Preparation method of self-supporting three-dimensional porous carbon negative electrode material

A carbon negative electrode material, three-dimensional porous technology, which is applied in the field of preparation of self-supporting three-dimensional porous carbon negative electrode materials for sodium ion batteries, can solve the problems of high technical difficulty and cost, reduced battery capacity, difficult industrialized production, etc., and achieves improved electron conduction. High efficiency, high safety and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

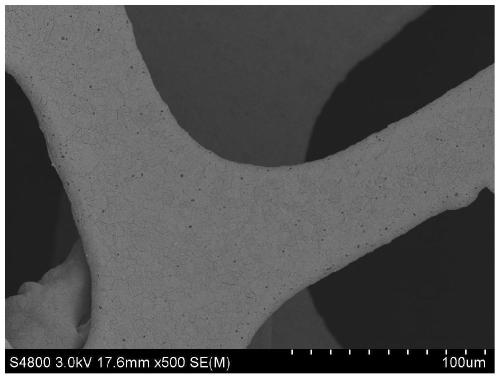

[0031] 1) Dissolve sucrose in a mixed solvent of acetone and deionized water with a volume ratio of 1:9, and stir thoroughly to obtain a 0.02mol / L precursor solution;

[0032] 2) Take a nickel foam self-support body with a length of 40mm, a width of 25mm, and a thickness of 1.0mm, and then ultrasonically clean it with deionized water, acetone, hydrochloric acid with a concentration of 2mol / L, and ethanol for 30min, 50min, 8min, and 40min, and then vacuum-dry it at 80°C 12h, then add the dried nickel foam self-supporting body and precursor solution into a polytetrafluoroethylene-lined reactor, and react hydrothermally at 180°C for 18h;

[0033] 3) After the reaction, cool down to room temperature naturally, wash the product 6 times with deionized water and absolute ethanol, and dry it in a vacuum oven at 80°C for 24 hours;

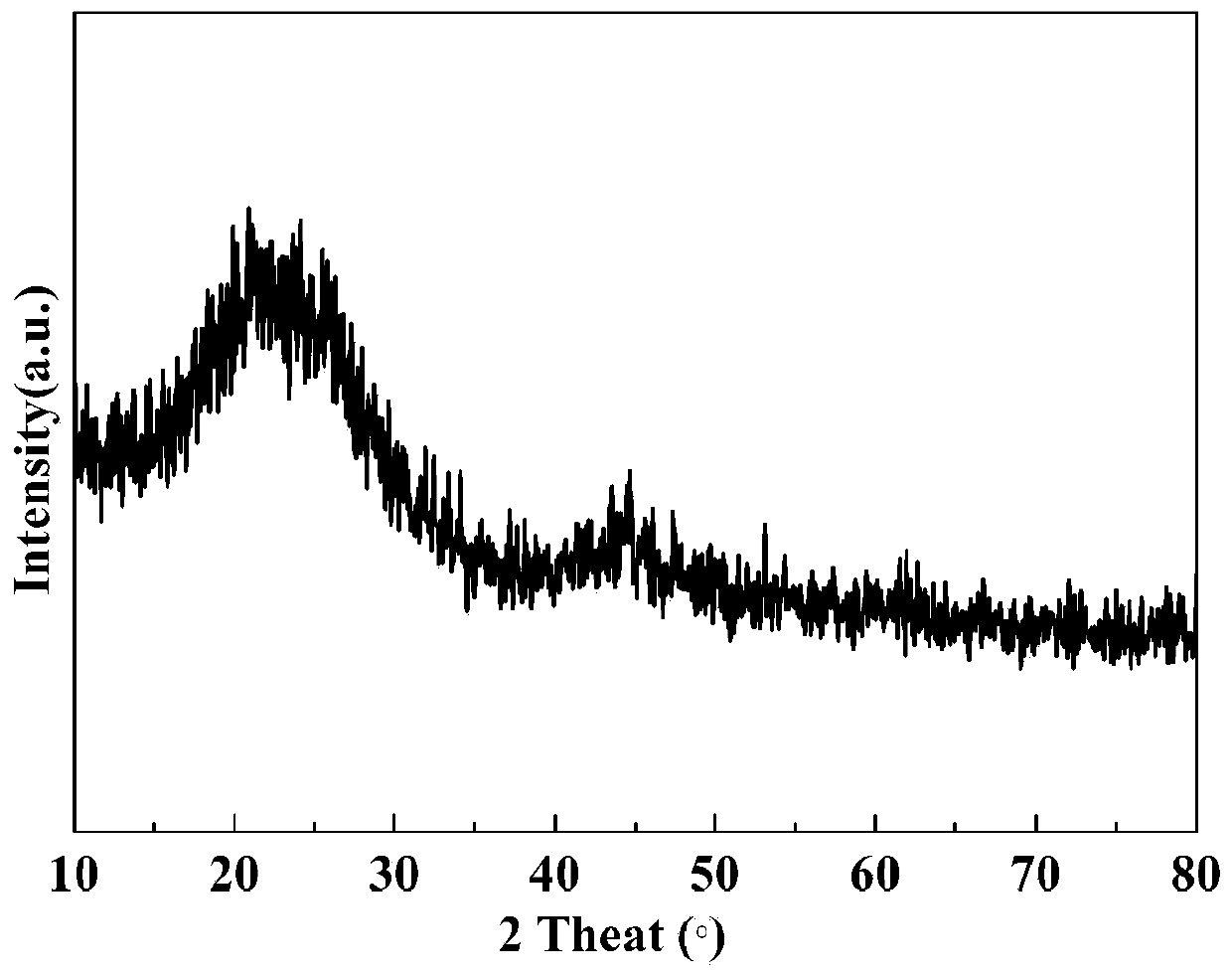

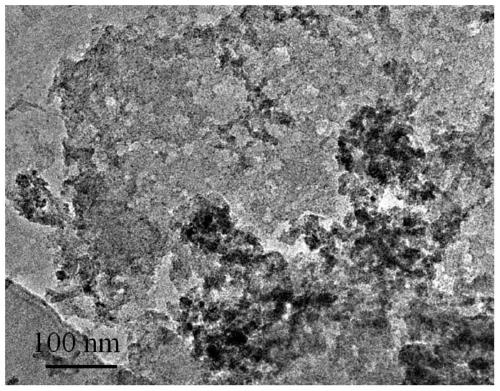

[0034] 4) The product of step 3) was placed in a ceramic crucible, heated from room temperature to 800° C. for 2 hours at a rate of 5° C. / min under the pro...

Embodiment 2

[0041] 1) Dissolve sucrose in a mixed solvent of acetone and deionized water with a volume ratio of 1:1, and stir thoroughly to obtain a 0.04mol / L precursor solution;

[0042] 2) Take a nickel foam self-support body with a length of 40mm, a width of 25mm, and a thickness of 1.0mm, and then ultrasonically clean it with deionized water, acetone, hydrochloric acid with a concentration of 1mol / L, and ethanol for 40min, 60min, 5min, and 50min, and then vacuum-dry it at 80°C 12h, then add the dried nickel foam self-supporting body and precursor solution into a polytetrafluoroethylene-lined reactor, and react hydrothermally at 160°C for 24h;

[0043] 3) After the reaction, cool down to room temperature naturally, wash the product 6 times with deionized water and absolute ethanol, and dry it in a vacuum oven at 120°C for 12 hours;

[0044] 4) Place the product of step 3) in a ceramic crucible, heat it from room temperature to 700° C. for 2 hours at a rate of 7° C. / min under the protec...

Embodiment 3

[0046] 1) Dissolve sucrose in a mixed solvent of acetone and deionized water with a volume ratio of 1:3, and stir thoroughly to obtain a 0.08mol / L precursor solution;

[0047] 2) Take a nickel foam self-support body with a length of 40 mm, a width of 25 mm, and a thickness of 1.0 mm, and then ultrasonically clean it with deionized water, acetone, hydrochloric acid with a concentration of 3 mol / L, and ethanol for 50 min, 30 min, 10 min, and 60 min, and then vacuum-dry it at 80°C 12h, and then add the dried nickel foam self-supporting body and precursor solution into a polytetrafluoroethylene-lined reactor, and conduct a hydrothermal reaction at 190°C for 20h;

[0048] 3) After the reaction, cool down to room temperature naturally, wash the product 6 times with deionized water and acetone, and dry it in a vacuum oven at 100°C for 18 hours;

[0049] 4) Place the product of step 3) in a ceramic crucible, heat it from room temperature to 900°C at a rate of 10°C / min under the protec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com