Eu<3+> doped fluorine niobium tantalite fluorescent powder as well as synthesis and application thereof

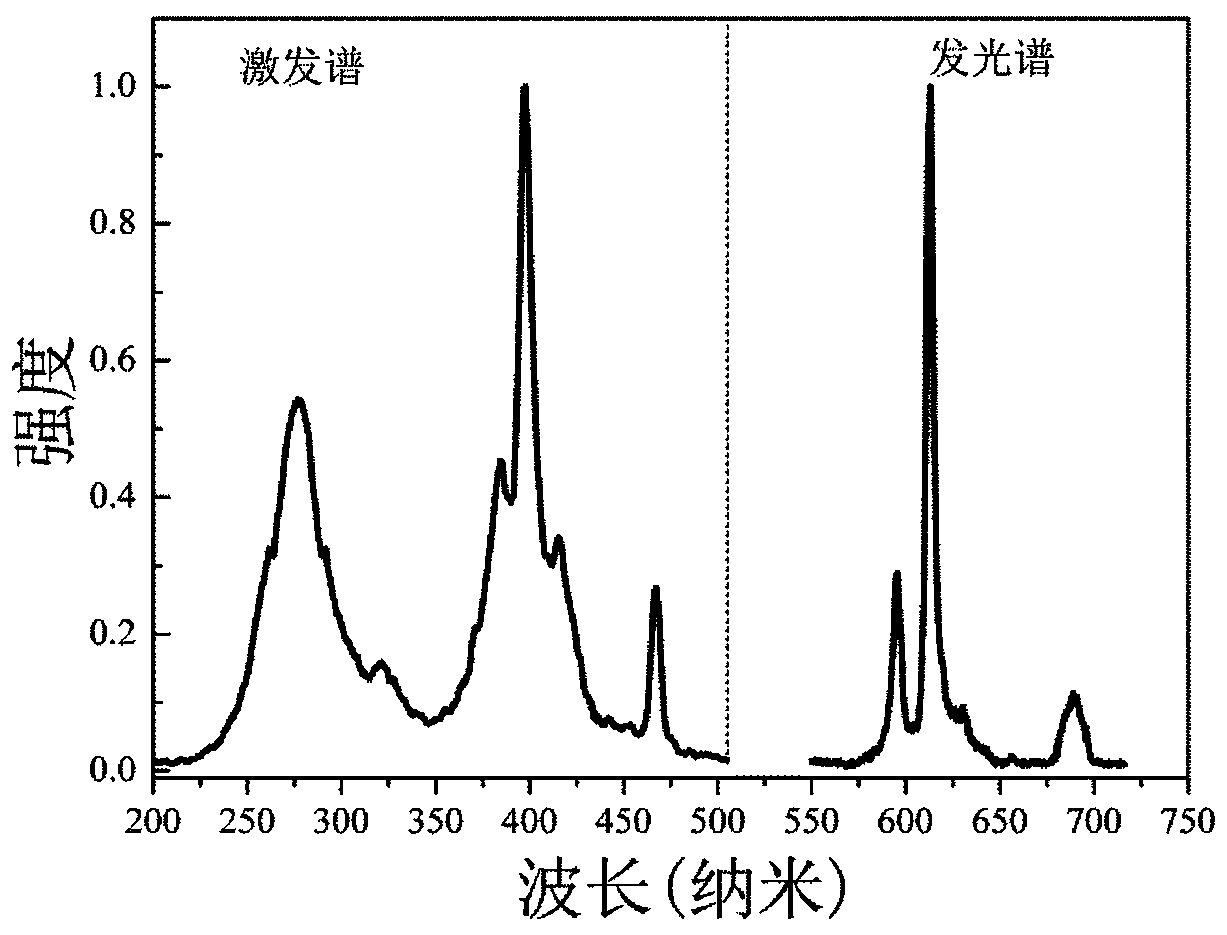

A technology of niobium tantalate and phosphor, applied in the field of fluorine niobium tantalate phosphor and its synthesis and application, can solve the problem of low excitation efficiency, and achieve strong excitation efficiency, enhanced cleanliness, and excellent thermal stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

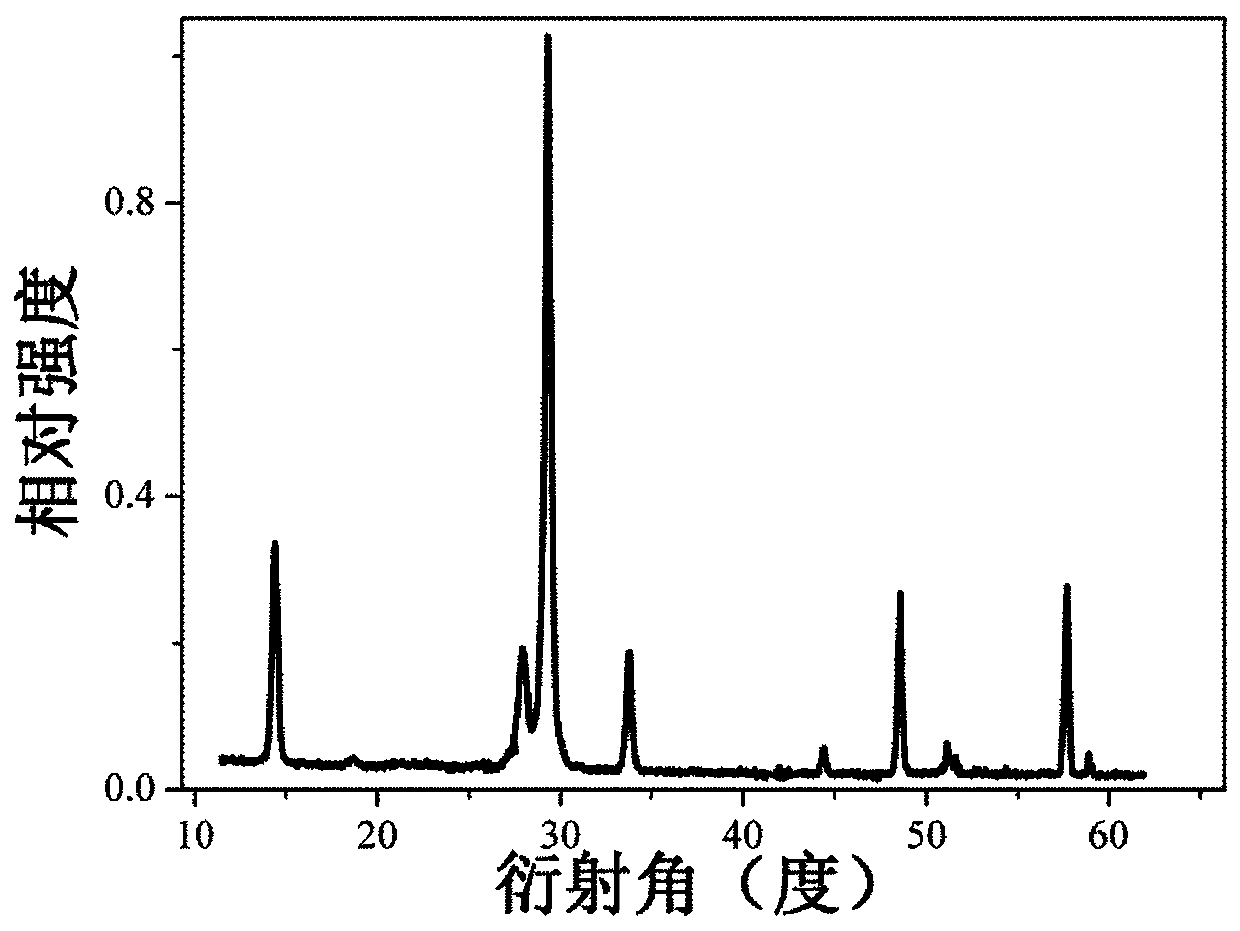

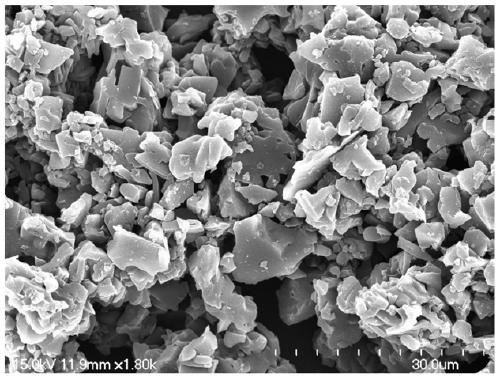

[0030] Example 1: Ca 2.8 Eu 0.2 Nb 2 Ta 1.8 Ti 0.2 o 12 f 2

[0031] According to the chemical formula Ca 1.8 Eu 0.2 Nb 2 Ta 1.8 Ti 0.2 o 12 The stoichiometric ratio of each element is weighed: CaCO 3 : 3.6 g; Eu 2 o 3 : 0.704 g; Nb 2 o 5 : 5.316 grams; Ta 2 o 5 : 7.956 g; TiO 2: 0.32 g; put the weighed raw materials into an agate mortar and grind them carefully to obtain a mixture of these raw materials that is pre-calcined in an air atmosphere at a calcination temperature of 850° C. and a calcination time of 10 hours; put the pre-calcined raw materials obtained again Grind in an agate mortar, press the obtained mixture into a block, and calcinate it twice in an air atmosphere at a temperature of 1400°C for 1 hour, cool naturally, put it into an agate mortar and grind it into a powder, and obtain a pre-calcined mixture.

[0032] According to Ca 1.8 Eu 0.2 Nb 2 Ta 1.8 Ti 0.2 o 12 ·CaF 2 Medium CaF 2 Weigh the molar ratio of CaF 2 : 1.56 g and NH ...

Embodiment 2

[0037] Example 2: Ca 2.994 Eu 0.006 Nb 2 Ta 1.994 Ti 0.006 o 12 f 2

[0038] According to the chemical formula Ca 1.994 Eu 0.006 Nb 2 Ta 1.994 Ti 0.006 o 12 The stoichiometric ratio of each element is weighed: Ca(NO 3 ) 2 : 19.62 g; Eu 2 o 3 : 0.0634 g; Nb 2 o 5 : 15.948 grams; Ta 2 o 5 : 26.44 g; TiO 2 : 0.029 g; put the weighed raw materials into an agate mortar and grind them carefully to obtain a mixture of these raw materials that is pre-calcined in an air atmosphere at a calcination temperature of 1200° C. and a calcination time of 1 hour; put the obtained pre-calcined raw materials Grinding in an agate mortar, the obtained mixture is pressed into a block, and calcined for the second time in an air atmosphere. The calcination temperature is 1200 ° C, and the calcination time is 10 hours. After natural cooling, it is put into an agate mortar and ground into a powder to obtain a pre-calcined mixture.

[0039] According to Ca 1.994 Eu 0.006 Nb 2 Ta ...

Embodiment 3

[0041] Example 3: Ca 2.7 Eu 0.3 Nb 2 Ta 1.7 Ti 0.3 o 12 f 2

[0042] According to the chemical formula Ca 1.7 Eu 0.3 Nb 2 Ta 1.7 Ti 0.3 o 12 The stoichiometric ratio of each element is weighed: CaCO 3 : 5.95 g; Eu 2 o 3 : 1.848 g; Nb 2 o 5 : 9.303 grams; Ta 2 o 5 : 13.15 g; TiO 2 : 0.84 g; put the weighed raw materials into an agate mortar and grind carefully to obtain a mixture of these raw materials that is pre-calcined in an air atmosphere at a calcination temperature of 900° C. and a calcination time of 3 hours; Grinding in an agate mortar, pressing the obtained mixture into blocks, and calcining for the second time in an air atmosphere, the calcining temperature is 1300°C, and the calcining time is 4 hours. The product obtained in the above steps is naturally cooled to obtain a pre-calcined product.

[0043] According to Ca 1.7 Eu 0.3 Nb 2 Ta 1.7 Ti 0.3 o 12 ·CaF 2 Medium CaF 2 Weigh the molar ratio of CaF 2 : 2.73 g and NH 4 F: 1.295 grams; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fluorescence lifetime | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com