Low-temperature anti-corrosion pigment for ceramic wine bottle

A technology for ceramic wine bottles and pigments, which is applied in inorganic pigment treatment, fibrous fillers, synthetic resin layered products, etc. The effect of reducing dissolution and maintaining bright color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

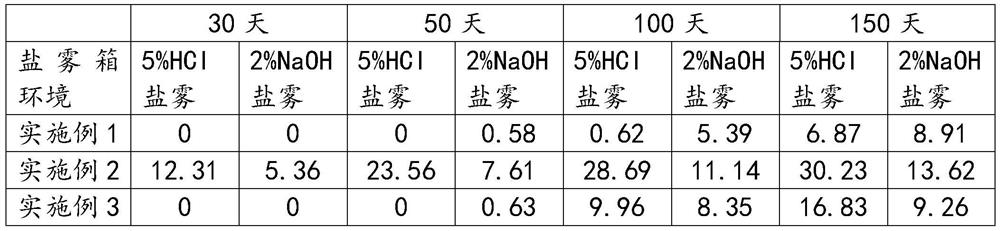

Embodiment 1

[0018] A low-temperature anti-corrosion pigment for ceramic wine bottles, the specific preparation process is as follows:

[0019] Step 1: Weigh 100g of ferric chloride and add it to 1L of water. At the same time, add 11g of polyethylene glycol to the water and stir to dissolve to obtain a reddish-brown emulsion. Then add 15g of diatomaceous earth powder to the 100mL emulsion, and stir and mix for 20-30min , and then filtered and dried, and the dried powder was roasted in a muffle furnace at a temperature of 1000-1050 °C for 5-6 hours to obtain a reddish-brown powder;

[0020] In the second step, add 15 g of the reddish-brown powder prepared in the second step to 100 mL of the reddish-brown emulsion prepared in the first step, stir and mix for 40-50 min at room temperature, then filter and dry, and dry the The powder is placed in a muffle furnace at a temperature of 1000-1050°C and roasted for 5-6 hours to obtain a reddish-brown powder;

[0021] In the third step, the reddish...

Embodiment 2

[0028] A low-temperature anti-corrosion pigment for ceramic wine bottles, the specific preparation process is as follows:

[0029]Step 1: Weigh 100g of ferric chloride and add it to 1L of water. At the same time, add 11g of polyethylene glycol to the water and stir to dissolve to obtain a reddish-brown emulsion. Then add 15g of diatomaceous earth powder to the 100mL emulsion, and stir and mix for 20-30min , and then filtered and dried, and the dried powder was roasted in a muffle furnace at a temperature of 1000-1050 °C for 5-6 hours to obtain a reddish-brown powder;

[0030] In the second step, add 15 g of the reddish-brown powder prepared in the second step to 100 mL of the reddish-brown emulsion prepared in the first step, stir and mix for 40-50 min at room temperature, then filter and dry, and dry the The powder is placed in a muffle furnace at a temperature of 1000-1050°C and roasted for 5-6 hours to obtain a reddish-brown powder;

[0031] In the third step, the reddish-...

Embodiment 3

[0033] A low-temperature anti-corrosion pigment for ceramic wine bottles, the specific preparation process is as follows:

[0034] Step 1: Weigh 100g of ferric chloride and add it to 1L of water. At the same time, add 11g of polyethylene glycol to the water and stir to dissolve to obtain a reddish-brown emulsion. Then add 15g of diatomaceous earth powder to the 100mL emulsion, and stir and mix for 20-30min , and then filtered and dried, and the dried powder was roasted in a muffle furnace at a temperature of 1000-1050 °C for 5-6 hours to obtain a reddish-brown powder;

[0035] In the second step, add 15 g of the reddish-brown powder prepared in the second step to 100 mL of the reddish-brown emulsion prepared in the first step, stir and mix for 40-50 min at room temperature, then filter and dry, and dry the The powder is placed in a muffle furnace at a temperature of 1000-1050°C and roasted for 5-6 hours to obtain a reddish-brown powder;

[0036] In the third step, the reddish...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com