Three-dimensional object forming method and forming device

A technology of three-dimensional objects and molding methods, which is applied in the field of 3D printing, can solve the problems that the mechanical properties of three-dimensional objects are difficult to meet industrial applications, and achieve good mechanical properties, reduce shrinkage, and improve molding accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

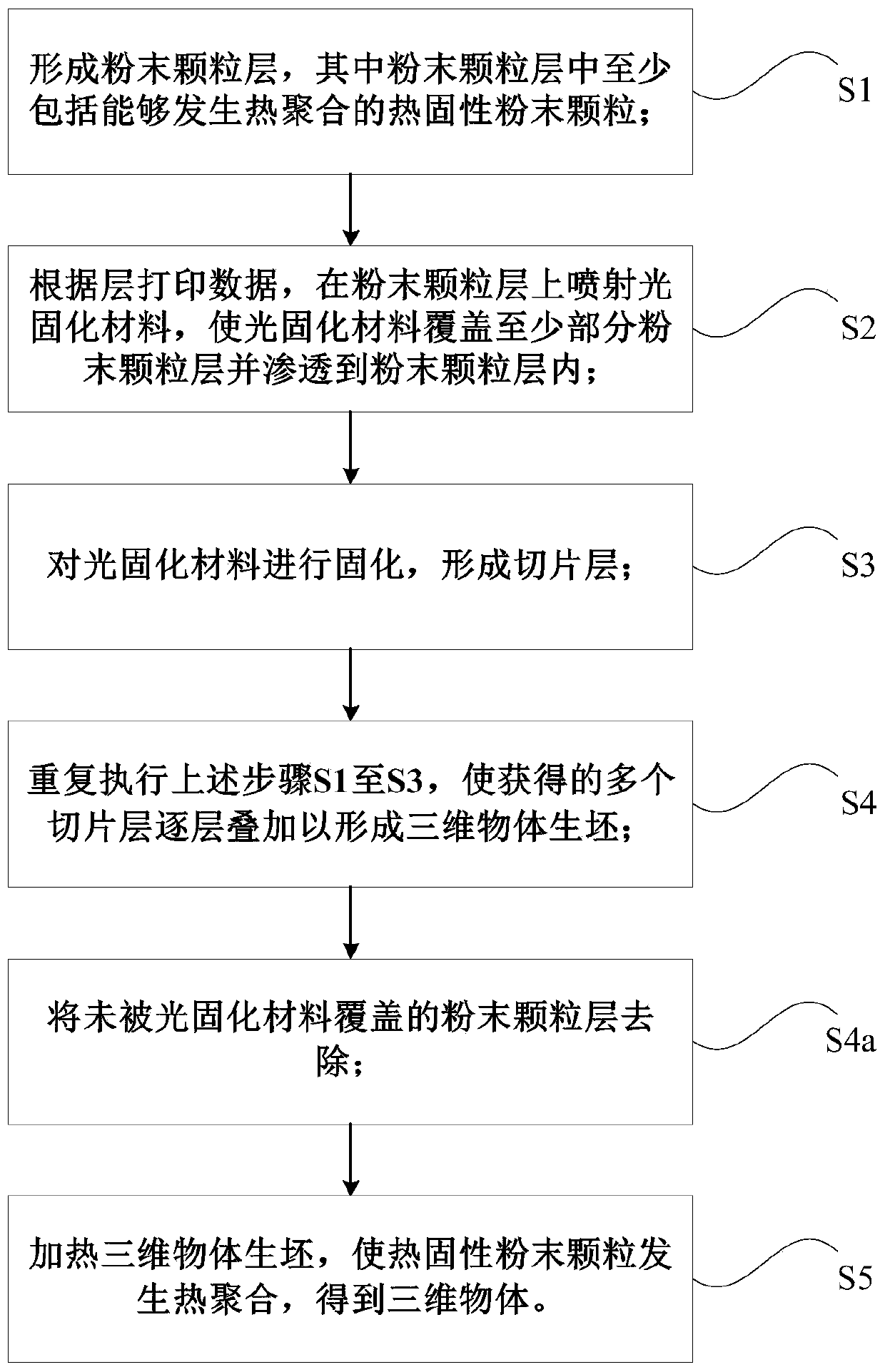

[0033] This embodiment provides a three-dimensional object forming method, such as figure 1 shown, including the following steps:

[0034] S1. Forming a powder particle layer, wherein the powder particle layer contains at least thermosetting powder particles capable of thermal polymerization;

[0035] S2. According to the layer printing data, spray a photocurable material on the powder particle layer, so that the photocurable material covers at least part of the powder particle layer and penetrates into the powder particle layer;

[0036] S3, curing the photocurable material to form a slice layer;

[0037] S4. Repeat the steps from forming the powder particle layer to forming the slicing layer (i.e. steps S1 to S3), so that the obtained multiple slicing layers are superimposed layer by layer to form a three-dimensional object green body;

[0038] S5. Heating the green body of the three-dimensional object to thermally polymerize the thermosetting powder particles to obtain a ...

Embodiment 2

[0095] This embodiment provides a method for forming a three-dimensional object, which is a further description on the basis of the first embodiment. For parts not described in detail in this embodiment, refer to the description in the first embodiment.

[0096] Please refer further figure 1 In this embodiment, after the green body of the three-dimensional object is obtained, step S4a is performed, that is, the powder particle layer not covered by the photocurable material is removed.

[0097] As mentioned earlier, the area and shape of the light-curing material covering and penetrating into the powder particle layer are determined by the layer printing data, so the area of the powder particle layer should at least not be smaller than the area of the light-curing material, so it is difficult to avoid powder particles The layer is not covered and penetrated by the photocurable material. If this part of the uncovered and infiltrated powder particle layer is not removed, it ...

Embodiment 3

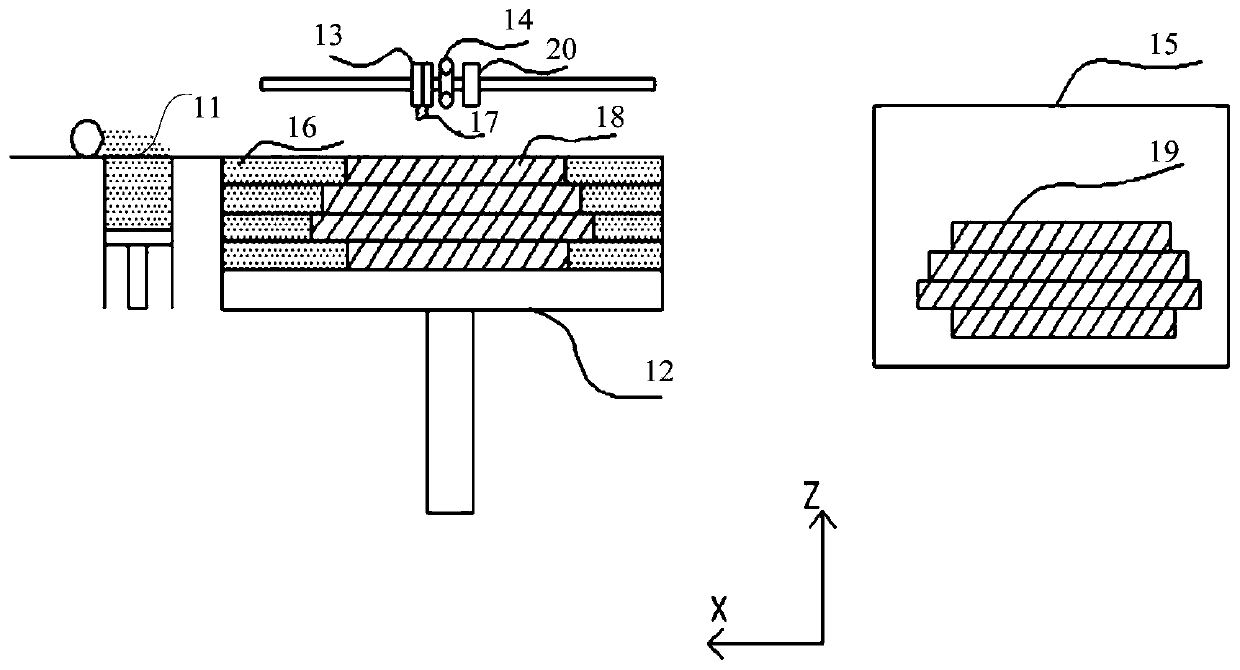

[0101] Such as figure 2 As shown, the present embodiment provides a three-dimensional object forming device, which includes a powder supply component 11, a forming platform 12, an inkjet print head 13, a radiation source 14 and a heating component 15, wherein:

[0102] The powder supply part 11 is used to form a powder particle layer 16 on the molding platform 12;

[0103] The inkjet printing head 13 is used to spray the photocurable material 17 on the powder particle layer 16 according to the layer printing data;

[0104] The radiation source 14 is used to irradiate the photocurable material 17 to cure the photocurable material 17 to form a slice layer 18;

[0105] The heating unit 15 is used to heat the three-dimensional object green body 19 to thermally polymerize the thermosetting powder particles to obtain a three-dimensional object.

[0106] The process of using the three-dimensional object forming device to print three-dimensional objects can be as follows:

[0107]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com