Preparation method of high water, oxygen and high temperature-resistant cell

A technology of high temperature resistance and water resistance, applied in non-aqueous electrolyte batteries, electrolyte battery manufacturing, circuits, etc., to achieve the effect of improving service life and safety performance, reducing control requirements, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1 Preparation of Al by Coating and Adhesive Method 2 o 3 / PET / CPP insulation film

[0029] (1) Apply glue evenly on the surface of the PET film with a gravure coater to realize the adhesion between the CPP film and the PET film to make a PET / CPP film, wherein the thickness of the CPP film is 60 μm, and the thickness of the PET film is 10 μm;

[0030] (2) Al 2 o 3 Powder, styrene-butadiene rubber binder, and water are mixed according to the mass percentage of 49:0.5:50, and then a uniform and stable Al 2 o 3 slurry, using a gravure coater to coat Al 2 o 3 The slurry is uniformly coated on the surface of the PET layer of the PET / CPP film, Al 2 o 3 The thickness of the coating is 3 μm, and the water-blocking, oxygen-blocking and high-temperature resistant Al 2 o 3 / PET / CPP insulation film.

Embodiment 2

[0031] Example 2 Preparation of Al by Melt Extrusion and Thermal Bonding 2 o 3 / PET / CPP insulation film

[0032] (1) Use hot extrusion equipment to melt CPP particles at a high temperature of 180°C, and process them into a film with a thickness of 70 μm through an extrusion touch head. The extrusion width of the CPP film is the same as that of the PET film; the extruded CPP film and the PET film The compounding of the two is realized by a heat recovery machine, the thickness of the PET film is 20 μm, and the heat recovery temperature is controlled at 150 ° C to prepare a PET / CPP film;

[0033] (2) Al 2 o3 Powder, polyacrylic acid binder, and water are mixed according to the mass percentage of 49:0.5:50, and then a uniform and stable Al is prepared by a high-speed disperser 2 o 3 slurry, using a gravure coater to coat Al 2 o 3 The slurry is uniformly coated on the surface of the PET layer of the PET / CPP film, Al 2 o 3 The thickness of the coating is 2 μm, and Al is prep...

Embodiment 3

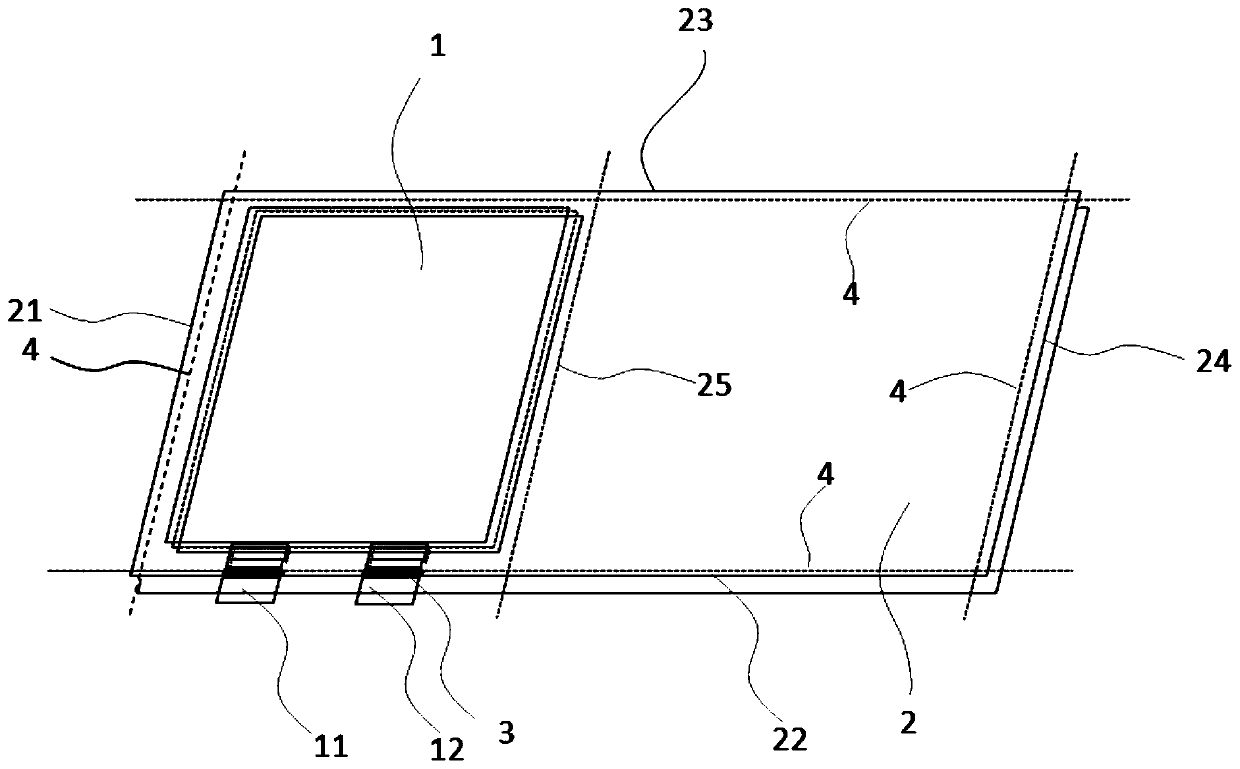

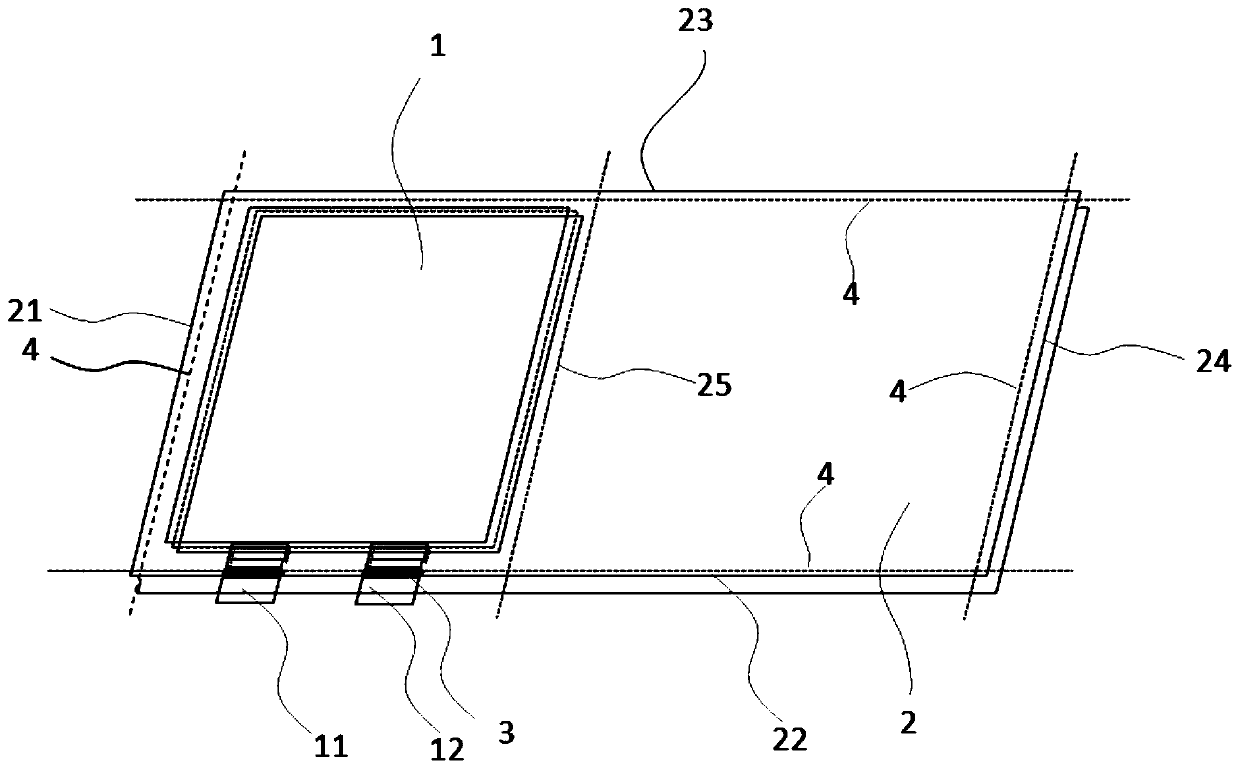

[0034] Example 3 Preparation of high-resistance water-resistance oxygen-resistance high-temperature resistant electric core

[0035] (1) Coat the viscous slurry containing the positive active material on the aluminum foil and dry it, and make a laser sheet to make the positive pole piece, and use the aluminum foil as the positive tab; coat the viscous slurry containing the negative active material on the copper Foil, drying, and laser production to make negative pole pieces, using copper foil as negative pole lugs; making positive pole pieces, diaphragms, and negative pole pieces into roll core 1 by lamination; figure 1 As shown, the single positive pole lug and negative pole lug in the winding core are ultrasonically welded on the positive pole connecting piece 11 and the negative pole connecting piece 12 respectively, and the surfaces of the positive pole connecting piece 11 and the negative pole connecting piece 12 are coated with PP glue 3 The distance between the coating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com