BMC (Bulk molding compound) material for high-speed rails and production method thereof

A high-speed iron and pigment technology, applied in the field of high-speed iron materials, can solve the problems of reduced tensile strength and elongation at break, reduced impact strength, wrapping, etc., to improve stability and fatigue resistance, increase service life, and improve smoothness. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

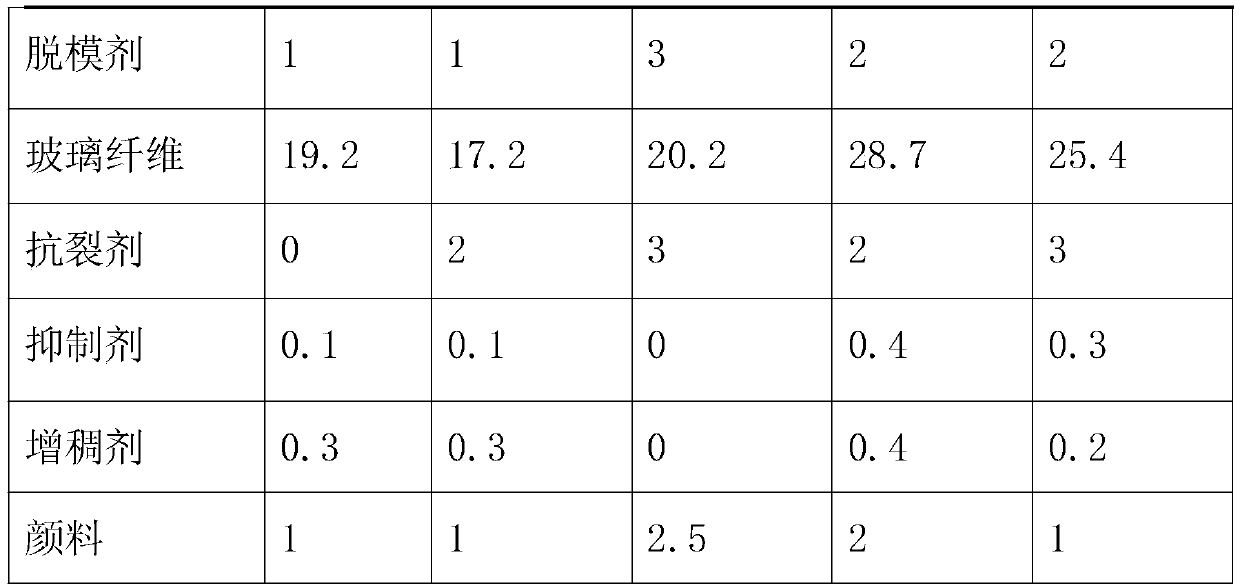

[0030] BMC materials for high-speed rail include unsaturated resin, low-shrinkage resin, aluminum hydroxide, curing agent, mold release agent, glass fiber, anti-cracking agent, inhibitor, thickener, and pigment as shown in the following table. .

[0031] A method for making a BMC material for high-speed rail, comprising the steps of:

[0032] Step 1, adding the above-mentioned curing agent, pigment, release agent, inhibitor and part of the resin into the dispersion tank, dispersing and stirring for 20 minutes to obtain a uniformly stirred liquid; the mass of the part of the resin accounts for 60-90% of the total resin;

[0033] Step 2, adding the anti-cracking agent and aluminum hydroxide into the kneader, stirring for 10 minutes, to obtain a uniformly stirred powder;

[0034] Step 3, adding the liquid in step 1 to the powder in step 2 to obtain a uniformly mixed paste;

[0035] Step 4: Add the thickener to the paste in Step 3, put it in a kneader and stir for 5 minutes to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com