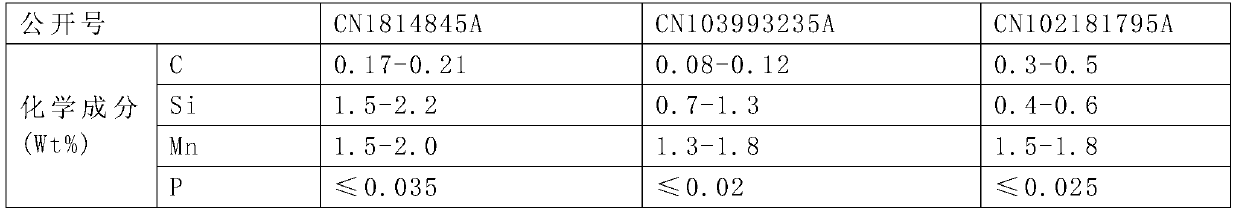

Bulletproof steel plate for armor and manufacturing method thereof

A manufacturing method and technology for steel plates, which are applied to bulletproof steel plates for armor and their manufacturing fields, can solve problems such as low elongation, achieve uniform performance, ensure uniform performance, and eliminate residual internal stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 5

[0060] The difference between Example 5 and Example 1 is that the weight percentage of Cr is 0.7%, and the percentages of other components are the same as in Example 5, and then the steel plate is prepared by using the preparation method and process parameters of the steel plate provided in Example 5.

Embodiment 6

[0062] The difference between Example 6 and Example 1 is that the component Co is removed, and the percentages of other components are the same as in Example 5, and then the steel plate is prepared by using the preparation method and process parameters of the steel plate provided in Example 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com