Bismuth oxyiodide composite photocatalytic material modified with carbon-coated ferroferric oxide magnetic microspheres as well as preparation method and application of bismuth oxyiodide composite photocatalytic material

A technology of carbon-coated ferric oxide and ferric oxide, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of high charge recombination rate and agglomeration performance limitations, etc. Achieve the effects of improving photocatalytic performance and corrosion resistance, high yield, promoting separation and transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

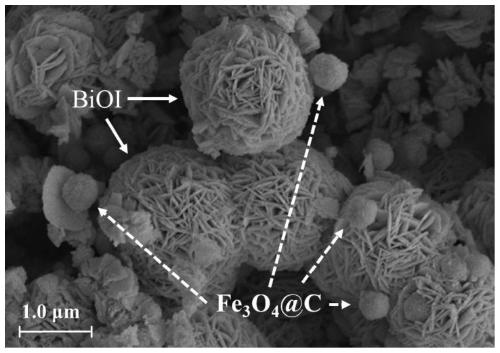

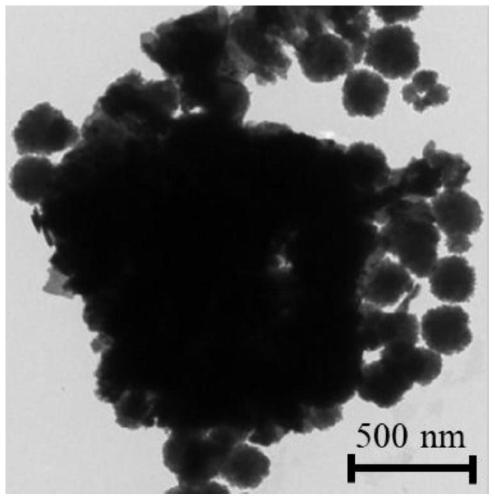

[0061] A yeast carbon-coated ferric oxide microsphere modified bismuth oxyiodide composite photocatalytic material, the composite photocatalytic material is prepared by the following method:

[0062] (1) Cultivate Pichia pastoris in YPD (no agar) culture solution for 48 hours, take it out and centrifuge, wash with deionized water for 2 to 3 times and then centrifuge, then put it in a freeze dryer for - After drying at 50°C for 12 hours, it was made into freeze-dried powder.

[0063] (2) Get respectively 0.2g, 0.3g, 0.4g, 0.5g of Pichia pastoris freeze-dried powder and ferric chloride hexahydrate (FeCl) cultivated in step (1) 3 ·6H 2 (0), anhydrous sodium acetate and sodium acrylate are dissolved in the mixed solvent of 40mL ethylene glycol and diethylene glycol (the volume of two kinds of solvents is 20mL) to obtain mixed suspension, wherein FeCl 3 ·6H 2 O. The dosing concentrations of anhydrous sodium acetate and sodium acrylate are 62.5g / L, 85g / L, and 85g / L, respectively....

Embodiment 2

[0081] The photocatalytic degradation effect of the bismuth oxyiodide composite photocatalyst material modified by yeast carbon-coated iron ferric oxide magnetic microspheres on the photocatalytic degradation of antibiotic tetracycline wastewater was investigated.

[0082]The yeast carbon-coated iron ferric oxide magnetic microspheres modified bismuth oxyiodide composite photocatalytic materials (BF2C2, BF2C3, BF2C4, BF2C5) prepared in Example 1 were applied to the photocatalytic degradation treatment of tetracycline wastewater, and its implementation steps were the same as in Example 2 Same: Weigh 50 mg of BF2C2, BF2C3, BF2C4 and BF2C5 composite photocatalytic materials prepared in Example 1 respectively in a tetracycline simulated wastewater solution with a volume of 50 mL and a concentration of 30 mg / L, and vibrate for 1 h under the condition of avoiding light to make them After reaching the adsorption equilibrium, the photocatalytic degradation reaction was carried out unde...

Embodiment 3

[0084] To investigate the photocatalytic degradation of ciprofloxacin wastewater by yeast carbon-coated iron ferric oxide magnetic microspheres modified bismuth oxyiodide composite photocatalytic material of the present invention.

[0085] Modified bismuth oxyiodide composite photocatalyst material (BF2C3) with the yeast carbon-coated iron ferromagnetic microspheres prepared in Example 1 of the present invention, the pure bismuth oxyiodide (BiOI) material prepared in Comparative Example 1, and the The pure iron ferric oxide magnetic microspheres modified bismuth oxyiodide composite photocatalytic material (BF2) prepared in the ratio 2 is applied to the photocatalytic degradation treatment of ciprofloxacin wastewater, and its implementation steps are similar to those in Example 2: take 50mg respectively The prepared BF2C3, BiOI and BF2 photocatalytic material of embodiment 1, comparative example 1 and comparative example 2 are in the ciprofloxacin simulation waste water solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com