Diffusion Method of Monocrystalline Silicon-Based Inverted Pyramid Texture-Like Structure

An inverted pyramid and diffusion method technology, applied in the field of solar cells, can solve problems such as unsatisfactory diffusion effect, and achieve the effect of short processing time and increased production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example 1

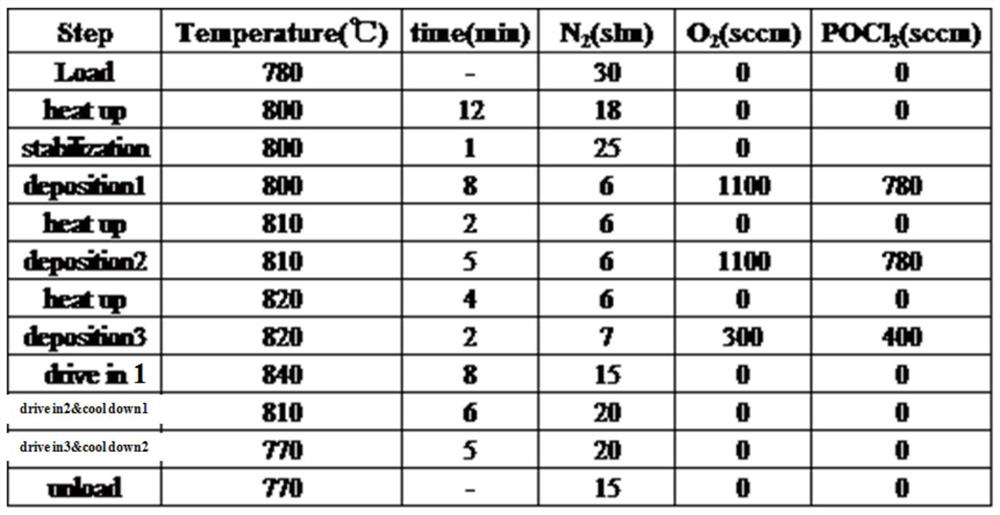

[0057] The key idea of the design of the present invention is: there are three step-by-step source-through deposition steps, and the deposition temperature of each step is gradually increased by about 10°C; the deposition time is gradually decreased from the first step to the third step. The push temperature is 35-50°C higher than the temperature of the first step of via deposition. The cooling step after the phosphorus source is advanced is divided into two steps or not limited to two-step buffer cooling.

[0058] Put the silicon wafer with an inverted pyramid-like structure into a diffusion furnace for step-by-step diffusion; step-by-step diffusion includes phosphorus source deposition under the condition of sequentially increasing temperature and at least two gradient cooling procedures as shown in the table below.

[0059]

[0060] Compared with the diffusion process of the existing positive pyramid textured battery, the present invention has the following beneficial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com