A kind of multistage quartz sand sorting method

A quartz sand, multi-stage technology, applied in cleaning methods and appliances, chemical instruments and methods, cleaning methods using liquids, etc., can solve problems such as different mesh sizes, substandard particle size distribution of finished sand, and health threats

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 14

[0046] The difference from Example 1, as attached figure 2 As mentioned above, only the structure of the water spray disc 8 used in step B is different. Specifically, the water spray disc 8 is rotatably connected to the water supply pipe, and the water spray holes on the same water spray disc 8 are inclined along the same direction of the circumference of the water cavity. The water spray disc 8 is pushed by the water flow in a counterclockwise (or counterclockwise) direction, thereby rotating. A sand cleaning hole is provided at the bottom of the water spray plate 8. In order to reduce the shunting of the sand cleaning hole, only one sand cleaning hole is provided in this embodiment, and a sand cleaning pipe 11 is bonded to the sand cleaning hole. The sand pipe 11 is a rubber pipe, and the outlet of the sand cleaning pipe 11 faces the root of the water supply pipe.

[0047] Since the bottom of each sorting cavity is set as a cone that guides the sand, the sand will flow al...

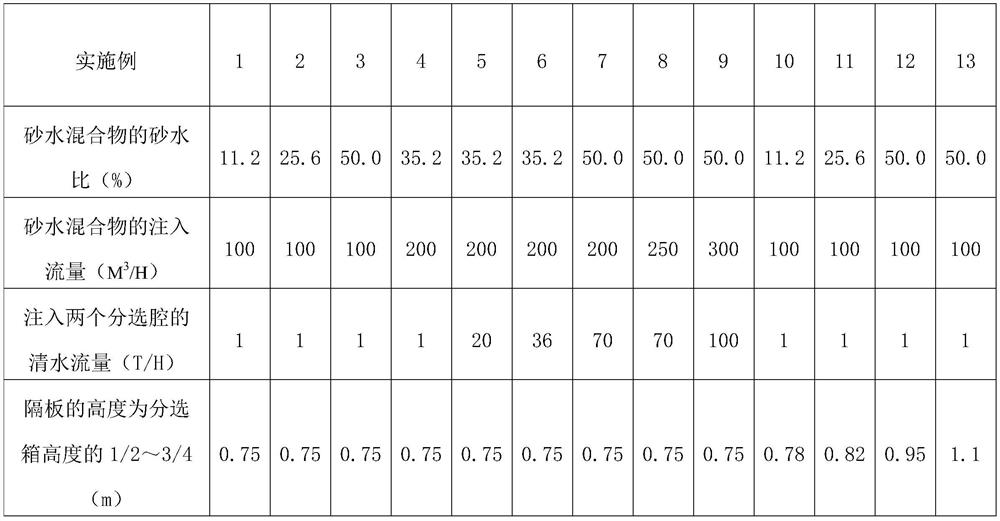

Embodiment 7

[0053] In Example 7 and Example 8, the injection flow rate of the injected sand-water mixture was changed, that is, the component force in the horizontal direction was increased, the horizontal component force increased, and the quartz sand particles in the sand outlet gradually increased, then the horizontal component force The particle size of the quartz sand in the sand mouth has a great influence.

Embodiment 8

[0054] In Example 8 and Example 9, the injection amount of the sand-water mixture increased, the flow rate of clean water increased, and the particle size of the quartz sand particles in the sorting box 1 and the sand outlet increased. To sum up, the sorting of quartz sand particles is affected by the horizontal component force (the injection flow rate of the sand-water mixture) and the vertical component force (the fresh water flow rate injected into the sorting box 1 ).

[0055] In Example 10 to Example 13, the height of the partition was gradually increased, that is, the resistance of the horizontal component force (the injection flow rate of the sand-water mixture) was gradually increased, and the horizontal component force was reduced. The particle size of the quartz sand particles gradually decreases, and the particle size of the quartz sand in the two sorting chambers 2 gradually increases. From the sorting results of Example 14, it can be seen that after changing the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com