A kind of thermal barrier coating material with core-shell structure and preparation method thereof

A technology of core-shell structure and thermal barrier coating, which is applied in the direction of coating, chemical instruments and methods, metal material coating technology, etc., to achieve the effect of improving structural stability, low thermal conductivity, and good heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] (1) Weigh the raw materials of lanthanum nitrate hexahydrate and cerium nitrate hexahydrate according to the atomic molar ratio of La and Ce at 5:1, dissolve them completely with deionized water, and mix them evenly under the action of magnetic stirring; add 0.02mol / L phosphoric acid dropwise Sodium solution is used as precipitant, pH is 8, stop dropping, magnetically stir to obtain suspension evenly;

[0049] (2) Transfer the suspension to a hydrothermal kettle for hydrothermal reaction, the temperature of the hydrothermal reaction is 180°C, the time of the hydrothermal reaction is 24h, and the precipitate after the hydrothermal reaction is obtained;

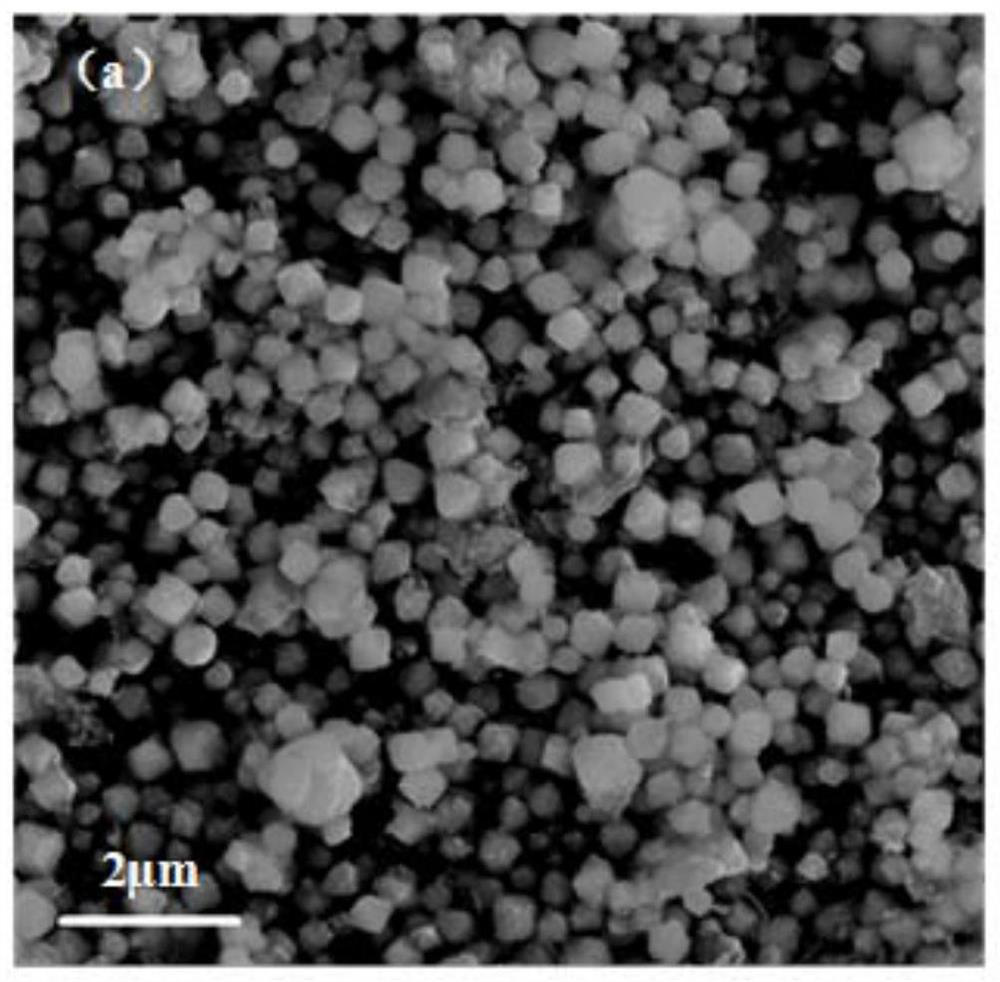

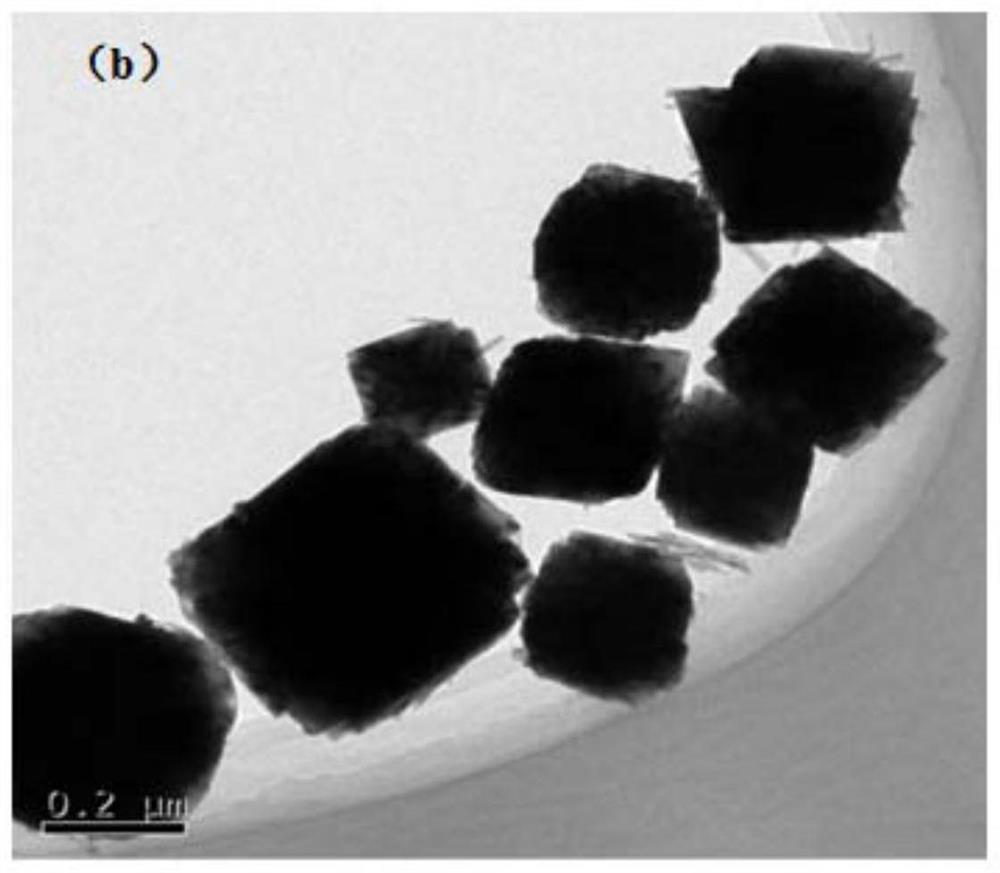

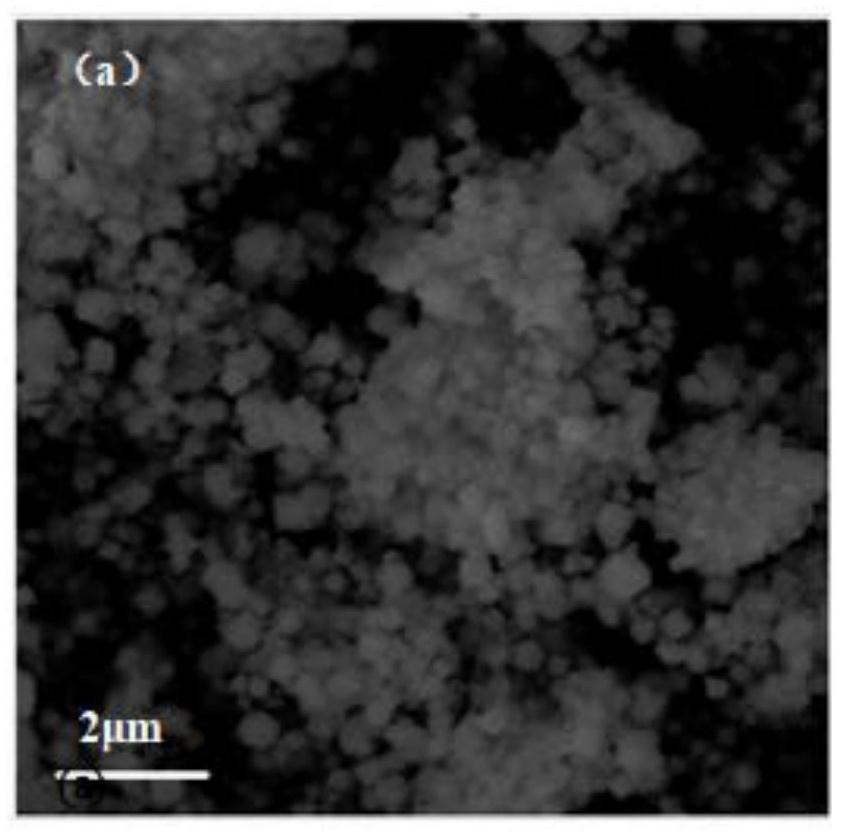

[0050] (3) The precipitate was repeatedly washed with deionized water and absolute ethanol until the pH of the filtrate was 7; the washed precipitate was dried in an oven at 70°C for 12h, and then calcined in a muffle furnace at 500°C for 2h to obtain cerium The lanthanum acid core, the lanthanum cerate core has an octah...

Embodiment 2

[0056] (1) Weigh the raw materials of lanthanum nitrate hexahydrate and cerium nitrate hexahydrate according to the La / Ce atomic molar ratio of 10:1, dissolve them completely in deionized water, and mix them evenly under the action of magnetic stirring; add 0.02mol / L phosphoric acid dropwise Sodium solution is used as precipitant, pH is 8, stop dropping, magnetically stir to obtain suspension evenly;

[0057] (2) Transfer the suspension to a hydrothermal kettle for hydrothermal reaction, the temperature of the hydrothermal reaction is 180°C, the time of the hydrothermal reaction is 24h, and the precipitate after the hydrothermal reaction is obtained;

[0058] (3) The precipitate was repeatedly washed with deionized water and absolute ethanol until the pH of the filtrate was 7; the washed precipitate was dried in an oven for 12 hours, and then calcined in a muffle furnace at 500°C for 2 hours to obtain lanthanum cerate Inner core, the inner core of lanthanum cerate is octahedra...

Embodiment 3

[0064] (1) Weigh the raw materials of lanthanum nitrate hexahydrate and cerium nitrate hexahydrate according to the La / Ce atomic molar ratio of 1:1, dissolve them completely with deionized water, and mix them evenly under the action of magnetic stirring; add 0.02mol / L phosphoric acid dropwise Sodium solution is used as precipitant, pH is 8, stop dropping, magnetically stir to obtain suspension evenly;

[0065] (2) Transfer the suspension to a hydrothermal kettle for hydrothermal reaction, the temperature of the hydrothermal reaction is 180°C, the time of the hydrothermal reaction is 24h, and the precipitate after the hydrothermal reaction is obtained;

[0066](3) The precipitate was repeatedly washed with deionized water and absolute ethanol until the pH of the filtrate was 7; the washed precipitate was dried in an oven for 12 hours, and then calcined in a muffle furnace at 500°C for 2 hours to obtain lanthanum cerate Inner core, the inner core of lanthanum cerate is octahedra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com