Stylized transfer device based on bionic structure

A bionic and transfer printing technology, which is applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc., can solve problems such as thermal expansion, uncontrollable speed, and high failure rate, and achieve low operating skill requirements, efficient pick-up and put down, and realization transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Exemplary embodiments of the present invention are described below with reference to the accompanying drawings. It should be understood that these specific descriptions are only used to teach those skilled in the art how to implement the present invention, but are not intended to exhaust all possible ways of the present invention, nor are they intended to limit the scope of the present invention.

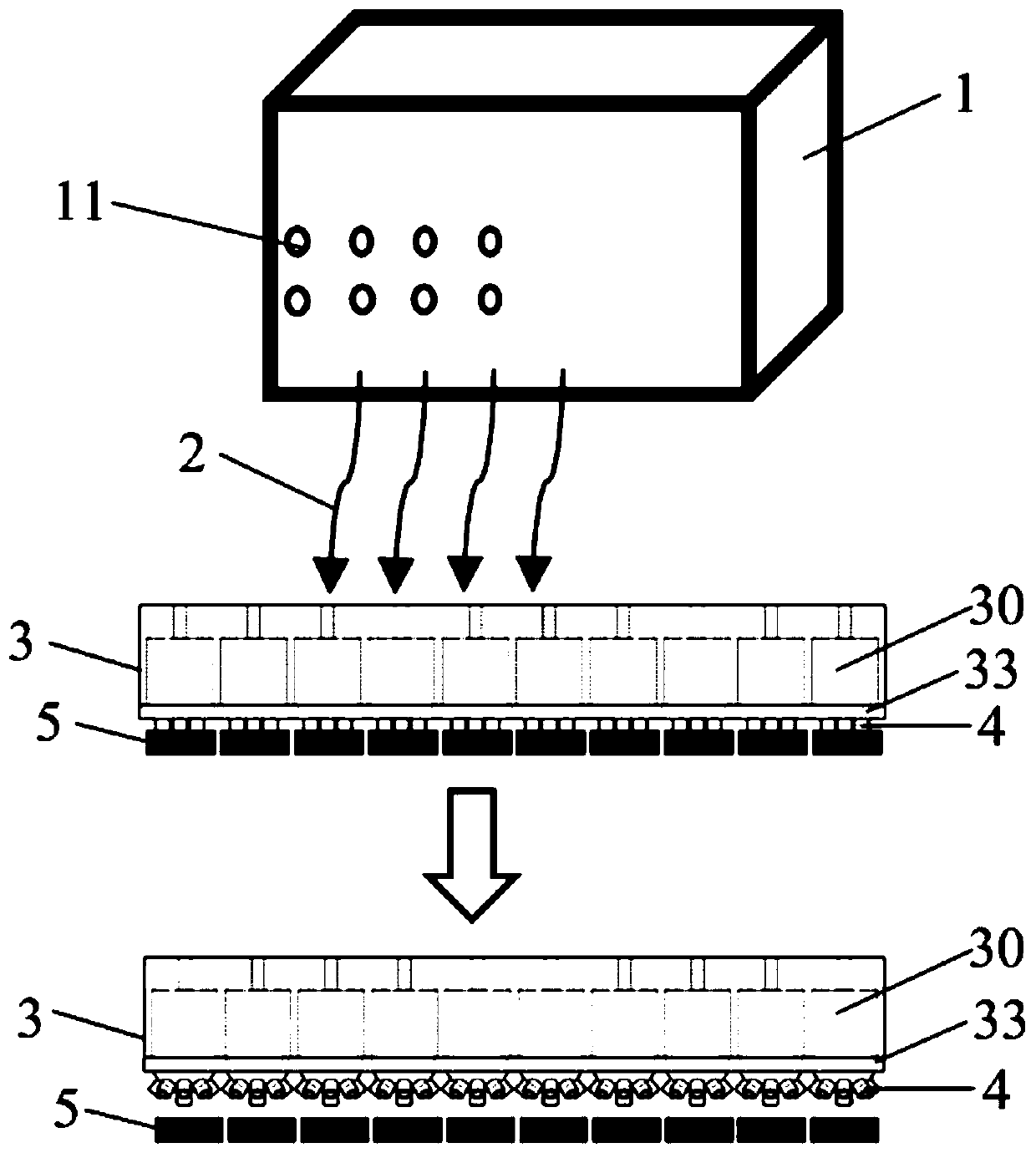

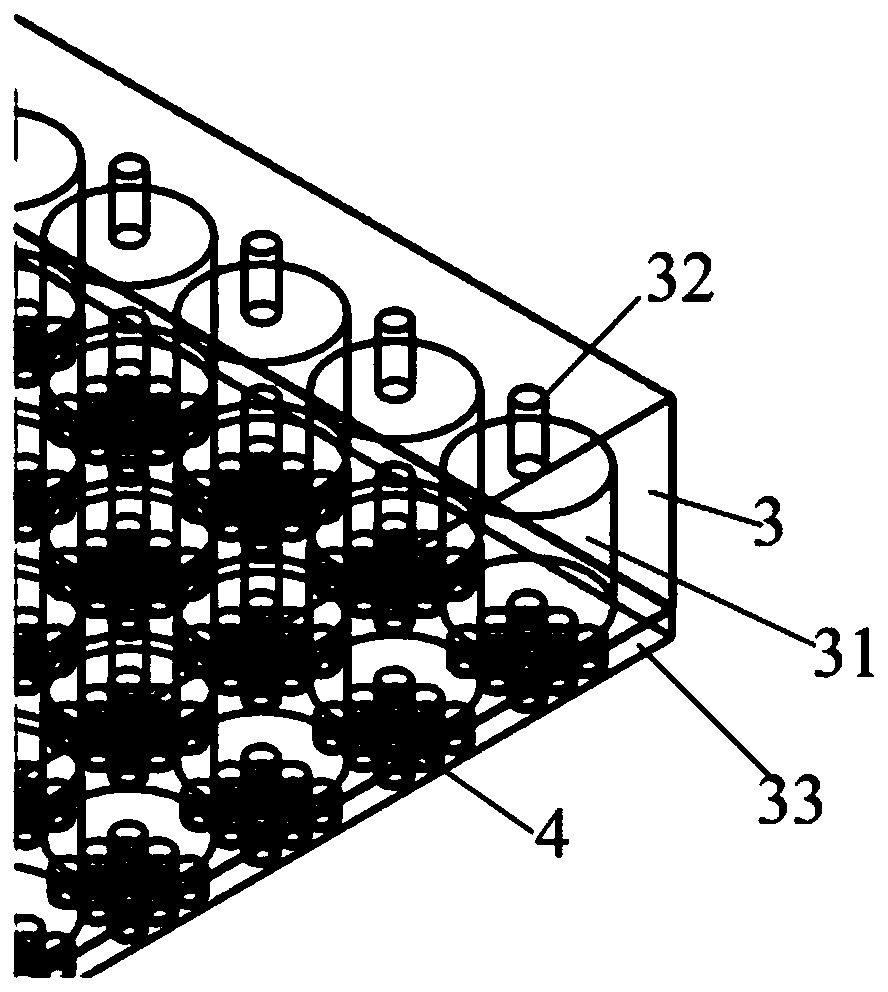

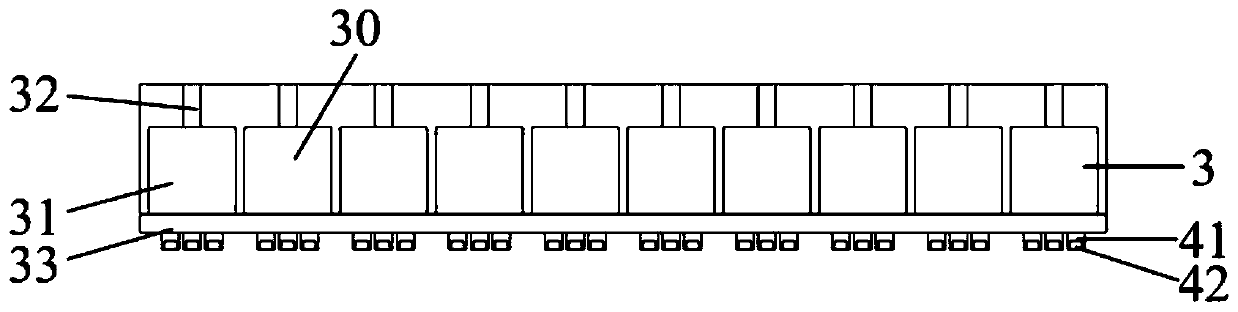

[0041] Such as Figure 1 to Figure 10 As shown, the present disclosure provides a stylized transfer printing device based on a bionic structure, which has an electronic control module 1, an air pipe 2, a stamp base 3 and a suction cup assembly 4, and the suction cup assembly 4 is used to attract the object 5 to be transferred .

[0042] The stamp base 3 is formed with an air chamber 30 , the air tube 2 is connected to the air chamber 30 , a part of the air chamber wall of the air chamber 30 is formed by a film 33 , and the suction cup assembly 4 is connected to the film 33 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com