Compounds for homeotropic alignment of liquid crystaline media

A compound, fused ring technology, applied in the direction of liquid crystal materials, organic chemistry, chemical instruments and methods, etc., can solve the problem of VA display is not completely satisfactory, achieve low non-uniformity defects, good processability, handling and improved storability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

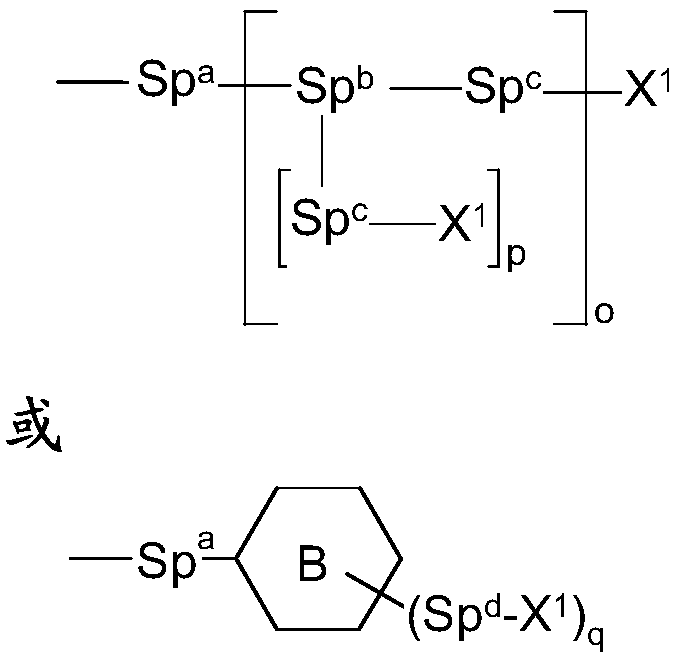

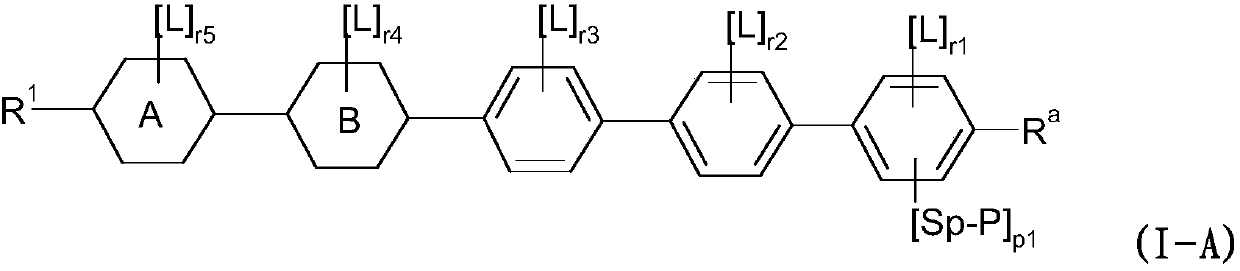

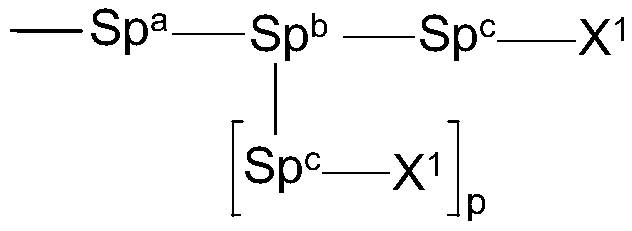

Method used

Image

Examples

Embodiment 1

[0462] Step 1: Synthesis of intermediate 5 (boronic acid)

[0463]

[0464] 9.7 g (0.4 mol) magnesium was covered with 40 ml THF and both were heated to 50°C. A solution of about 10% bromo-aromatic compound 2 (69.9 g, 0.4 mol) in 100 ml THF was then added dropwise. After the reaction had started, 2 was metered in at such a rate that the mixture continued to boil. When the addition was complete, the mixture was cooled to 65°C and 100 g (0.4 mol) of ketone 1 dissolved in 100 ml THF were added dropwise. Work-up yielded 128.3 g of alcohol 3, which was dissolved without further purification in 800 ml of toluene, added 3.2 g of p-toluenesulfonic acid hydrate, and boiled at reflux for 2 hours. Workup yielded 98 g of crude olefin, which was converted to 4 by catalytic hydrogenation.

[0465] 71.7 g (217 mmol) of 4 were dissolved in 200 ml of THF and cooled to -70°C. Then 170 ml (0.239 mol) of a 1.4 molar hexane solution of sec-butyllithium were added dropwise at this temperatur...

Embodiment 2

[0480] Example 2. (Self-aligned Additive No.1)

[0481]

[0482] Phase: glass transition temperature (Tg) -9°C, melting point 80°C.

[0483] 1 H NMR (500MHz, chloroform-d) δ 7.57 (d, J = 1.9Hz, 2H), 7.50 (dd, J = 7.8, 1.9Hz, 2H), 7.38–7.20 (m, 6H), 7.07 (s, 2H), 6.13(t, J=1.3Hz, 2H), 5.58(p, J=1.7Hz, 2H), 4.26(t, J=6.5Hz, 4H), 3.99(t, J=6.3Hz, 2H) , 3.71(s, 4H), 2.96–2.63(m, 9H), 2.55(tt, J=12.1, 3.4Hz, 1H), 2.17–1.84(m, 16H), 1.53(qd, J=12.8, 3.2Hz , 3H), 1.41–1.01(m, 23H), 0.93(dt, J=8.7, 7.0Hz, 6H).

Embodiment 3

[0485]

[0486] Phase: glass transition temperature (Tg) -17°C melting point 65°C

[0487] 1 H NMR (500MHz, chloroform-d) δ 7.58 (d, J = 1.8Hz, 2H), 7.51 (dd, J = 7.9, 2.0Hz, 2H), 7.36–7.21 (m, 6H), 7.07 (s, 2H), 6.14(s, 2H), 5.59(q, J=1.7Hz, 2H), 4.28(t, J=6.6Hz, 4H), 3.95(dt, J=10.4, 5.3Hz, 4H), 3.84( dd, J=10.8, 6.7Hz, 2H), 2.86–2.60(m, 10H), 2.56(tt, J=12.1, 3.4Hz, 1H), 2.15(tt, J=6.5, 4.2Hz, 1H), 2.11 –2.04(m, 4H), 2.03–1.85(m, 12H), 1.54(qd, J=12.8, 3.3Hz, 3H), 1.32(dddd, J=26.7, 15.0, 8.8, 6.3Hz, 9H), 1.20 (td, J=7.5, 4.6Hz, 6H), 1.11 (qd, J=13.1, 3.3Hz, 2H), 0.93 (t, J=7.0Hz, 3H).

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com