Ozone oxidation catalysis catalyst for degrading organic wastewater and preparing method thereof

A technology of ozone catalytic oxidation and organic wastewater, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve high cost, high ozone concentration, and can not reach the national Issues such as the first-class A standard for sewage discharge, to achieve the effect of reducing internal diffusion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

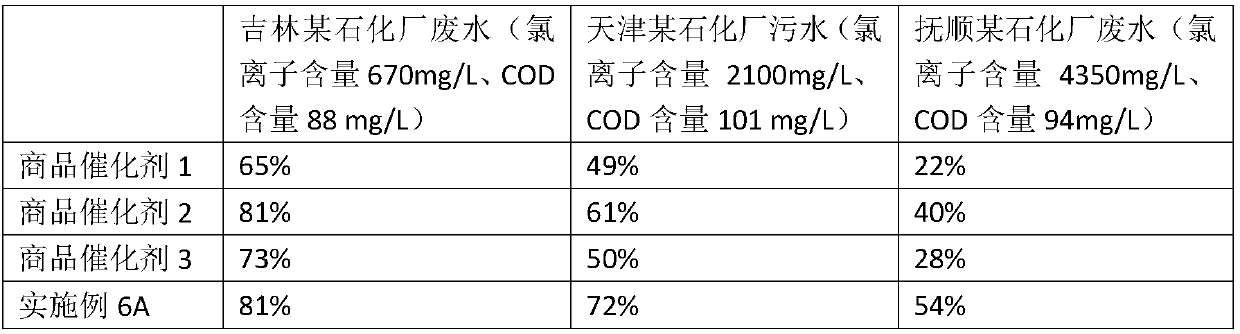

Examples

Embodiment 1

[0110] Example 1 Carrier pretreatment

[0111] Take γ-Al 2 O 3 Particles, soak them in deionized water, and oscillate in an ultrasonic oscillator for at least 20 minutes (usually

[0112] 20-30min), clean to remove dust and impurities on the surface of the carrier; then take out the carrier and put it in an oven for drying treatment. During the drying process, control the drying temperature to be ≥100°C (usually 110±10°C). Dry for at least 4h under the condition of temperature ≥100℃, and dry to constant weight to prepare the pretreated carrier for use.

Embodiment 2

[0113] Example 2 Determination of carrier water absorption

[0114] Weigh the pretreated carrier γ-Al 2 O 3 50g (m, accurate to 0.01g) of particles and placed in a beaker, then add deionized water to the beaker and immerse γ-Al 2 O 3 Granules, stirring for at least 1h (usually 1h) Carrier γ-Al 2 O 3 The particles fully absorb the deionized water; then filter, separate the water from the carrier, and weigh the carrier after absorbing moisture (76g, ml); finally calculate the water absorption rate (Y, %) of the carrier according to formula (1).

[0115] Y(%)=(m 1 -m) / m×100% (1)

[0116] Take the arithmetic mean of the parallel determination results as the determination result, and the absolute value of the error of the two parallel determination results shall not exceed 1%.

[0117] The carrier γ-Al in the specific embodiment of the invention is calculated 2 O 3 The water absorption rate of the particles is 52%, that is, per 100g carrier (γ-Al 2 O 3 ) The amount of water completely absor...

Embodiment 3

[0118] Example 3 Preparation of catalyst (dual catalytically active components)

[0119] 1. Accurately weigh 350g of the catalytic pretreatment carrier γ-Al prepared in Example 1 2 O 3 ,spare.

[0120] 2. The water absorption rate Y of the carrier measured according to Example 2 is 52%, which is converted according to the volume of 1g water per 1ml. Therefore, the water absorption rate of the carrier is 52ml per 100g catalyst carrier, so 350g catalyst The volume of the solution in which the pretreatment carrier is immersed and weighed in an equal volume is 350×52 / 100=182ml.

[0121] 3. Prepare dipping liquid

[0122] Add copper nitrate (29.53g) and ferric nitrate (24.6g) to a small amount of deionized water, stir, and then add deionized water after dissolving until the total volume of the mixed solution is 182ml to make an impregnation solution, namely copper nitrate-iron Solution (182ml), spare, in which the mass of copper nitrate in the immersion solution converted into copper oxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com