Porous profile containing nanometer adsorbent for VOCs treatment and method and equipment of porous profile

A nano-adsorption and adsorbent technology, which is applied in the field of air pollution control, can solve the problems of increased manufacturing cost and operating cost of runner equipment, ineffectiveness of internal zeolite raw powder, and inability to improve the efficiency of runner treatment, so as to avoid stuffiness. The effect of reducing the risk of burning, improving adsorption and desorption efficiency, and reducing gas resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

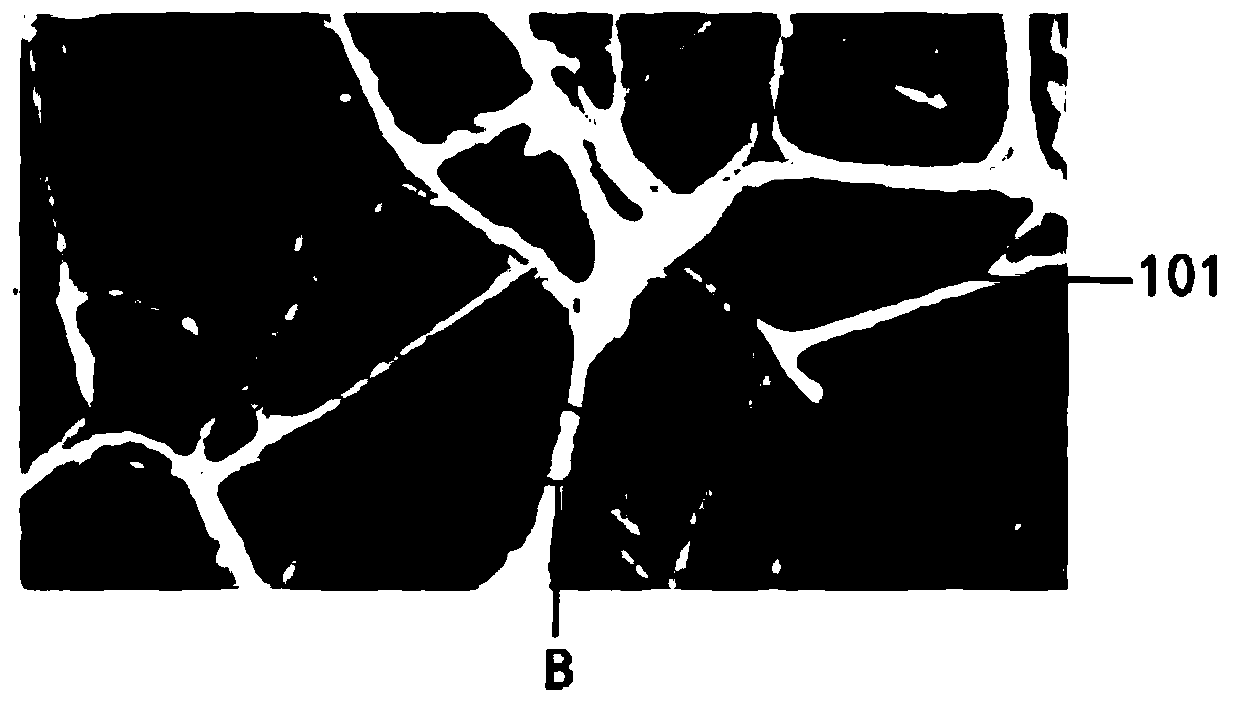

[0060] The preparation method of the zeolite-containing porous profile with melamine foam as the base material (that is, the base skeleton layer 1):

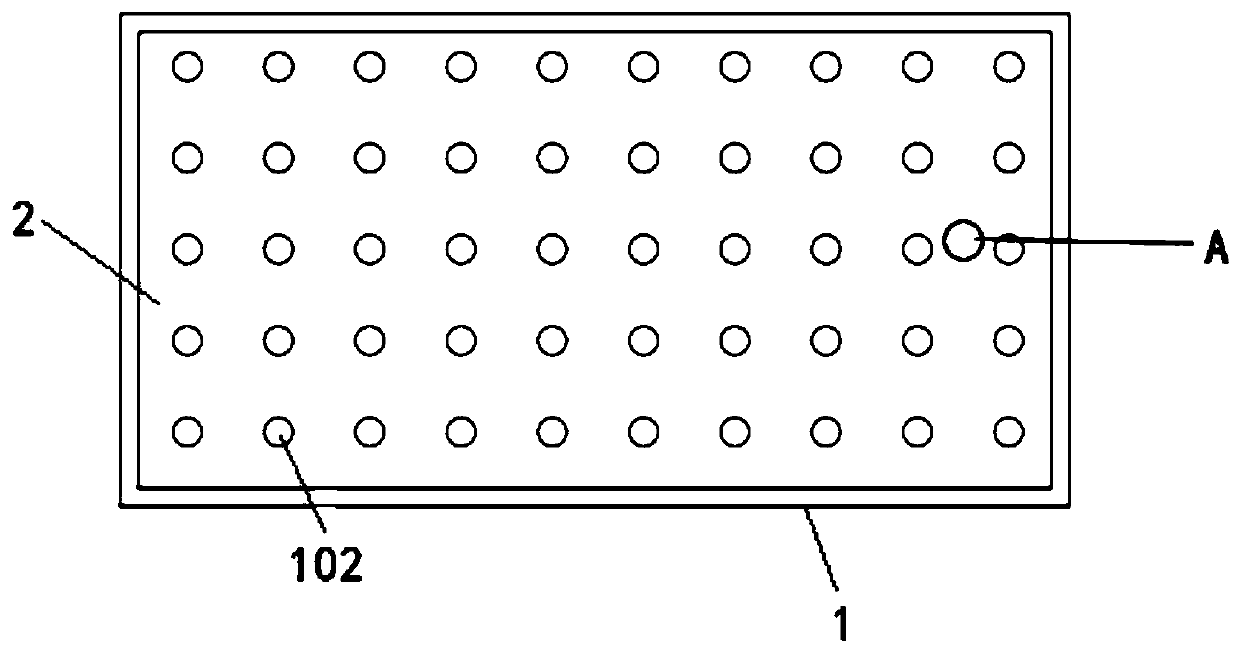

[0061] a) Cut the melamine foam (the typical value of the primary hole diameter is 0.2mm) to a size of 100*100*50mm, and punch holes on it through a punching mold (hole diameter 2mm, number of holes 25*25), the number of holes is 25* 25. Forming secondary channels 102 to prepare a porous melamine foam substrate.

[0062] b) Prepare 2 kg of self-assembled adsorption solution with polydiallyldimethylammonium chloride cationic polyelectrolyte, potassium chloride, and deionized water at a mass ratio of 2:8:90, and stir ultrasonically for 15 minutes.

[0063] c) Immerse the melamine foam porous substrate completely, after soaking for 30 minutes, squeeze out the excess liquid, and put it in a constant temperature box for drying at 75°C.

[0064] d) Prepare high-silicon ZSM-5 zeolite (particle size 2-10 μm), organic silicon sol with a...

Embodiment 2

[0074] The preparation method of the MOF-177 porous profile with melamine foam as the base material (that is, the base skeleton layer 1):

[0075] a) Cut the melamine foam into a size of 100*100*50mm, punch 30*30 holes through a punching mold (aperture 1.5mm, number of holes 30*30), form secondary channels 102, and prepare porous melamine foam Substrate.

[0076] b) Prepare 2 kg of self-assembly adsorption solution with polymethacrylic acid anionic polyelectrolyte, sodium chloride, and deionized water at a mass ratio of 1:6:93, and stir it ultrasonically for 15 minutes.

[0077] c) Completely immerse the melamine foam with a size of 100*100*50mm, soak for 30 minutes, let it stand naturally for 20 minutes to let the excess liquid flow out, and put it in a constant temperature box for drying at 65°C.

[0078] d) 13X zeolite (particle size 5-30 μm), organosilicon sol with a solid content of 20%, attapulgite, deionized water, according to the mass ratio of 10:5:1:33, prepare 2kg ...

Embodiment 3

[0082] The preparation method of the modified active carbon-containing porous profile with melamine foam as the base material (that is, the base skeleton layer 1):

[0083] a) Cut the melamine foam into a size of 100*100*50mm, punch 30*30 holes through a punching mold (aperture 1.5mm, number of holes 30*30), form secondary channels 102, and prepare porous melamine foam Substrate.

[0084] b) Prepare 2 kg of self-assembly adsorption solution with polyethyleneimine cationic polyelectrolyte, ammonium chloride, and deionized water at a mass ratio of 2:6:91, and stir it ultrasonically for 15 minutes.

[0085] c) Immerse the melamine foam cotton with a size of 100*100*50mm completely, soak it for 30 minutes, let it stand naturally for 20 minutes to let the excess liquid flow out, and put it in a constant temperature box for drying at 50°C.

[0086] d) Coconut shell activated carbon carbon powder modified with dilute nitric acid (particle size 5-30 μm, purchase coconut shell activat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com