Preparation method of self-crosslinking polyimide film

A polyimide film and self-crosslinking technology, which is applied in the field of preparation of self-crosslinking polyimide film, can solve the problem of polyimide film dimensional stability, heat resistance, mechanical properties and solvent resistance And other problems such as poor performance, to achieve good industrialization prospects, simple operation, and the effect that is conducive to mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

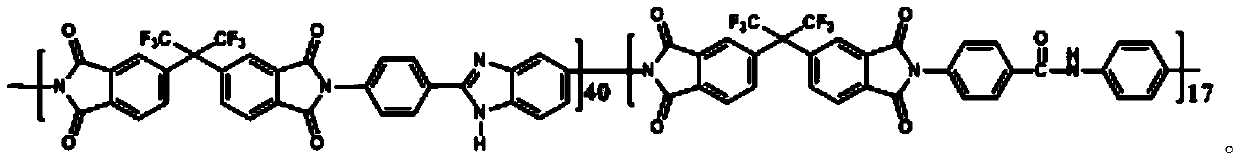

Method used

Image

Examples

Embodiment 1

[0027] (1) Under nitrogen protection, in a three-necked flask, add 250mL of NMP and 8.87g (0.04mol) of 2-(4-aminophenyl)-5-aminobenzimidazole (BIA, Changzhou Sunshine Pharmaceutical Co., Ltd., Analytical pure), 4.42g (0.017mol) of 3-chloro-4,4'-diaminobenzanilide (Changzhou Sunshine Pharmaceutical, analytical pure), 25.1g (0.057mol) of hexafluorodianhydride (Zhejiang Nuo Cheng Technology, analytically pure), stirred and reacted at 5°C for 10h; then raised the temperature to 120°C, 140°C, and 160°C for 1h each, and finally raised the temperature to 190°C for 12h to obtain a high-viscosity polyimide solution.

[0028] (2) Use the polyimide solution prepared in step (1) as the coating slurry, coat the film at a coating speed of 45m / min at 30°C, and dry it under reduced pressure at 50°C to obtain a polyimide film , film thickness is 25 μm. In a nitrogen atmosphere, the obtained polyimide film was heat-treated, thermally cross-linked at 350° C. for 0.5 h, and reacted at 400° C. fo...

Embodiment 2

[0030] (1) Under nitrogen protection, in a three-necked flask, add 300mL of NMP and 12.74g (0.057mol) of 2-(4-aminophenyl)-5-aminobenzimidazole (BIA, Changzhou Sunshine Pharmaceutical Co., Ltd., Analytical pure), 11.17g (0.038mol) of 3,3'-dichloro-4,4'-diaminobenzanilide (Changzhou Sunshine Pharmaceutical, analytically pure), 25.1g (0.095mol) of 3,3 ',4,4'-Benzophenonetetraacid dianhydride (Beijing Malmo Technology Co., Ltd., analytically pure), stirred and reacted at 5°C for 12h; then raised the temperature to 120°C, 140°C, and 160°C for 1h respectively, and finally raised the temperature React at a constant temperature of 190° C. for 16 hours to obtain a high-viscosity polyimide solution.

[0031] (2) Use the polyimide solution prepared in step (1) as the coating slurry, coat the film at a coating speed of 50m / min at 40°C, and dry it under reduced pressure at 50°C to obtain a polyimide film , film thickness is 30 μm. In a nitrogen atmosphere, the obtained polyimide film wa...

Embodiment 3

[0033](1) Under nitrogen protection, in a three-necked flask, add 400mL of NMP and 17.4g (0.078mol) of 2-(4-aminophenyl)-5-aminobenzimidazole (BIA, Changzhou Sunshine Pharmaceutical Co., Ltd., Analytical pure), 13.5g (0.052mol) of 3-chloro-4,4'-diaminobenzanilide (Changzhou Sunshine Pharmaceutical, analytical pure), 41.66g (0.129mol) of 3,3',4, 4'-Benzophenonetetraacid dianhydride (Beijing Malmo Technology Co., Ltd., analytically pure), stirred and reacted at 8°C for 12h; then raised the temperature to 120°C, 140°C, and 160°C for 1h each, and finally raised the temperature to 190°C at a constant temperature After 18 hours of reaction, a high-viscosity polyimide solution was obtained.

[0034] (2) Use the polyimide solution prepared in step (1) as the coating slurry, coat the film at a coating speed of 50m / min at 40°C, and dry it under reduced pressure at 60°C to obtain a polyimide film , film thickness is 30 μm. In a nitrogen atmosphere, the obtained polyimide film was heat-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Initial modulus | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com