Heat treatment methods to suppress recrystallization of 3D printed or welded single crystal superalloys

A heat treatment method and high-temperature alloy technology, applied in the field of additive manufacturing and metal heat treatment, can solve problems such as large residual stress, achieve the effect of improving microstructure, improving mechanical properties, and inhibiting recrystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] This example is an electron beam 3D printing single crystal superalloy. The necessary temperature and necessary time for stress relief annealing are determined in advance as 1100°C / 8 hours, and it is treated according to the heat treatment method described in this patent, namely:

[0069] (a) Clean up the alloy powder adhered to the surface of the 3D printed single crystal superalloy, and remove the surface miscellaneous crystals by grinding with a grinding wheel.

[0070] (b) Perform stress relief annealing, raise the temperature to 1100°C, take it out after 8 hours of heat preservation, and cool to room temperature under the protection of nitrogen.

[0071] (c) Standard heat treatment is performed.

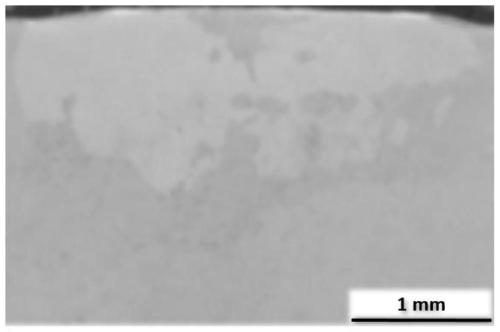

[0072] The treated 3D printed single crystal superalloy slices were prepared for tissue observation and electron backscatter diffraction detection. Such as image 3 As shown, the 3D printed single crystal superalloy sample did not recrystallize after heat treatment accord...

Embodiment 2

[0074] This example is a laser 3D printed single crystal superalloy, and the parameters of the stress relief annealing heat treatment are the same as those in Example 1, which is 1100°C / 8 hours. It is processed by the heat treatment method described in this patent, that is:

[0075] (a) Clean up the alloy powder adhered to the surface of the laser 3D printed single crystal superalloy, and sand the surface to remove the miscellaneous crystal layer.

[0076] (b) Stress-relief annealing is performed on the laser 3D printed single crystal superalloy, and the temperature is raised to 1100 ° C for 8 hours.

[0077] (c) Leave the laser 3D printed single crystal superalloy after stress relief annealing in the heat treatment furnace, change the furnace temperature, and perform standard heat treatment.

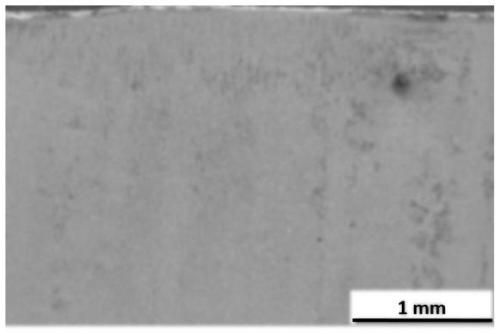

[0078] The treated 3D printed single crystal superalloy slices were prepared for tissue observation and electron backscatter diffraction detection. It was found that the 3D printed sin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com