High-temperature-resisting and easy-to-process semi-aromatic polyamide and preparation method thereof

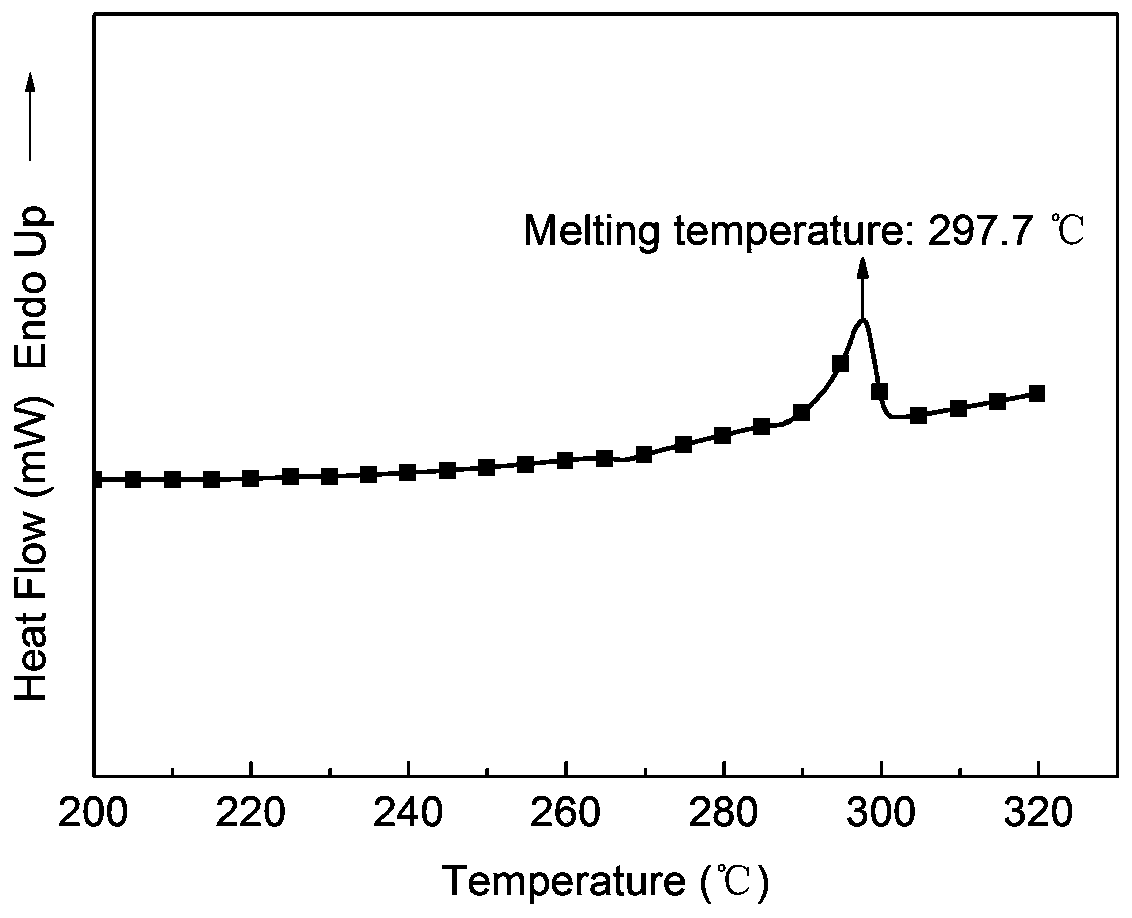

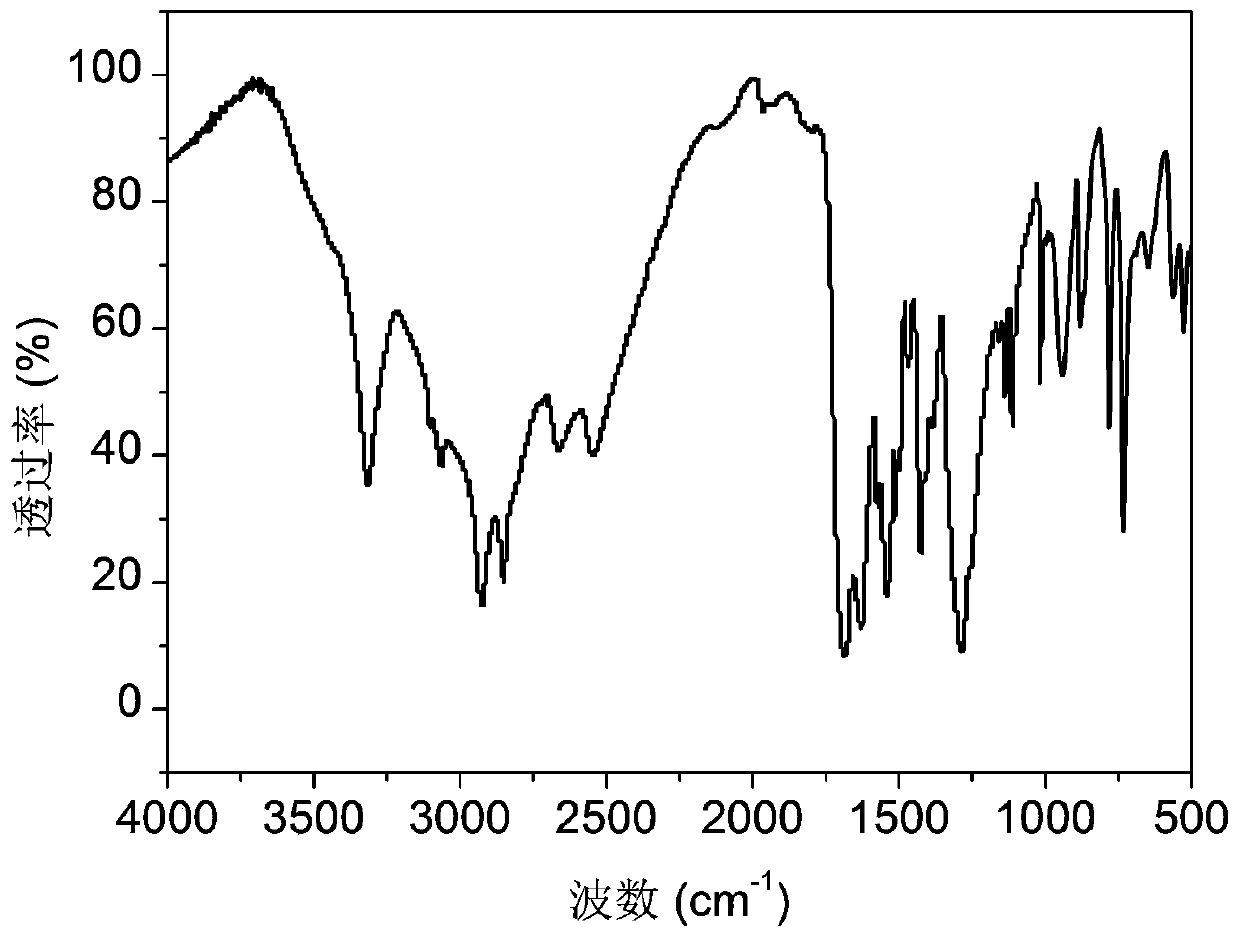

A semi-aromatic polyamide, an easy-to-process technology, applied in the field of high-temperature-resistant and easy-to-process semi-aromatic polyamide and its preparation, can solve the problems of high melting point, poor dimensional stability, poor performance retention, and poor toughness, and achieve good toughness , Improve dimensional stability and performance retention, and lower the melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A preparation method of a 10T type high temperature resistant and easy-to-process semi-aromatic polyamide (abbreviated as 10T / OADP):

[0053] Step 1: Preparation of dimer acid salt, weigh unhydrogenated dimer acid 2824.50g (about 5mol), pentamethylenediamine 1132.21g (about 5.05mol) and 4000g deionized water, mix well and pour it into 20L stainless steel reactor. Turn on the stirring device and set the rotation speed to 60r / min, and pass in nitrogen to replace the air in the reaction kettle. The temperature was raised to 80° C. for a salt-forming reaction, and the reaction was stopped after 3 hours of normal pressure reaction. The reactant was separated by suction filtration, the filter cake was washed with absolute ethanol and deionized water, and then the product was dried under vacuum at 80° C. for 12 hours to obtain a white dimer salt powder, which was ready for use.

[0054] Step 2: precondensation reaction, 1231.69g (about 7.41mol) of terephthalic acid, 1281.93g...

Embodiment 2

[0060] The preparation method of a kind of 10T high-temperature-resistant and easy-processing semi-aromatic polyamide (abbreviated as 10T / OADP) is as follows:

[0061] Step 1: the preparation of the dimer salt is the same as in Example 1. This example directly uses the dimer salt prepared in Example 1.

[0062] Step 2: precondensation reaction: 1231.69g (about 7.41mol) of terephthalic acid, 1281.93g (about 7.41mol) of decyl diamine, 267.94g of dimer salt (about 2.5% of the total molar ratio of diacid / diamine) %), sodium phosphite 8.00g, benzoic acid 45.25g and 1200g deionized water drop into the stainless steel reactor, and pass into the air in the nitrogen replacement reactor three times. Set the speed at 250r / min, raise the temperature to 160°C, and the pressure to 0.6MPa, and react for 1.5 hours; continue to raise the temperature to 235°C, keep the pressure at 2.5MPa, and react for 5 hours to ensure that terephthalic acid, decanediamine and The full reaction of the dimer ...

Embodiment 3

[0065] The preparation method of 9T high-temperature-resistant and easy-processing semi-aromatic polyamide (referred to as 9T / OADP) is as follows:

[0066] Step 1: Preparation of dimer salt: same as in Example 1. The diamine uses nonanediamine, and dimer acid is used to make dimer salt.

[0067] Step 2: precondensation reaction, 1231.69g (about 7.41mol) of terephthalic acid, 1178.19g (about 7.41mol) of nonanediamine, 428.70g of dimer salt (about 4% of the total molar ratio of diacid / diamine) %), sodium phosphite 8.00g, benzoic acid 45.25g and 1200g deionized water drop in the stainless steel reactor, airtight reactor, vacuumize, then pass into nitrogen, then vacuumize the air in the nitrogen replacement reactor three times. Set the speed at 200r / min, raise the temperature to 150°C, and the pressure to 0.5MPa, and react for 2 hours; continue to raise the temperature to 230°C, keep the pressure at 2.5MPa, and react for 4 hours to ensure that terephthalic acid, nonanediamine and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com