Dry-type sand production line and dry-type sand making process

A production line, dry technology, applied in the direction of dissolution, grain processing, mixer, etc., can solve the problems of reuse and sludge stacking, high crushing value, increased production cost, etc., to promote the separation of sand and powder, reduce the content of The amount of powder is good for environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

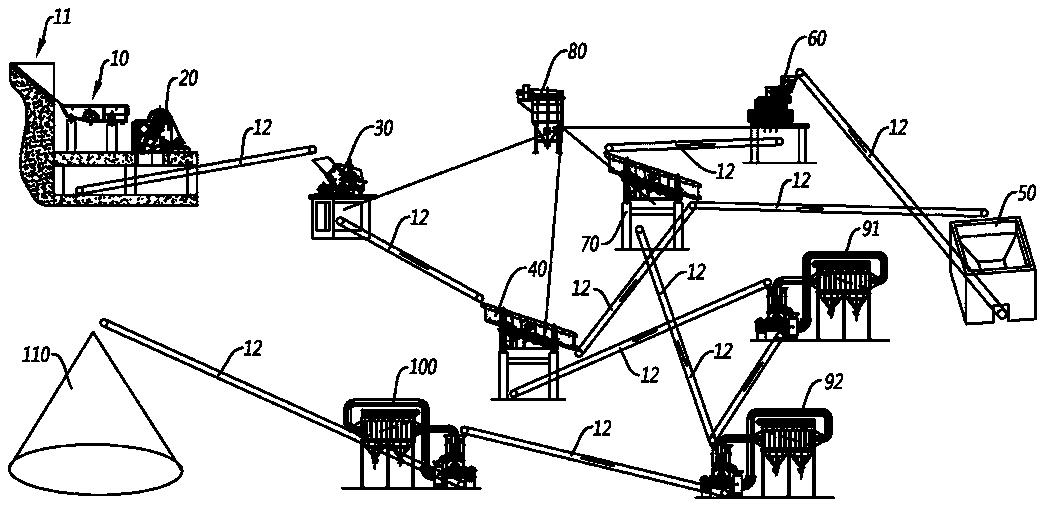

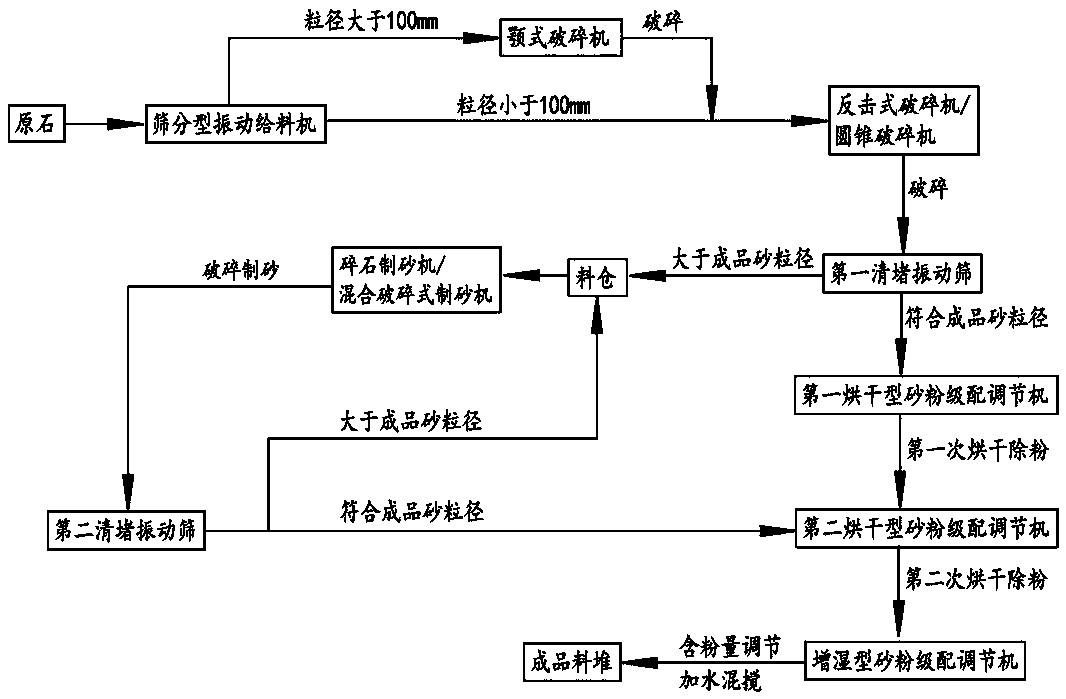

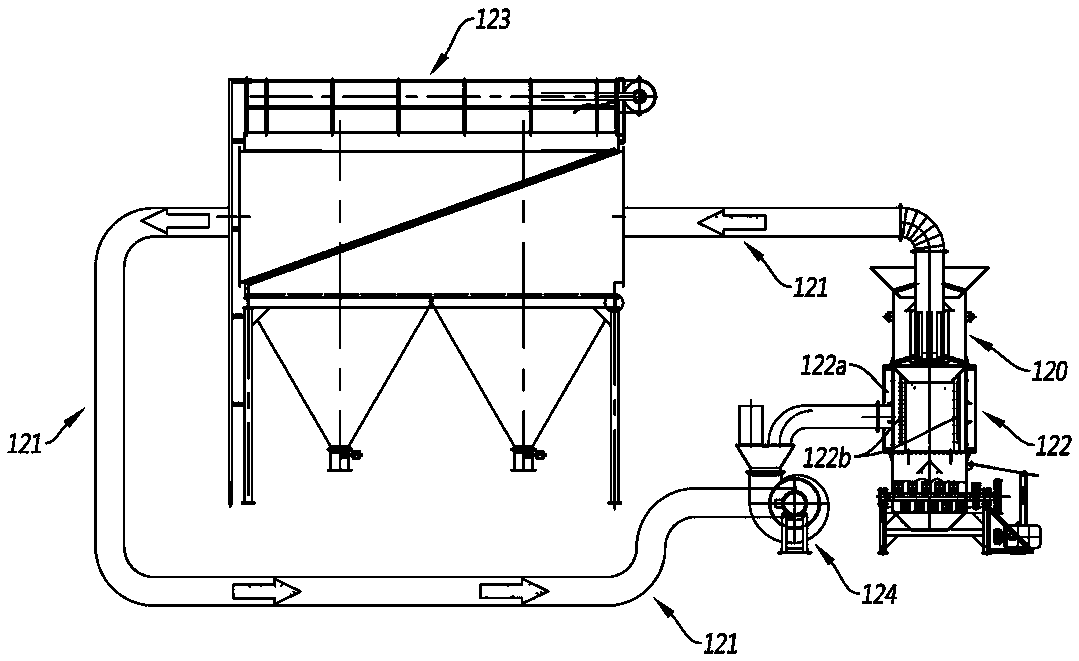

[0044] Such as figure 1 , figure 2 As shown, a dry-type sand production line in a preferred embodiment of the present invention avoids excessive crushing of raw materials through step-by-step crushing and screening, improves the utilization rate of raw materials, and can also precisely control the powder content of sand grains At the same time, by drying and removing powder, the powder content in the sand can be controlled to a low level, which is conducive to the subsequent precise adjustment of the powder content; the dried sand is humidified to adjust the powder content, and mixed with water It is beneficial for the sand powder to stick together, and it is beneficial...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com