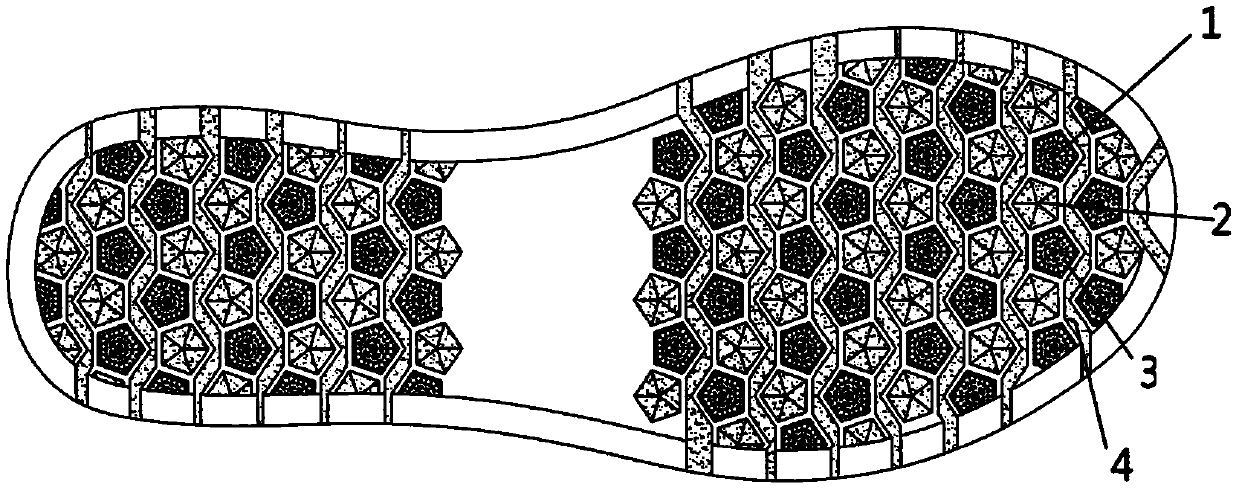

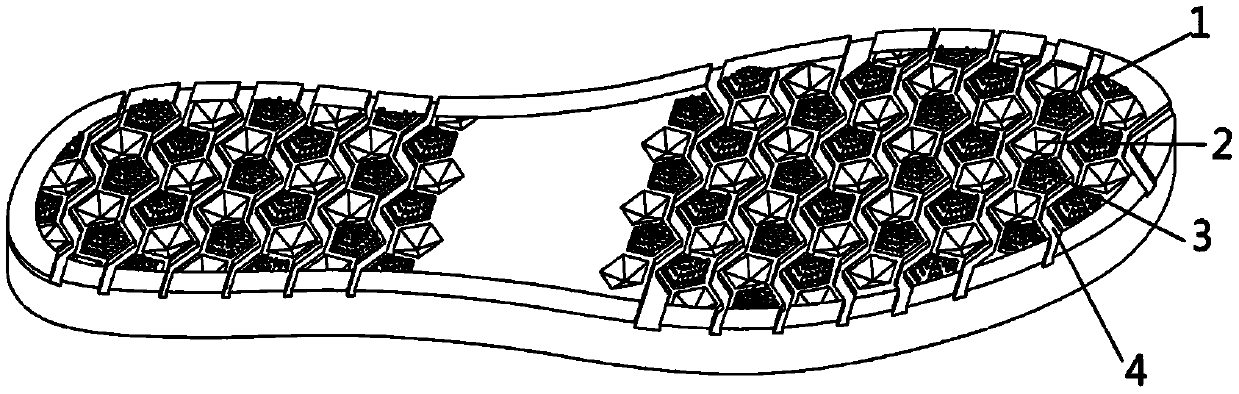

Anti-slip sole

A non-slip and outsole technology, which is applied in the direction of shoe soles, footwear, clothing, etc., can solve the problems of human injury, insufficient anti-skid performance, easy yellowing of soles, and frosting, so as to weaken stress, improve anti-skid effect, and improve anti-slip The effect of wet slip performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Neoprene 68 grams, epoxidized natural rubber 32 grams, ethylene-vinyl acetate copolymer 8 grams, thiodipropionate diester 5 grams, carbon black 5 grams, plasticizer 8 grams, silane coupling agent 1.5 gram, hemp fiber 7 grams, zinc oxide 2 grams, PEG-4000 2 grams, polyethylene wax 1 gram, vulcanization accelerator 3 grams, zinc carbonate 3 grams, stearic acid 1 gram, antioxidant SP 1 gram.

Embodiment 2

[0066] Neoprene 85 grams, epoxidized natural rubber 38 grams, ethylene-vinyl acetate copolymer 10 grams, thiodipropionate diester 10 grams, carbon black 8 grams, plasticizer 10 grams, silane coupling agent 2 gram, hemp fiber 8 grams, zinc oxide 3 grams, PEG-4000 3 grams, polyethylene wax 2 grams, vulcanization accelerator 5 grams, zinc carbonate 5 grams, stearic acid 2 grams, antioxidant SP 2 grams.

Embodiment 3

[0068] Neoprene 72 grams, epoxidized natural rubber 33 grams, ethylene-vinyl acetate copolymer 8 grams, thiodipropionate diester 6 grams, carbon black 6 grams, plasticizer 8 grams, silane coupling agent 1.5 gram, hemp fiber 7 grams, zinc oxide 2 grams, PEG-4000 2 grams, polyethylene wax 1 gram, vulcanization accelerator 3 grams, zinc carbonate 3 grams, stearic acid 1 gram, antioxidant SP 1 gram.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com