A kind of oil well cement suspension type polymer retarder and preparation method and oil well cement slurry system

An oil well cement and polymer technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of oil, gas, water channeling, limiting the scope of application, affecting the quality of cementing, etc., and achieves a small difference in density. , Wide application range, good strength consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

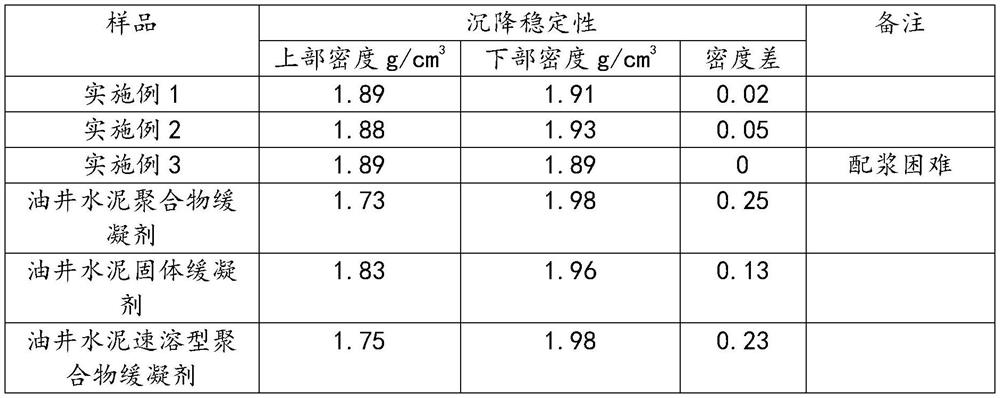

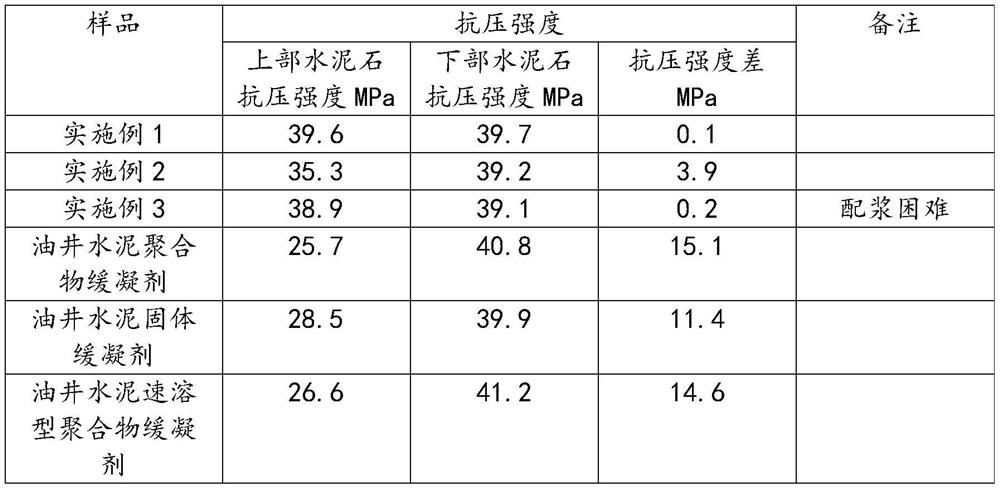

Embodiment 1

[0032] The oil well cement suspension polymer retarder of this embodiment is composed of the following components: 2-acrylamide-2-methylpropanesulfonic acid 300g, itaconic acid 70g, isopropanol 3g, high viscosity carboxymethyl for drilling fluid 3 g of cellulose-based sodium salt (HV-CMC), 150 g of aqueous sodium hydroxide solution with a concentration of 40 wt %, 575 g of deionized water, 5 g of sodium persulfate and 2.5 g of sodium sulfite.

[0033] The preparation method of the oil well cement suspension type polymer retarder of the present embodiment is as follows: 1. first get 20g deionized water and 5g sodium persulfate to be mixed with solution A, get 20g deionized water and 2.5g sodium sulfite to be mixed with solution B, take 147g Deionized water and 3g high-viscosity carboxymethyl cellulose sodium salt (HV-CMC) for drilling fluid [The manufacturer of high-viscosity carboxymethyl cellulose sodium salt (HV-CMC) for drilling fluid is Puyang Zhongyuan Sanli Industrial Co....

Embodiment 2

[0036] The oil well cement suspension polymer retarder of this embodiment is composed of the following components: 2-acrylamide-2-methylpropanesulfonic acid 300g, itaconic acid 70g, isopropanol 3g, high viscosity carboxymethyl for drilling fluid Cellulose sodium salt (HV-CMC) 2g, concentration 40wt% sodium hydroxide aqueous solution 150g, deionized water 575g, sodium persulfate 5g and sodium sulfite 2.5g.

[0037] The preparation method of the oil well cement suspension type polymer retarder of the present embodiment is as follows: 1. first get 20g deionized water and 5g sodium persulfate to be mixed with solution A, get 20g deionized water and 2.5g sodium sulfite to be mixed with solution B, take 147g Deionized water and 2g high-viscosity carboxymethyl cellulose sodium salt (HV-CMC) for drilling fluid [The manufacturer of high-viscosity carboxymethyl cellulose sodium salt (HV-CMC) for drilling fluid is Puyang Zhongyuan Sanli Industrial Co., Ltd. , the product standard is "Car...

Embodiment 3

[0040] The oil well cement suspension polymer retarder of this embodiment is composed of the following components: 2-acrylamide-2-methylpropanesulfonic acid 300g, itaconic acid 70g, isopropanol 3g, high viscosity carboxymethyl for drilling fluid Base cellulose sodium salt (HV-CMC) 4g, concentration is 150g of sodium hydroxide aqueous solution of 40wt%, deionized water 575g, sodium persulfate 5g and sodium sulfite 2.5g.

[0041] The preparation method of the oil well cement suspension type polymer retarder of the present embodiment is as follows: 1. first get 20g deionized water and 5g sodium persulfate to be mixed with solution A, get 20g deionized water and 2.5g sodium sulfite to be mixed with solution B, take 147g Deionized water and 4g high-viscosity carboxymethyl cellulose sodium salt (HV-CMC) for drilling fluid [The manufacturer of high-viscosity carboxymethyl cellulose sodium salt (HV-CMC) for drilling fluid is Puyang Zhongyuan Sanli Industrial Co., Ltd. , the product st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com