High-strength toughness aluminum brass alloy and manufacturing method thereof

A high-strength toughness and manufacturing method technology, applied in the field of high-strength toughness aluminum-brass alloy and its manufacturing, can solve the problems of poor toughness, excess strength, hardness, and insufficient toughness, etc., and achieve high elongation, high toughness, and durability. good grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

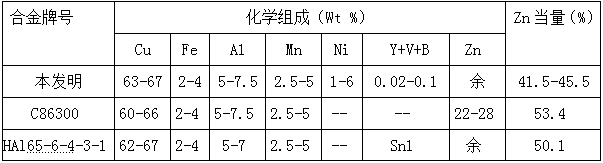

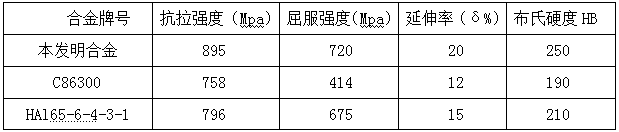

[0024] Concrete mass percentage composition of alloy composition of the present invention:

[0025] Copper 66%

[0026] Iron 3%

[0027] Aluminum 6%

[0028] Manganese 3%

[0029] Nickel 6%

[0030] Yttrium 0.025% + Vanadium 0.03% + Boron 0.025%, the balance is zinc and unavoidable impurities.

[0031] The specific manufacturing method of the smelting high-strength toughness aluminum brass alloy provided by the invention comprises the following steps:

[0032] The high-strength toughness aluminum-brass alloy provided by the invention is batched according to the mass percentage. The raw materials are electrolytic industrial pure copper, aluminum, manganese, nickel and iron (select degreasing and rust-free iron wire or iron nails), and copper-boron, copper- Yttrium, aluminum-vanadium and other master alloys, by adjusting the amount of the master alloy added, the total content of the three metal elements of yttrium, vanadium and boron in the high-strength and toughness alumi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com