Process for auxiliary agent preparation and direct bonding of aluminum alloy and PP

An aluminum alloy and -PP technology, which is applied in the field of auxiliary agent configuration and aluminum alloy-PP direct bonding process, can solve the problems of less mechanical interlocking and low probability of polymer materials entering aluminum alloy holes, and achieve improved affinity Good waterproof performance and improved bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] An auxiliary agent configuration and an aluminum alloy-PP direct bonding process, comprising the following steps:

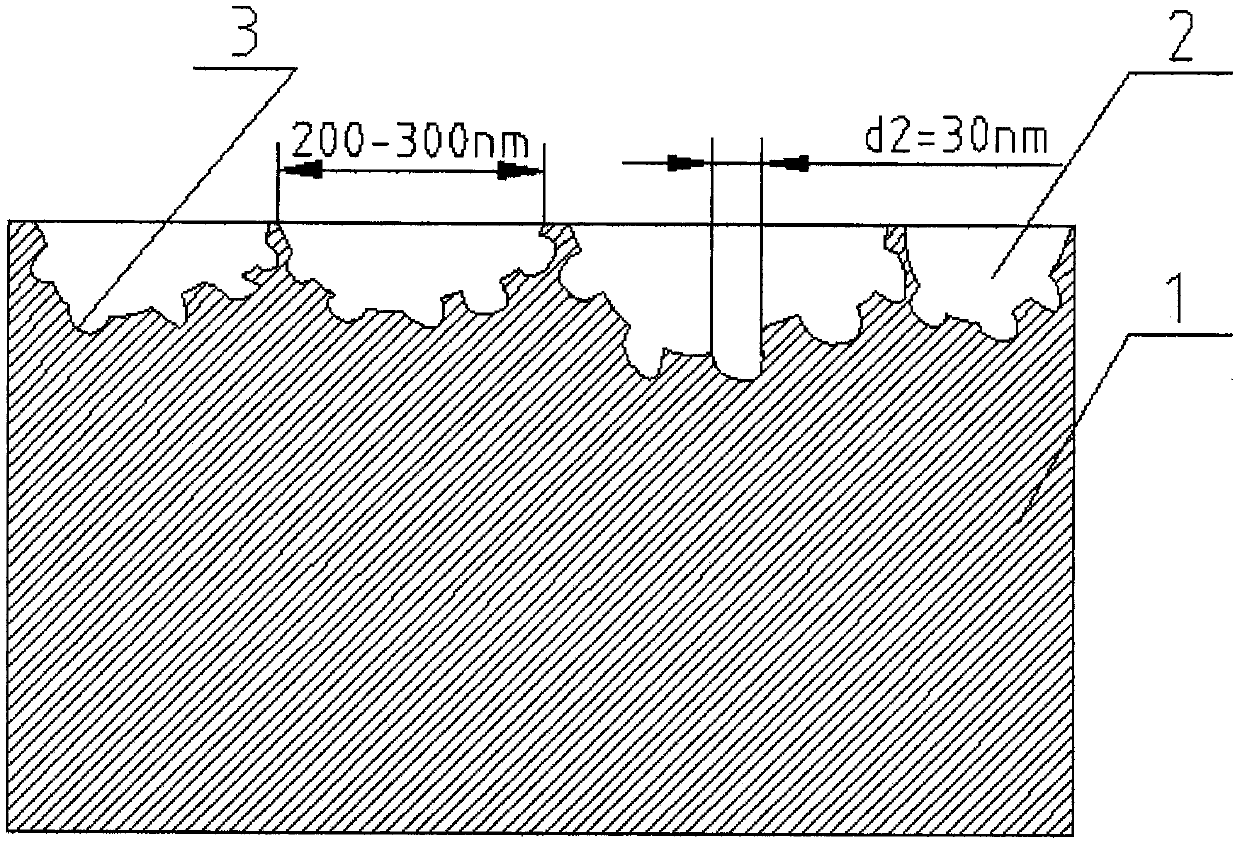

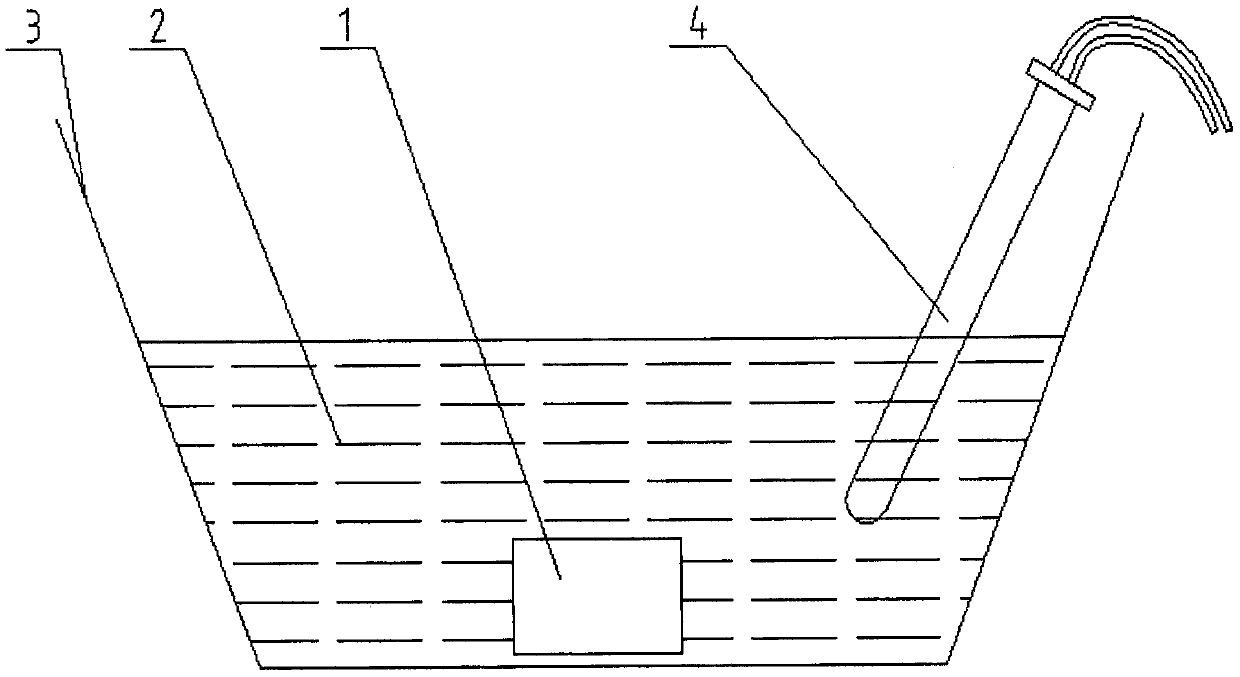

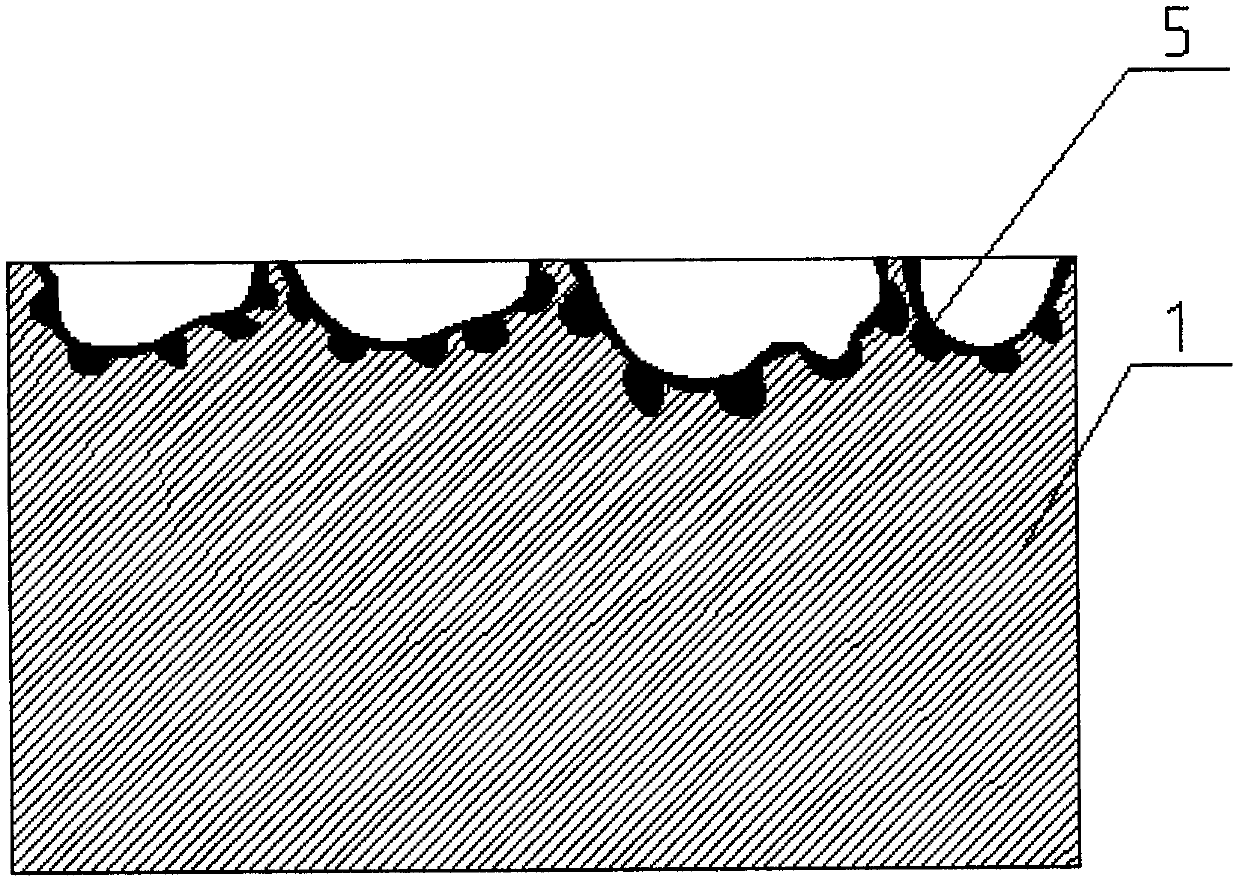

[0035] Step 1: Put the 2A12 aluminum alloy specimen after surface micro corrosion treatment into the ultrasonic working tank. The initial state of the aluminum alloy specimen is as follows: figure 1 As shown, the water temperature does not exceed 25°C, the ultrasonic probe uses 1000Hz, press figure 2 The following operations are performed as shown; the frequency of the ultrasonic probe is treated for 10 minutes to remove the air bubbles in the microscopic holes on the surface of the aluminum alloy test piece, and an auxiliary agent is added to the ultrasonic working tank. The auxiliary agent components include n-octyltriethoxysilane and octyl Trimethoxysilane, the ratio of its parts by mass is 3:5, the volume ratio of the auxiliary agent to the water in the ultrasonic working tank is 1:5, the ultrasonic probe continues to work and stir according to the fr...

Embodiment 2

[0045] An auxiliary agent configuration and an aluminum alloy-PP direct bonding process, comprising the following steps:

[0046] Step 1: Put the 2A12 aluminum alloy specimen after surface micro corrosion treatment into the ultrasonic working tank. The initial state of the aluminum alloy specimen is as follows: figure 1 As shown, the water temperature does not exceed 25°C, the ultrasonic probe uses 1000Hz, press figure 2 The following operations are performed as shown; the frequency of the ultrasonic probe is treated for 10 minutes to remove the air bubbles in the microscopic holes on the surface of the aluminum alloy test piece, and an auxiliary agent is added to the ultrasonic working tank. The auxiliary agent components include n-octyltriethoxysilane and octyl Trimethoxysilane, the ratio of its parts by mass is 3: 7, the volume ratio of the auxiliary agent to the water in the ultrasonic working tank is 1: 5, and the ultrasonic probe continues to work and stir according to th...

Embodiment 3

[0056] An auxiliary agent configuration and an aluminum alloy-PP direct bonding process, comprising the following steps:

[0057] Step 1: Put the 2A12 aluminum alloy specimen after surface micro corrosion treatment into the ultrasonic working tank. The initial state of the aluminum alloy specimen is as follows: figure 1 As shown, the water temperature does not exceed 25°C, the ultrasonic probe uses 1000Hz, press figure 2 The following operations are performed as shown: the frequency of the ultrasonic probe is treated for 10 minutes, the air bubbles in the microscopic pores on the surface of the aluminum alloy specimen are removed, and additives are added to the ultrasonic working tank. The additive components include n-octyltriethoxysilane and octyl Trimethoxysilane, the ratio of its parts by mass is 1:3, the volume ratio of the auxiliary agent to the water in the ultrasonic working tank is 1:5, the ultrasonic probe continues to work and stir according to the frequency of 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com