High-specific-heat-capacity heat conducting piece, preparation method and application of high-specific-heat-capacity heat conducting piece

A heat conduction sheet and specific heat capacity technology, which is applied in chemical instruments and methods, heat exchange materials, electrochemical generators, etc., can solve the problems of how to improve the specific heat capacity of heat conduction sheets and the difficulty of specific heat capacity of heat conduction sheets, and achieve excellent heat conduction and absorption Thermal performance, solving heat generation, fast cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

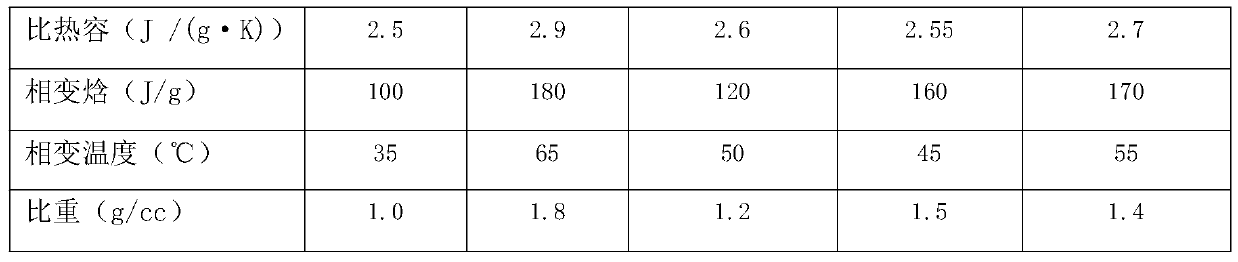

Embodiment 1

[0026] Large specific heat capacity thermal conductive sheet, including the following components by weight: 20 parts of silicone rubber, 1 part of silicone resin, 30 parts of alumina, 10 parts of phosphite, 30 parts of silicon carbide, 0.5 parts of KH5800, 0.5 parts of hydrogen-containing silicone oil And 0.5 parts of platinum catalyst.

Embodiment 2

[0028] Large specific heat capacity thermal conductive sheet, including the following components in parts by weight: 50 parts of silicone rubber, 10 parts of silicone resin, 70 parts of boron nitride, 30 parts of aluminum hydroxide, 70 parts of silicon carbide, 5 parts of KH5805, 5 parts of hydrogen-containing silicone oil and 5 parts of platinum catalyst.

Embodiment 3

[0030] Large specific heat capacity heat conduction sheet, including the following components in parts by weight: 30 parts of silicone rubber, 5 parts of silicone resin, 50 parts of auto-alumina, 20 parts of nitrogen-based flame retardant, 50 parts of silicon carbide, 3 parts of KH5603, 3 parts of hydrogen-containing silicone oil and 2 parts of platinum catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase change enthalpy | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

| Proportion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com