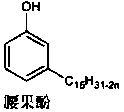

Cardanol/fluorocarbon resin/zinc powder composite marine salt mist-resistant paint and preparation method thereof

A fluorocarbon resin and cardanol technology, which is applied in the field of cardanol/fluorocarbon resin/zinc powder composite marine salt spray resistant paint and its preparation, can solve the problem that cardanol/fluorocarbon resin-based composite materials have not been reported, cardanol The base coating resin has problems such as insufficient salt spray corrosion resistance, and achieves excellent physical and mechanical properties, improved salt spray resistance, and improved photoaging effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

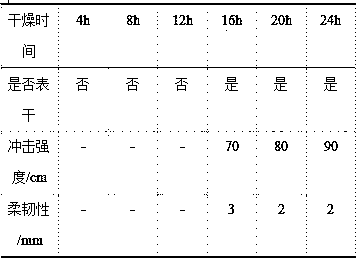

[0025] Cardanol, fluorocarbon resin, and zinc powder are mixed in a mass ratio of 3:4:3, and then add preservative sodium benzoate accounting for 1 wt% of the mixture of the three, and mechanically stir and mix at room temperature for 10 minutes to obtain cardanol / fluorocarbon resin / Zinc powder composite marine anti-corrosion paint.

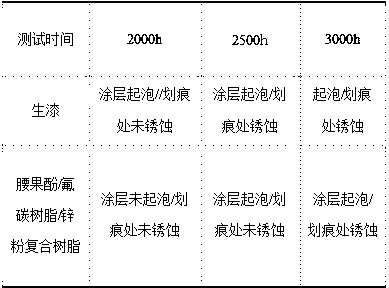

[0026] When the marine salt spray resistant paint is used, 10wt% of the total mass of curing agent hexamethylene diisocyanate trimer needs to be added, and it can be applied after curing for 15 minutes. Coating can be applied after mixing with curing agent and curing for 15 minutes. The coating can be cured at room temperature to form a film within 24 hours. The impact resistance of the coating is increased to 100cm, the flexibility is increased to 2mm, the salt spray resistance reaches 3000h, the anti-light aging performance reaches 3000h, and the discoloration and loss of light are ≤ 2 grades.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com