Cuprous oxide-zinc oxide heterojunction solar cell and preparation method thereof

A technology of solar cells and cuprous oxide, which is applied in the field of solar cells, can solve the problems of reducing resistivity, Hall mobility, high interface state defect density, and resistivity reduction, so as to achieve the effect of reducing defect density and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

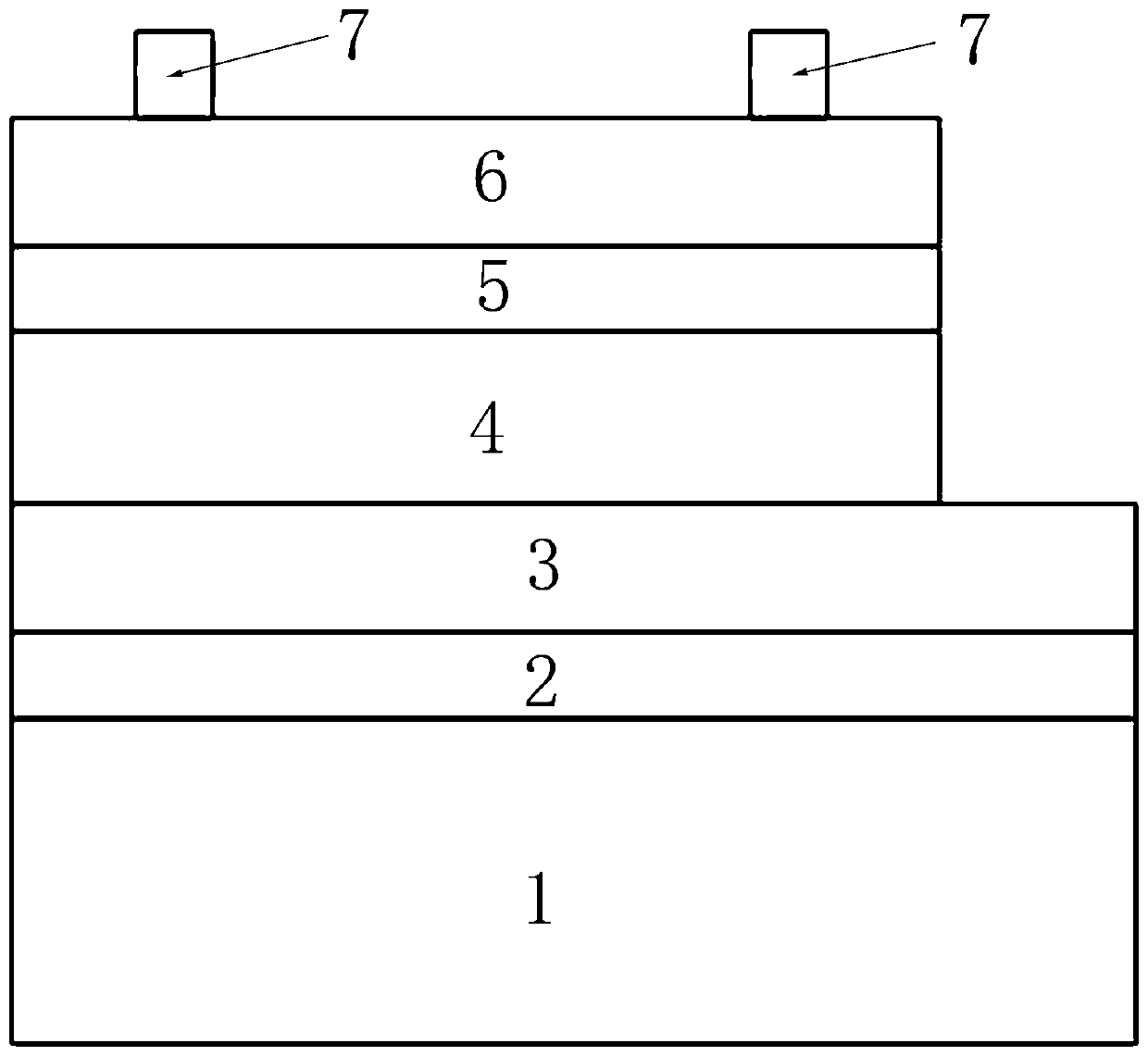

[0020] See attached picture. The solar cell described in this embodiment has the following cell structure: using Corning glass 1 as a substrate, a metal titanium layer 2 (~10nm), a silver layer 3 (~300nm), and a nitrogen-doped cuprous oxide film are grown sequentially. 4 (~800nm), n-type microcrystalline silicon oxide film 5 (~15nm), aluminum-doped zinc oxide film 6 (~200nm), silver electrode 7.

[0021] When preparing:

[0022] 1. Substrate cleaning and bottom electrode preparation

[0023] The substrate is Corning glass 1, the optical transmittance is greater than 92%, the softening temperature is greater than 600°C, the thickness is 0.55mm, and the area is 3×3cm 2 . The substrate was ultrasonically cleaned for 10 minutes with detergent powder, deionized water, isopropanol, ethanol hydrochloric acid, and acetone in order to remove surface organic and inorganic impurities. In order to increase the bonding strength between the metal silver electrode and the glass at the bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorption coefficient | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com