Intermittent rib inner cooling structure used for gas turbine blade

A technology of turbine blades and gas turbines, which is applied in the direction of blade support components, mechanical equipment, engine components, etc., can solve the problem of air volume reduction, etc., and achieve the effects of reducing pressure loss, enhancing heat transfer, and enhancing heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in more detail below in conjunction with accompanying drawing example:

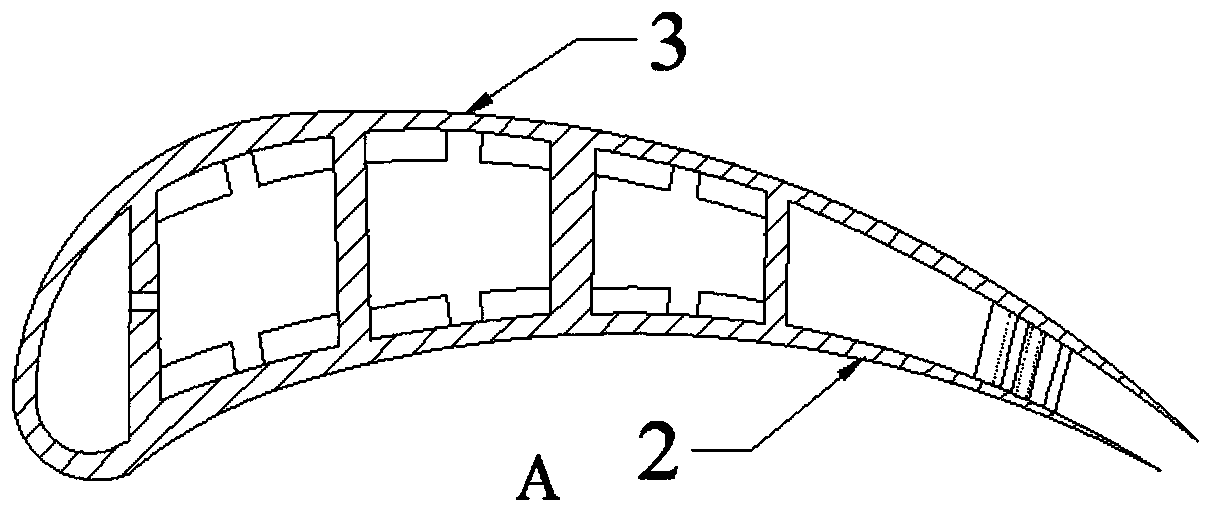

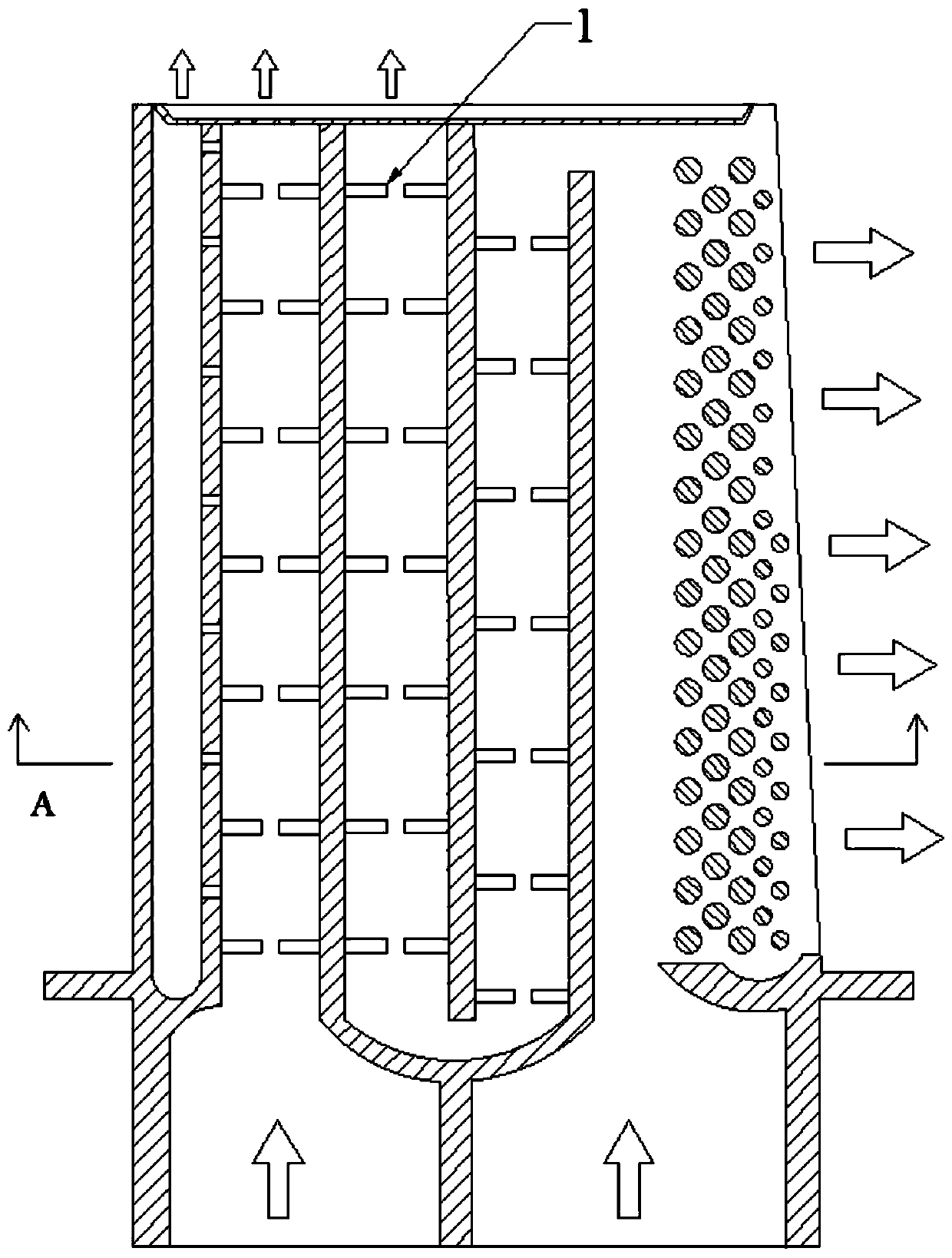

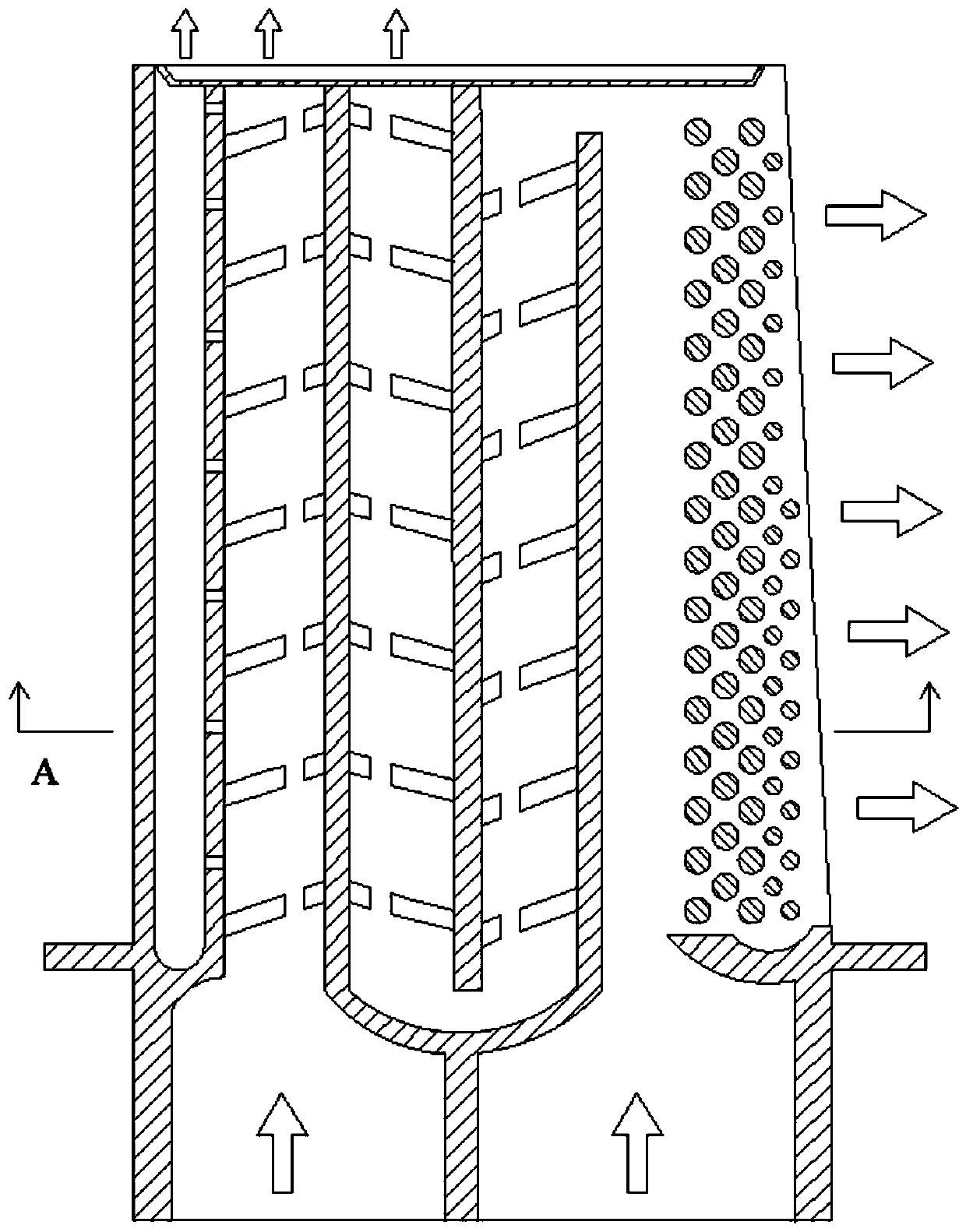

[0017] combine Figure 1-3 , the present invention is an internal cooling structure of discontinuous ribs for gas turbine blades, comprising an upper wall 3 , a lower wall 2 and discontinuous ribs 1 . The upper wall 1 is the suction surface of the blade, and the lower wall 2 is the pressure surface of the blade. The discontinuous rib 1 is located in the serpentine cooling channel of the turbine blade, and two rows of discontinuous ribs 1 are respectively located inside the upper wall 3 and the lower wall 2 of the blade. The discontinuous rib 1 is a straight rib, which can be perpendicular to the wall of the serpentine cooling channel, or can be inclined 30° to 60° relative to it. The interrupted rib 1 is equivalent to opening a fracture in a traditional complete rib. The width of the fracture is equal to the height of the rib 1, and the direction of the opening ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com