A circulating greenhouse mechanism based on flue-cured tobacco room

A technology for circulating greenhouses and flue-curing rooms, which is applied in the field of flue-curing rooms, can solve the problems of consuming labor and material resources for a long time, cumbersome procedures, and affecting the efficiency of tobacco leaf curing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

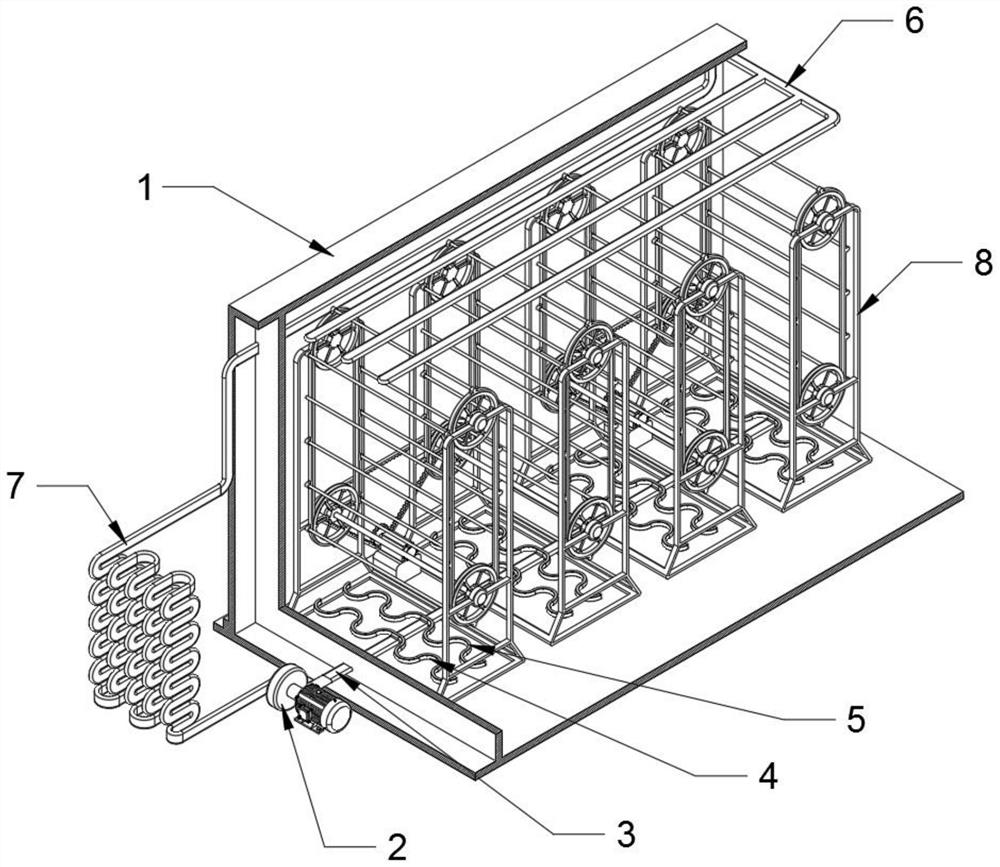

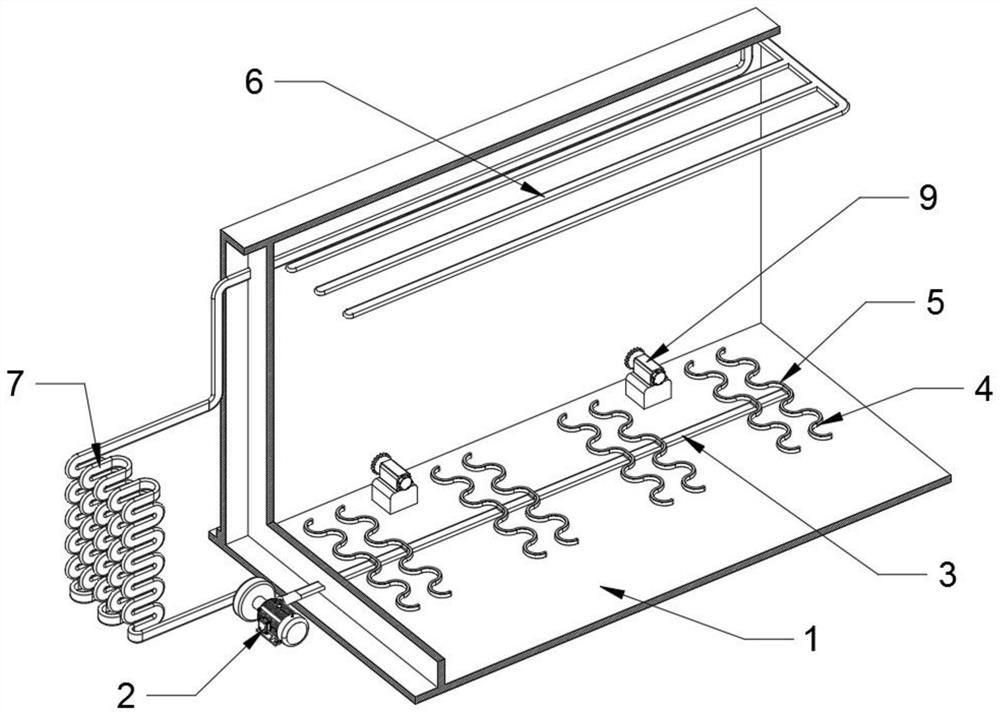

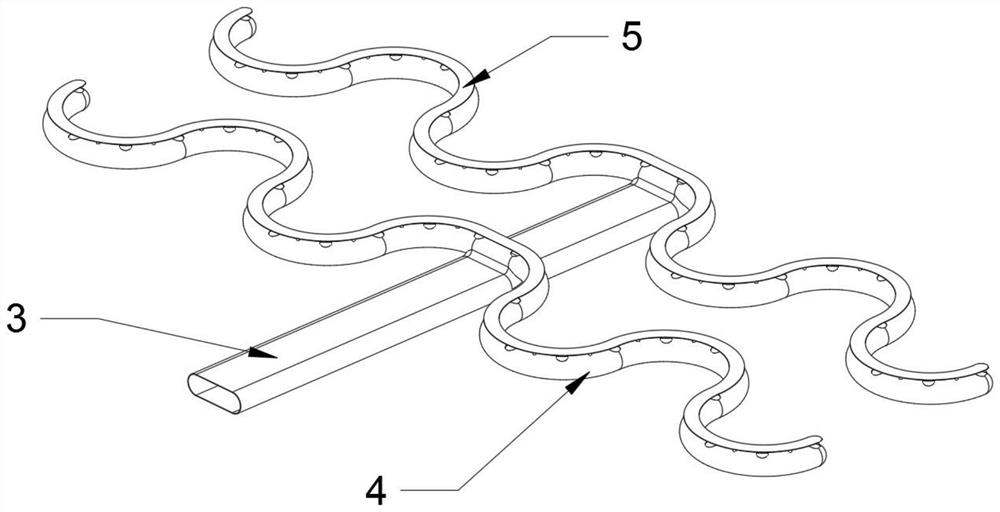

[0027] as attached figure 1 to attach Figure 6 Shown:

[0028] The present invention provides a circulation greenhouse mechanism based on a flue-cured tobacco room, which includes a flue-cured tobacco room 1, a high-temperature fan 2, a heat transfer main pipe 3, a heat exhaust pipe 4, a grille slat 5, an air suction pipe 6, an external heating pipe 7, and a tobacco flue-curing rack 8, Drive motor 9, synchronous transmission belt 10, pulley 11, support belt 12 and suspension bar 13; Described high-temperature blower 2 is positioned at the exterior of flue-cured tobacco room 1, and high-temperature blower 2 is connected with external control circuit by power line, and high-temperature blower 2 The gas outlet is connected to the heat transfer main pipe 3; the heat transfer main pipe 3 is installed in the bottom of the flue-cured tobacco room 1, and the heat exhaust pipe 4 is distributed on the top end surface of the heat transfer main pipe 3; the grid baffle strips 5 have mult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com