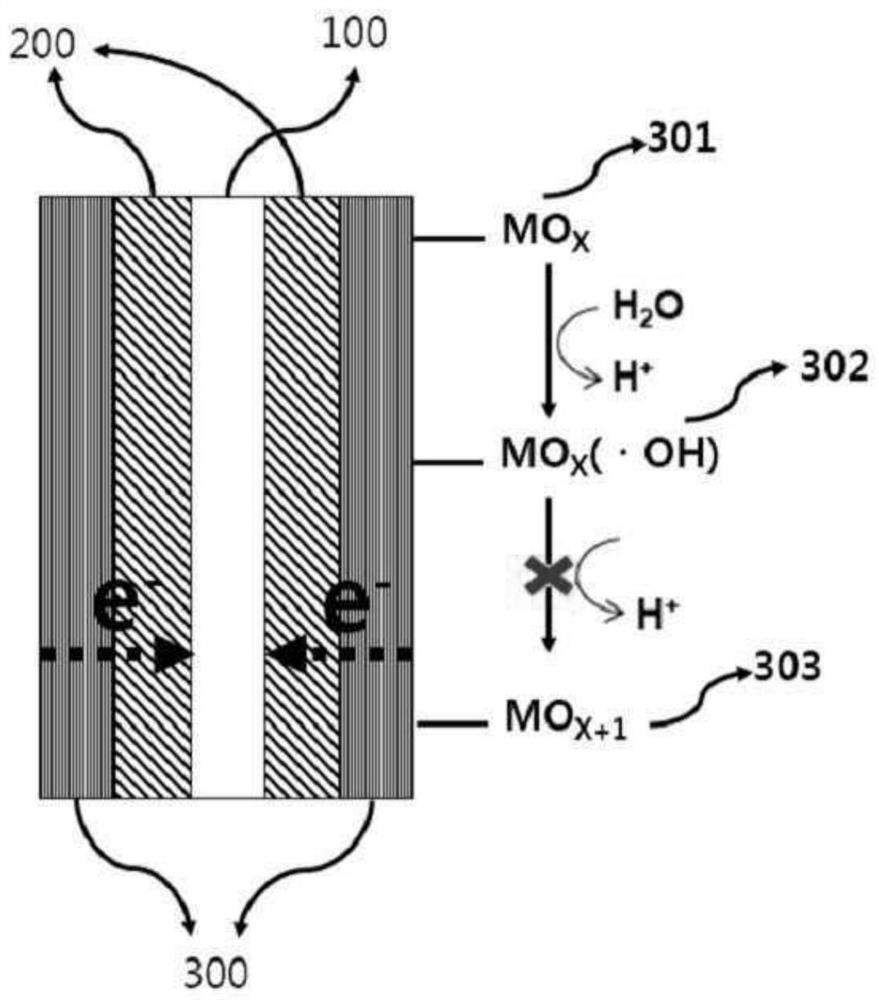

Oxidation electrode, manufacturing method thereof, and electrolysis device comprising same

A manufacturing method and electrode technology, applied in chemical instruments and methods, water/sludge/sewage treatment, water/sewage treatment, etc., can solve problems such as decreased stability, increase decomposition efficiency, prevent dissolution, and minimize electrical resistance the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

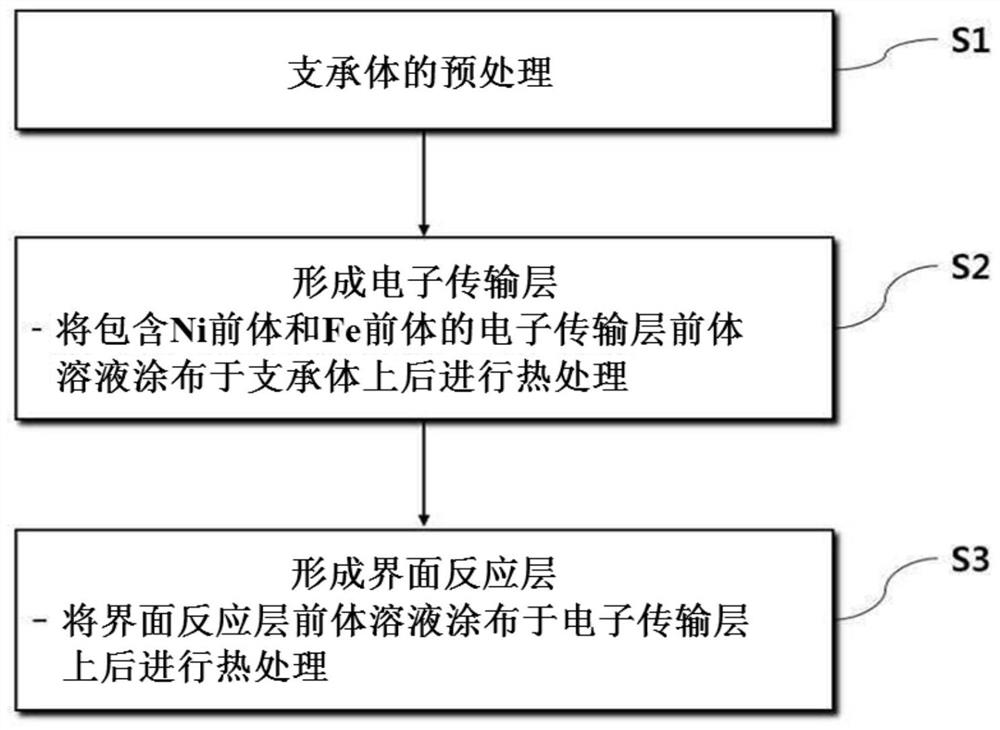

[0134] Pretreatment of supports

[0135] A Ti support in the form of a flat plate having a size of 10 cm×10 cm (length×width) and a thickness of 1 mm was prepared. Grind the above-mentioned support with sandpaper until the gloss of the surface disappears, and heat-treat at about 80° C. in an oxalic acid solution in which 10 g of oxalic acid is dissolved per 100 mL of the solution, and then use diluted acetone and distilled water. Washing to pretreat the Ti support.

[0136] electron transport layer

[0137] Ni(NO 3 ) 2 and Fe(NO 3 ) 2 After dissolving in ethanol at a molar ratio of about 1:2, an electron transport layer precursor solution adjusted so that the total metal ion concentration was about 250 mM was prepared.

[0138] The above-mentioned electron transport layer precursor solution is coated on the pretreated Ti support body by dip coating method, and a total of 6 times of heat treatment at about 425 ° C for about 10 minutes are carried out to form an electr...

reference example 1

[0143] H 2 IrCl 6 and TaCl 5 After dissolving in isopropanol at a molar ratio of 7:3, an electron-transporting layer precursor solution adjusted so that the concentration of the total metal ions becomes about 150 mM was prepared, and the same method as in Example 1 was produced. oxidation electrode.

experiment example

[0156] [Experimental example]-The amount of current generation, the amount of active chlorine cluster generation, and the battery voltage of the oxidation electrode were compared. The amount of current generated by the oxidation electrode.

[0157] Specifically, a reduction electrode made of stainless steel having the same size (10 cm×10 cm) as the above-mentioned oxidation electrode was prepared. Arrange in parallel so that the distance between the oxidation electrode and the reduction electrode is about 5 mm, and soak in 100 mL of 50 mM electrolyte (NaCl), and make the 8 cm of each electrode 2 contact with electrolyte. Furthermore, an Ag / AgCl reference electrode is disposed on one side of the oxidation electrode.

[0158] Each of the above oxidation electrodes and reduction electrodes was connected to a potentiostat (Potentiostat, Bio-Logic, SP-50).

[0159] Under the voltage condition of 0.8V~2.2V relative to the Ag / AgCl reference electrode, the oxidation electrodes invo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com