Material-saving cutting mechanism of strapping machine

A technology of cutting mechanism and strapping machine, which is applied to the parts of strapping machinery, strapping materials, strapping objects, etc., to achieve the effect of improving toughness and not being easy to tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

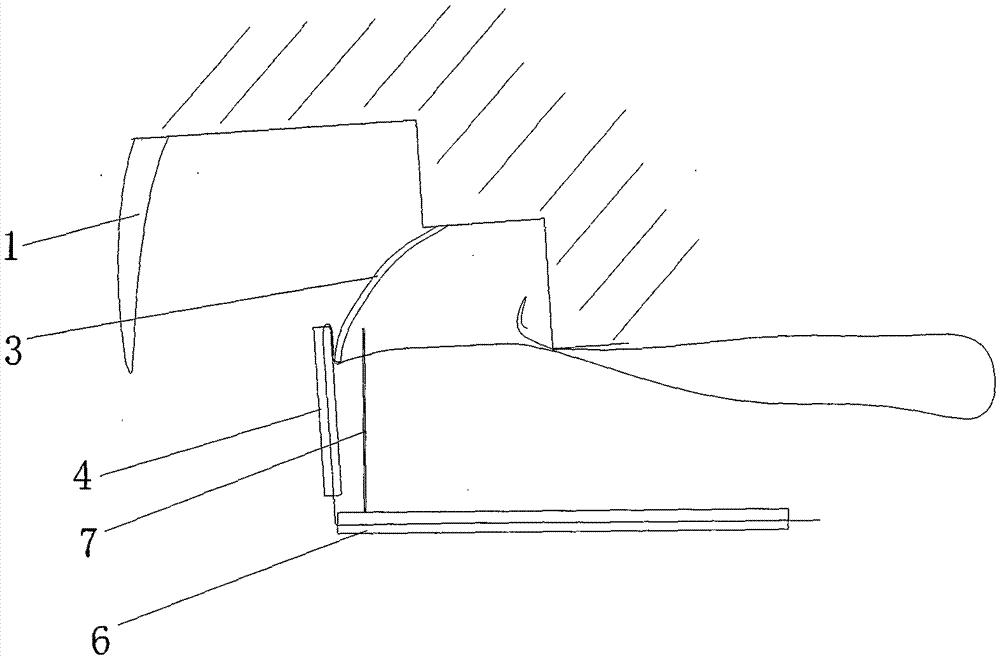

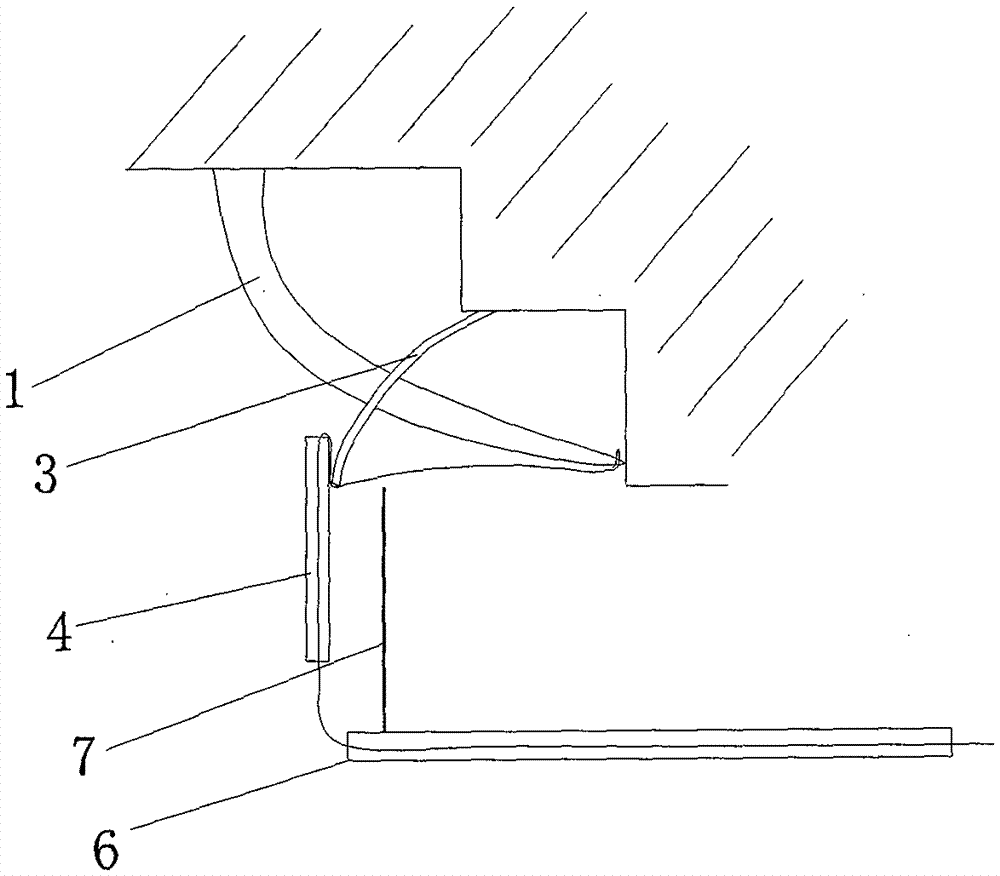

[0020] figure 1 , 2 , 3, the present invention includes handle 6, tongue drag 9 and pincer bar 11, and the three are all hinged, and the three are positioned at a certain angle, and a spring return mechanism is provided between the two, whenever the three are After pressing and then losing force, it can quickly return to the original angle.

[0021] The tongue drag 9 is arranged between the handle 6 and the pincer rod 11, and the tongue drag 9 and the pincer rod 11 form a jaw, and the tongue drag 9 is provided with a binding belt slot 4, a knife slot 12, and a needle magazine in sequence from the front end to the rear. 8, set the belt groove 4 as a cross groove.

[0022] The end of the pliers rod 11 is divided into fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com