Microporous water-based waterproof gas-permeable film, water-based waterproof gas-permeable textile, and preparation method thereof

A waterproof and breathable membrane, waterproof and breathable technology, applied in the field of water-based waterproof and breathable textiles and its preparation, microporous water-based waterproof and breathable membrane, can solve the problems of product processing and environmental protection, low hydrostatic pressure resistance and moisture permeability, and waterproof Insufficient moisture permeability stability and other problems, to achieve the effect of improved overall moisture permeability, controllable size, and stable waterproof and moisture permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

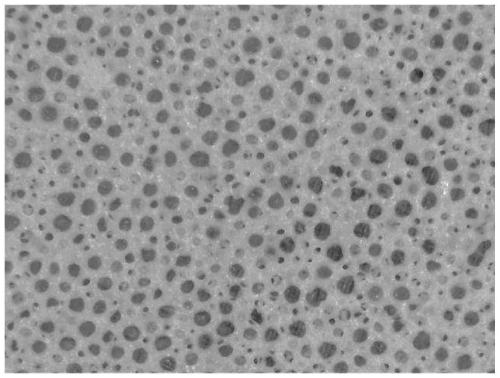

Image

Examples

preparation example Construction

[0033] A preparation method of water-based waterproof and breathable textiles, characterized in that: comprising the steps of:

[0034] (1) Preparation of microporous water-based waterproof and breathable membrane: ① Polyester film pretreatment: Corona treatment is carried out on the polyester film first, and then the surface of the polyester film is coated with silicon wax, and the coating amount of silicon wax is controlled at 10-20g / m 2 , the drying temperature after coating is controlled at 150-170°C;

[0035] ② Preparation of water-based foaming resin: the water-based foaming resin is weighed in proportion and mixed, and then the foaming ratio is controlled at 1:2-2.5 by an air foaming machine, and foamed to obtain a water-based foaming resin;

[0036] ③ Coating and drying: The prepared water-based foaming resin is coated on the pretreated polyester film through a high-precision coating head, and dried at 100-160°C to form a microporous water-based waterproof and breath...

Embodiment 1

[0042] A water-based waterproof and breathable textile, comprising face cloth, water-based high water pressure-resistant polyurethane, water-based foaming resin, water-based high water-pressure resistant polyurethane and a base cloth arranged sequentially from top to bottom.

[0043] A microporous water-based waterproof and breathable membrane, including a polyester film and a water-based foaming resin arranged in sequence from top to bottom, the water-based foaming resin includes the following raw materials in parts by weight: 80 parts of aliphatic water-based polyurethane emulsion with a solid content of 50%, 80 parts of aliphatic water-based polyurethane emulsion, 8 parts of sodium stearate, 2 parts of polyether modified silicone oil, 1 part of ammonia water, 2 parts of ethanolamine, 0.5 parts of sodium dodecylbenzenesulfonate, 0.2 parts of polyvinyl alcohol, 0.4 parts of polyethylene glycol, ethylene glycol 0.5 parts, 0.08 parts of organic bismuth catalyst, 1 part of isocya...

Embodiment 2

[0055] A water-based waterproof and breathable textile, comprising face cloth, water-based high water pressure-resistant polyurethane, water-based foaming resin, water-based high water-pressure resistant polyurethane and a base cloth arranged sequentially from top to bottom.

[0056] A microporous water-based waterproof and breathable membrane, including a polyester film and a water-based foaming resin arranged sequentially from top to bottom, the water-based foaming resin includes the following raw materials in parts by weight: 75 parts of aliphatic water-based polyurethane emulsion with a solid content of 50%, hard 9 parts of sodium fatty acid, 2 parts of polyether modified silicone oil, 1.5 parts of ammonia water, 1.5 parts of ethanolamine, 0.5 parts of sodium dodecylbenzenesulfonate, 0.3 parts of polyvinyl alcohol, 0.4 parts of polyethylene glycol, 0.5 parts of ethylene glycol 0.08 parts of organic bismuth catalyst, 2 parts of amino resin crosslinking agent, 6 parts of poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com