Self-supporting composite film for liquid-phase zinc ion battery and preparation method thereof

A zinc-ion battery and composite film technology, applied in the field of electrochemistry, can solve the problems of reducing battery cycle and rate performance, reducing battery energy density, increasing electrode preparation cost, etc., and achieving improved structural stability, stable cycle performance, and good industrialization. The effect of applying potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

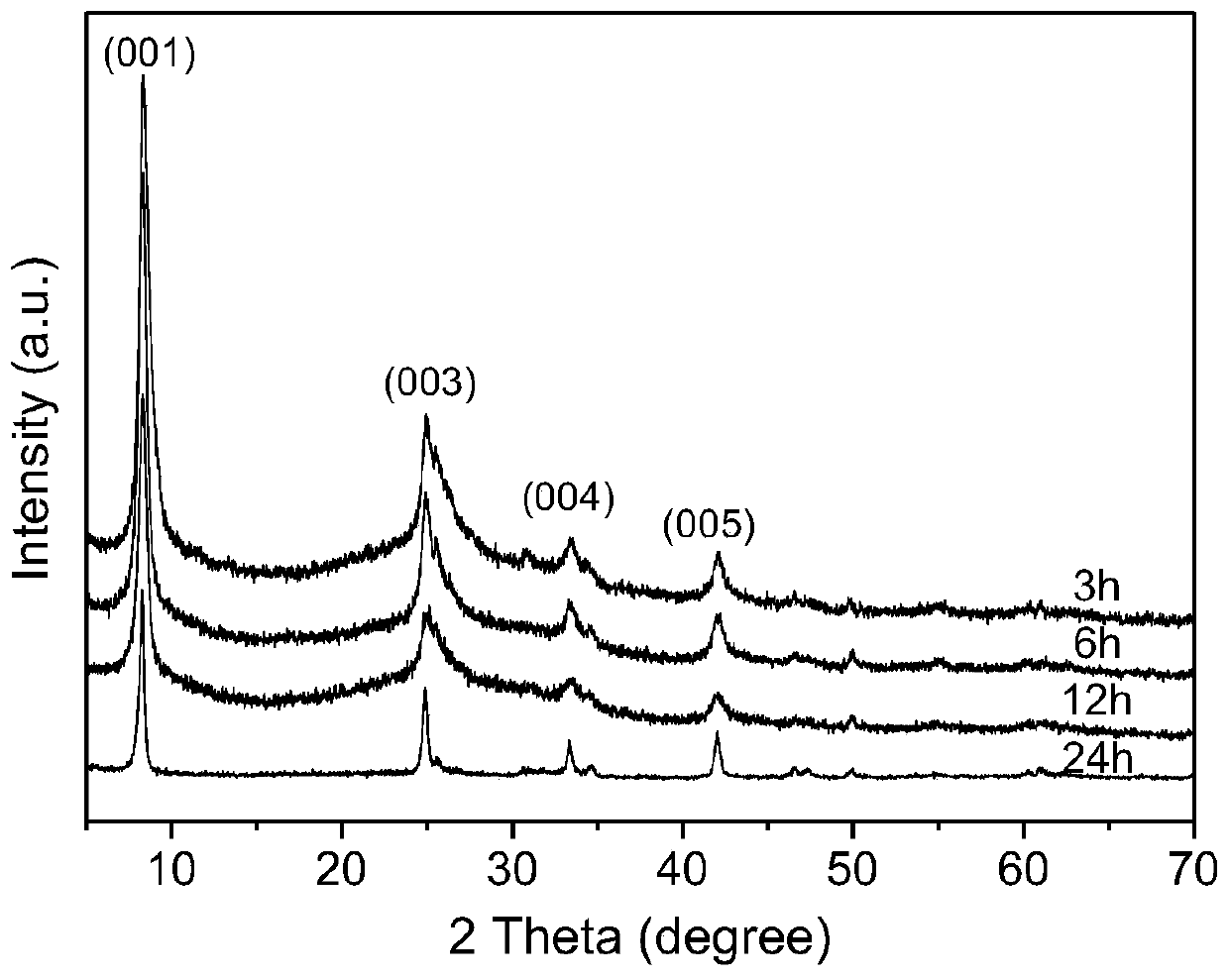

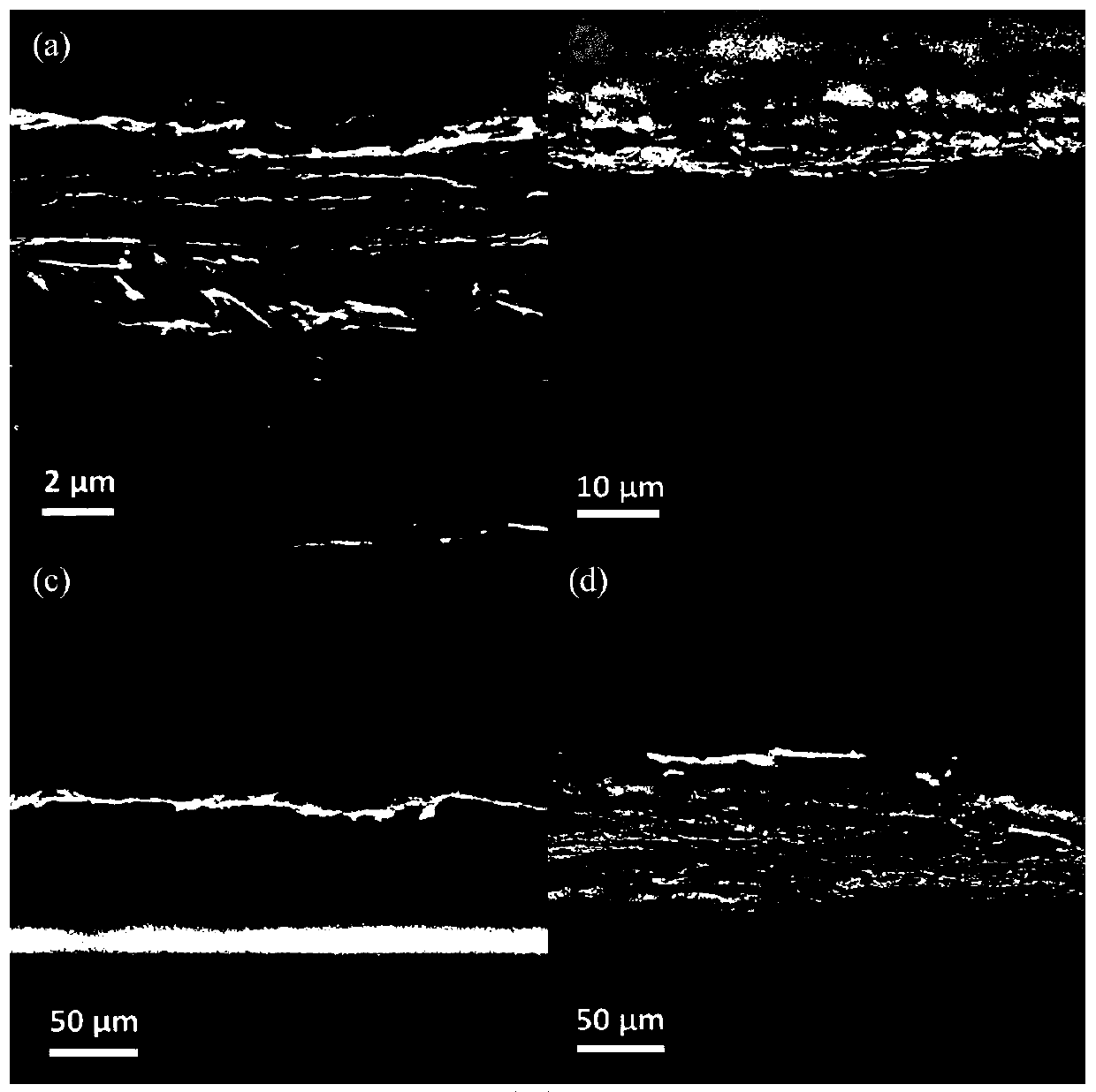

[0041] This embodiment provides a metal ion pre-embedded vanadium pentoxide nanobelt / carbon nanotube self-supporting composite film that can be directly used as the positive electrode of a zinc ion battery. Its preparation method comprises the following steps:

[0042] In the first step, at room temperature, add 0.182g of commercial vanadium pentoxide and 0.284g of sodium sulfate into 30mL of deionized water, sonicate in a water bath for 30min, stir magnetically for 30min, transfer to a hydrothermal kettle, keep at 180°C for 24h, and dissolve the product Washed three times with deionized water, and dried in vacuum at 80°C for 24 hours to obtain the metal ion pre-intercalated vanadyl precursor.

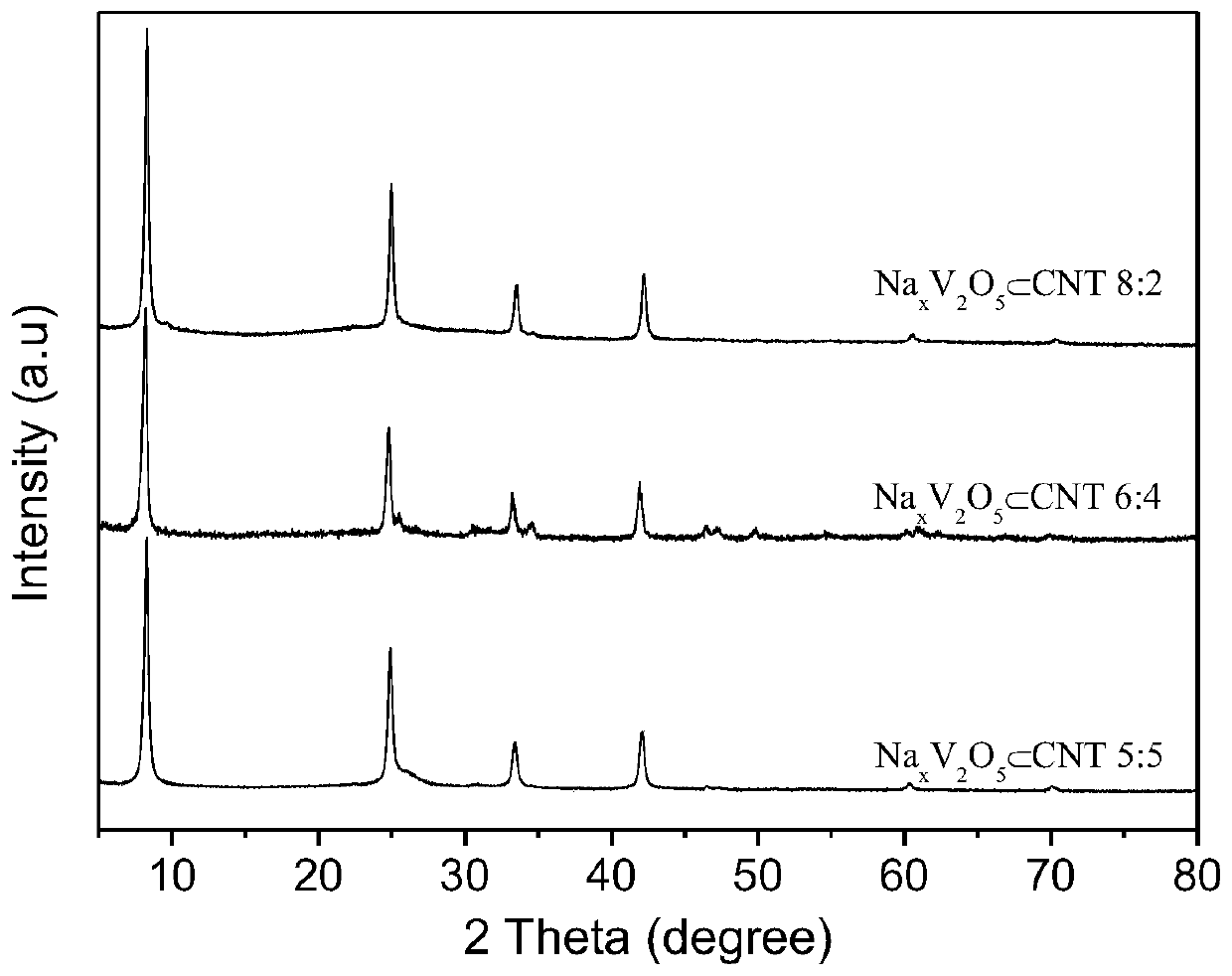

[0043] In the second step, 60 mg of the metal ion pre-embedded vanadyl precursor was added into the deionized aqueous solution, the cells were pulverized by ultrasound for 30 minutes, and magnetically stirred for 30 minutes. The resulting dispersion was dropped dropwise into 40 mg of ...

Embodiment 2

[0046] This embodiment provides a metal ion pre-embedded vanadium pentoxide nanobelt / carbon nanotube self-supporting composite film that can be directly used as the positive electrode of a zinc ion battery. Its preparation method comprises the following steps:

[0047] In the first step, at room temperature, add 0.182g of commercial vanadium pentoxide and 0.284g of sodium sulfate into 30mL of deionized water, sonicate in a water bath for 30min, stir magnetically for 30min, transfer to a hydrothermal kettle, keep at 180°C for 24h, and dissolve the product Wash with deionized water for several times, and vacuum-dry at 80°C for 24 hours to obtain a vanadium oxide precursor pre-intercalated with metal ions.

[0048] In the second step, 60 mg of the metal ion pre-embedded vanadyl precursor was added into the deionized aqueous solution, the cells were pulverized by ultrasound for 30 minutes, and magnetically stirred for 30 minutes. The resulting dispersion was dropped dropwise into...

Embodiment 3

[0051] This embodiment provides a metal ion pre-embedded vanadium pentoxide nanobelt / carbon nanotube self-supporting composite film that can be directly used as the positive electrode of a zinc ion battery. Its preparation method comprises the following steps:

[0052] In the first step, at room temperature, add 0.182g of commercial vanadium pentoxide and 0.284g of sodium sulfate into 30mL of deionized water, sonicate in a water bath for 30min, stir magnetically for 30min, transfer to a hydrothermal kettle, keep at 180°C for 24h, and dissolve the product Wash with deionized water for several times, and vacuum-dry at 80°C for 12 hours to obtain a vanadium oxide precursor pre-intercalated with metal ions.

[0053] In the second step, 60 mg of the metal ion pre-embedded vanadyl precursor was added into the deionized aqueous solution, the cells were pulverized by ultrasound for 30 minutes, and magnetically stirred for 30 minutes. The resulting dispersion was dropped dropwise into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com