Super-thick high-hardenability HB500-grade wear-resistant steel plate and manufacturing method thereof

A high-hardenability, wear-resistant steel plate technology, which is applied in the field of high-strength wear-resistant steel plate preparation, can solve the problems of unfavorable equipment durability, long-term use, short mechanical service life, neglect of steel plate uniformity, etc., and achieve good low-temperature impact toughness, Guaranteed performance uniformity and excellent hardenability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

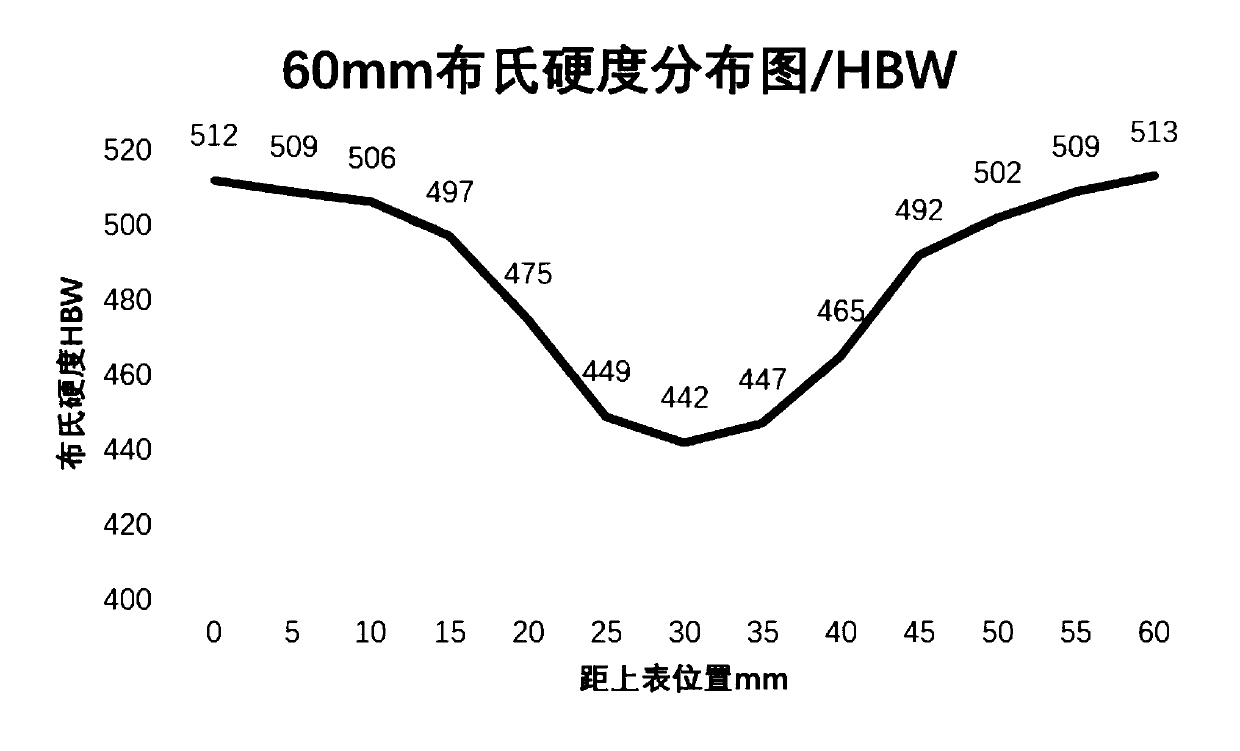

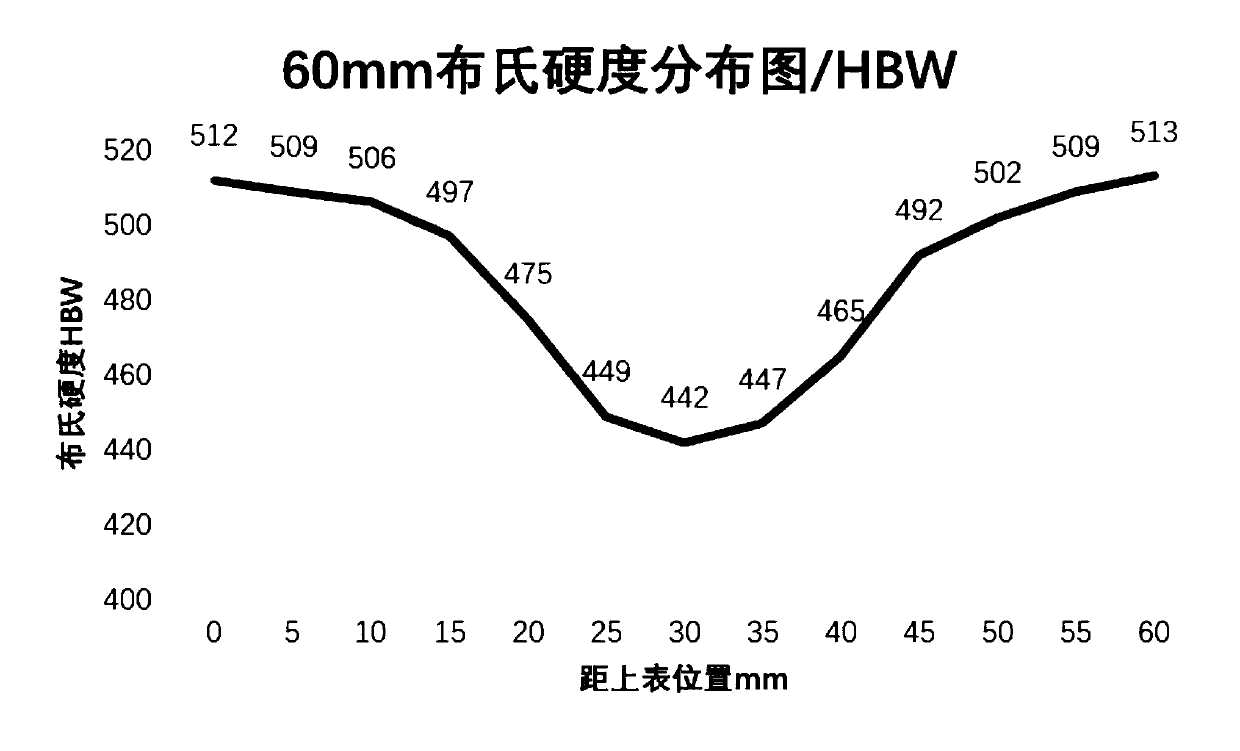

Embodiment 1

[0045] An extra-thick and high-hardenability HB500 wear-resistant steel plate. The thickness of the steel plate is 60 mm. The components contained in the steel plate and their weight percentages are as follows: C: 0.30%, Si: 0.26%, Mn: 0.85%, P: 0.008%, S: 0.003%, Alt: 0.035%, Ni: 0.22%, Cr: 0.85, Mo: 0.28%, Ti: 0.018%, N: 0.0030%, H: 0.00011%, and the rest are Fe and trace impurities.

[0046] The above-mentioned extra-thick and high-hardenability HB500 wear-resistant steel plate with a thickness of 60mm is manufactured as follows:

[0047] (1) Smelting: The cross-sectional size of molten iron is 300× after KR pretreatment, 120-ton top-bottom combined blowing converter smelting, 120-ton LF ladle furnace refining, 120-ton RH vacuum degassing refining, and slab continuous casting machine. 1800mm continuous casting slab;

[0048] (2) Slow cooling of continuous casting slabs: After the continuous casting slabs come off the assembly line, they are slowly cooled in the heat preser...

Embodiment 2

[0055] An extra-thick and high-hardenability HB500 wear-resistant steel plate. The thickness of the steel plate is 70mm. The components contained in the steel plate and their weight percentages are as follows: C: 0.31%, Si: 0.24%, Mn: 0.77%, P: 0.006%, S: 0.003%, Alt: 0.037%, Ni: 0.23%, Cr: 0.92, Mo: 0.26%, Ti: 0.019%, N: 0.0033%, H: 0.00014%, and the rest are Fe and trace impurities.

[0056] The production and preparation process of the extra-thick and high-hardenability HB500 wear-resistant steel plate in this example and the thickness of the continuous casting slab are the same as in Example 1, the difference is that:

[0057] The thickness of the steel plate is 70mm; in step (4), the starting rolling temperature of the austenite non-recrystallized zone is 980°C, and the starting rolling thickness of the austenite non-recrystallized zone is 160mm; the off-line quenching in step (5) The heat treatment process is as follows: the steel plate is heated to 905°C for 140 minutes...

Embodiment 3

[0060] An extra-thick and high-hardenability HB500 wear-resistant steel plate. The thickness of the steel plate is 80 mm. The components contained in the steel plate and their weight percentages are as follows: C: 0.29%, Si: 0.26%, Mn: 0.79%, P: 0.005%, S: 0.003%, Alt: 0.031%, Ni: 0.26%, Cr: 0.84, Mo: 0.24%, Ti: 0.023%, N: 0.0023%, H: 0.00011%, and the rest are Fe and trace impurities.

[0061] The production and preparation process of the high-hardenability HB500 wear-resistant steel plate of this embodiment and the thickness of the continuous casting slab are the same as those of Embodiment 1, the difference is that:

[0062] The thickness of the steel plate is 80 mm; in step (4), the starting rolling temperature of the austenite non-recrystallized zone is 990 ° C, and the starting rolling thickness of the austenite non-recrystallized zone is 170 mm; the off-line quenching in step (5) Heat treatment: the steel plate is heated to 900°C for 160 minutes, rapidly quenched to roo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Core hardness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com