epoxy resin composite material prepreg is cut and completed After that, the prepreg surface area is 0.2m 2, Use an air gun with an air source to evenly spray the acetone or ethanol solution dispersed with multi-walled carbon nanotubes on the surface between the layers of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com