UHPC (ultrahighperformanceconcrete) box type steel tube concrete stiff skeleton column structure and construction method thereof

A technology of rigid skeleton and box-shaped steel pipes, which is applied in the direction of erecting/assembling bridges, bridge parts, bridge materials, etc., can solve the problems of poor self-compactness, increase construction difficulty, increase the space occupied by pier columns, etc., and achieve excellent wear resistance Performance and anti-knock performance, improve anti-wind and sand ability, prolong the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific examples are given in conjunction with the drawings, and detailed descriptions are made as follows.

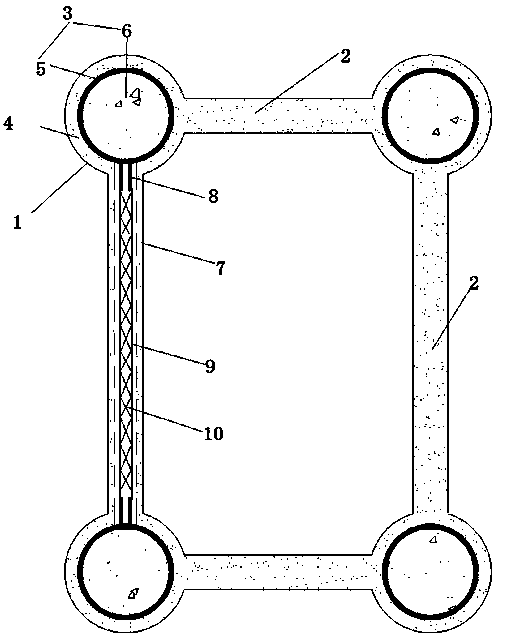

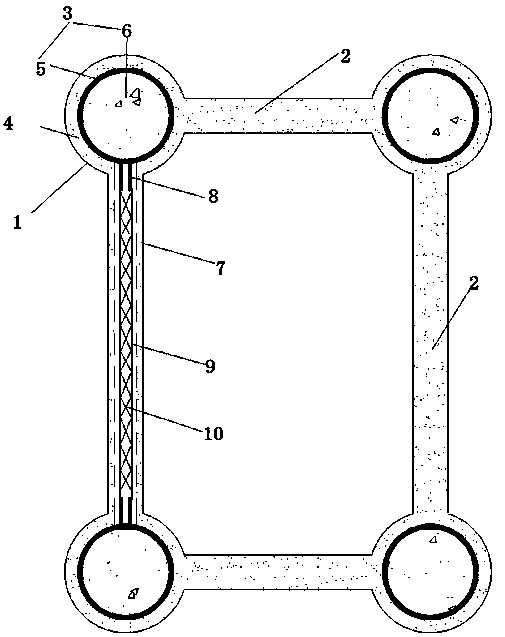

[0021] Such as figure 1 As shown, a UHPC box-type concrete-filled steel tube rigid skeleton column structure includes four equal-length support columns 1, which are connected by reinforced UHPC plates 2 to form a square structure with support columns located at four corners. The column and the reinforced UHPC board are arranged in a full length; the support column is composed of a steel tube concrete column 3 and an outer UHPC layer 4 wrapping the steel tube concrete column. The steel tube concrete column includes a steel tube 5 and an in-tube concrete 6 filled in the steel tube; The reinforced UHPC board includes a square UHPC board 7 located between two adjacent support columns. A positioning block 8 is fixed in the square UHPC board on the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com