7-series aluminum alloy profile used for civil aircraft first rib and preparation method thereof

An aluminum alloy profile, No. 1 technology, applied in the field of 7-series aluminum alloy profiles for the No. 1 rib of civil aircraft and its preparation, can solve the difficulty in the shape and position tolerance of the profile, and the difference in the size, structure and performance of the head end and tail end of the profile , It is difficult to ensure the uniformity of profile deformation, etc., to achieve the effect of ensuring uniformity of performance, reducing temperature and performance differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

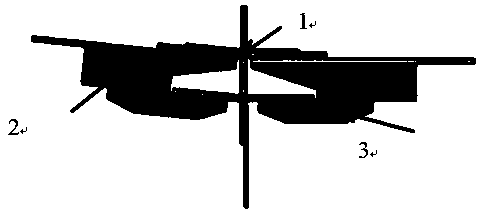

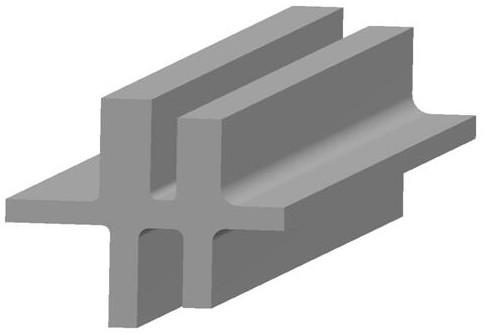

Image

Examples

Embodiment 1

[0045] Step 1: Use semi-continuous casting to produce large-scale 7-series ingots with all indicators meeting the technical specifications, and perform homogenization annealing. Chemical analysis of the ingot shows that the Si content is 0.05%, the Fe content is 0.08%, the Cu content is 2.25%, the Mg content is 2.15%, the Mn content is 0.02%, the Cr content is 0.0084%, the Zn content is 8.21%, and the Ti content is 0.035%. %, Zr content is 0.103%, and the balance is aluminum;

[0046] Step 2: Heat and heat-preserve the mold with a box-type mold heating furnace to ensure that the core of the mold is warm and the mold temperature is heated to 390°C;

[0047] Step 3: The set temperature of the extrusion barrel is 400°C, and the extrusion can only be carried out after the temperature reaches. ℃ / m, put the heated ingot into the extrusion cylinder, put the ingot head into the left and right double-hole molds, and perform reverse extrusion. The extrusion axis speed of reverse extrus...

Embodiment 2

[0051] Step 1: Use semi-continuous casting to produce large-scale 7-series ingots with all indicators meeting the technical specifications, and perform homogenization annealing. Chemical analysis of the ingot shows that the content of Si is 0.06%, the content of Fe is 0.08%, the content of Cu is 2.15%, the content of Mg is 2.19%, the content of Mn is 0.02%, the content of Cr is 0.0081%, the content of Zn is 7.98%, and the content of Ti is 0.034 %, Zr content is 0.098%, and the balance is aluminum;

[0052] Step 2: Heat and heat-preserve the mold with a box-type mold heating furnace to ensure that the core of the mold is warm and the mold temperature is heated to 410°C;

[0053] Step 3: The temperature of the extrusion barrel is set at 420°C, and the extrusion can only be carried out after the temperature reaches the temperature. ℃ / m, put the heated ingot into the extrusion barrel, put the ingot head into the left and right double-hole molds, and perform reverse extrusion. The...

Embodiment 3

[0057] Step 1: Use semi-continuous casting to produce large-scale 7-series ingots with all indicators meeting the technical specifications, and perform homogenization annealing. Chemical analysis of the ingot shows that the Si content is 0.05%, the Fe content is 0.09%, the Cu content is 2.13%, the Mg content is 2.12%, the Mn content is 0.01%, the Cr content is 0.0071%, the Zn content is 8.14%, and the Ti content is 0.029% %, Zr content is 0.114%, and the balance is aluminum;

[0058] Step 2: Heat and heat-preserve the mold with a box-type mold heating furnace to ensure that the core of the mold is warm and the mold temperature is heated to 400°C;

[0059]Step 3: The set temperature of the extrusion cylinder is 410°C, and the extrusion can only be carried out after the temperature reaches. ℃ / m, put the heated ingot into the extrusion cylinder, put the ingot head into the left and right double-hole molds, and perform reverse extrusion. The extrusion axis speed of reverse extrus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com