Method and device for recycling liquid nitrogen washing exhaust gas

A liquid nitrogen washing and recycling technology, which is applied in chemical instruments and methods, carbon monoxide, separation methods, etc., can solve the problems of inability to realize the resource utilization of liquid nitrogen washing tail gas, and achieve the effect of flexible use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Example 1 Liquid nitrogen tail washing to produce hydrogen for hydrogenation

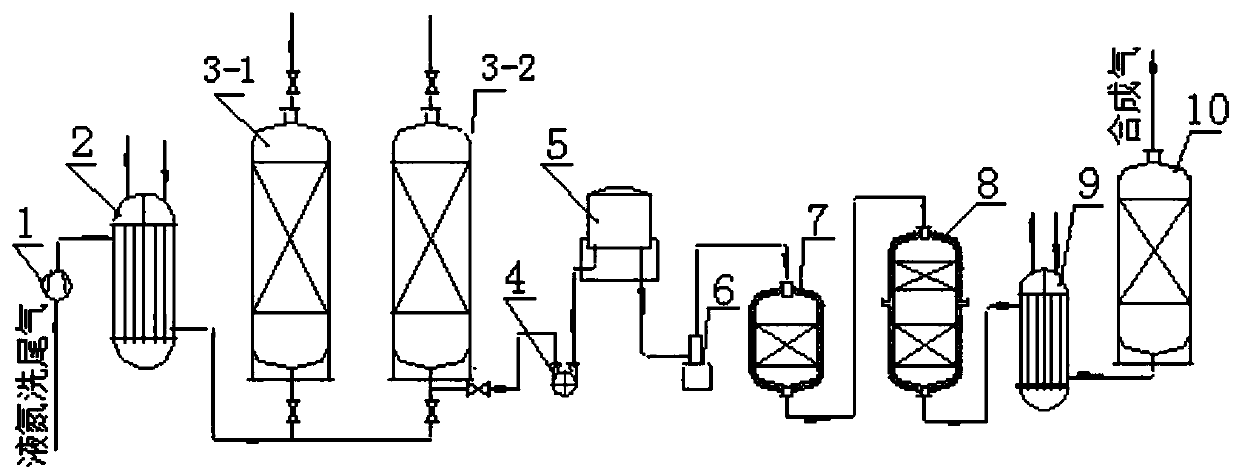

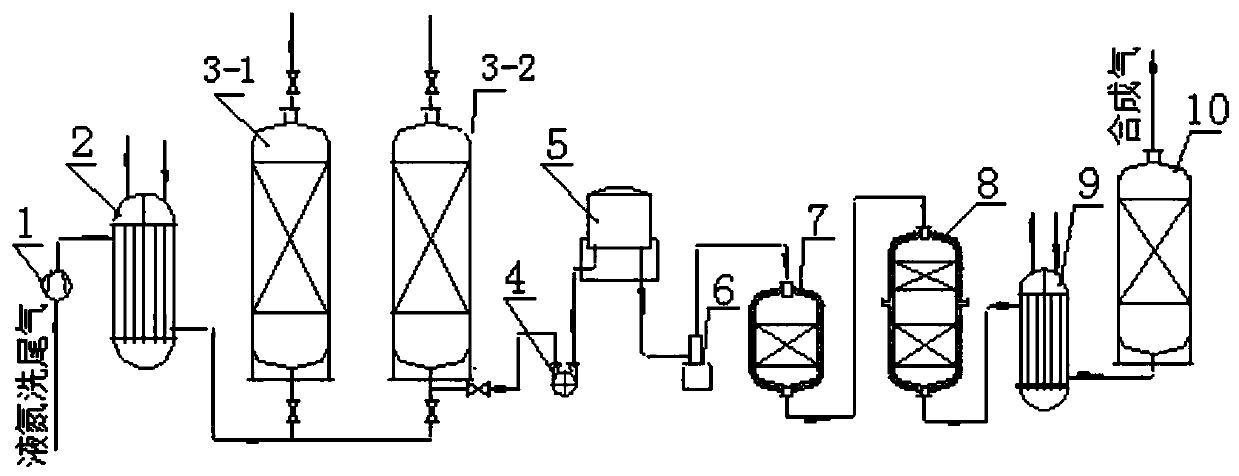

[0061] figure 1 It is the device diagram for resource utilization of liquid nitrogen washing tail gas in Example 1. The number of CO adsorbers is 2. In the figure, 1 is a turbine blower, 2 is a water cooler, 3-1 is the first CO adsorber, 3- 2 is the second CO adsorber, 4 is the vacuum pump, 5 is the gas cabinet, 6 is the compressor, 7 is the high temperature shift furnace, 8 is the medium and low temperature shift furnace, 9 is the water cooler, and 10 is the decarbonization adsorber.

[0062] Liquid nitrogen scrubbing tail gas treatment capacity: 28000~30000m 3 / h, liquid nitrogen wash tail gas components (volume fraction): CO 10%, H 2 1.7%, CH 4 0.3%, N 2 88%. The liquid nitrogen wash tail gas enters the turbine blower (1) from the main pipe at 0.1MPa (gauge pressure) to increase the pressure to 0.3MPa, and then enters the water cooler (2) outside the tube. At the bottom of the CO a...

Embodiment 2

[0065] Example 2 The tail gas was washed with liquid nitrogen to produce synthetic ammonia synthesis gas, and the device was the same as that of Example 1.

[0066] Liquid nitrogen scrubbing tail gas treatment capacity: 28000~30000m 3 / h, liquid nitrogen wash tail gas component (volume fraction): CO 6%, H 2 1.2%, CH 4 0.8%, N 2 88%. The liquid nitrogen wash tail gas enters the turbine blower (1) from the main pipe at 0.1MPa (gauge pressure) to increase the pressure to 0.3MPa, and then enters the water cooler (2) outside the tube. At the bottom of the CO adsorber (3-1), carbon monoxide is adsorbed and retained, and the unadsorbed nitrogen and other components are discharged from the top of the first CO adsorber (3); two carbon monoxide adsorbers are used interchangeably, and the saturated first CO The adsorber (3-1) is regenerated. At this time, the adsorption of carbon monoxide is carried out in the second CO adsorber (3-2), and it is extracted from the bottom of the sec...

Embodiment 3

[0067] Example 3 Wash tail gas with liquid nitrogen to produce methanol synthesis gas, the device is the same as that in Example 1.

[0068] Liquid nitrogen scrubbing tail gas treatment capacity: 20000~25000m 3 / h, liquid nitrogen wash tail gas component (volume fraction): CO 6%, H 2 2.1%, CH 4 0.9%, N 2 88%. The liquid nitrogen wash tail gas enters the turbine blower (1) from the main pipe at 0.1MPa (gauge pressure) to increase the pressure to 0.35MPa, and enters the water cooler (2) outside the pipe. At the bottom of the CO adsorber (3-1), carbon monoxide is adsorbed and retained, and the unadsorbed nitrogen and other components are discharged from the top of the first CO adsorber (3); two carbon monoxide adsorbers are used interchangeably, and the saturated first CO The adsorber (3-1) is regenerated. At this time, the adsorption of carbon monoxide is carried out in the second CO adsorber (3-2), and it is extracted from the bottom of the second CO adsorber (3-2) with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com