A dpf regeneration system and control method for optimizing thermal management

A regeneration system, DPF technology, applied in the direction of electronic control of exhaust treatment device, diagnosis device of exhaust treatment device, exhaust gas treatment, etc., can solve problems such as low regeneration efficiency, eliminate energy loss, increase residence time, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

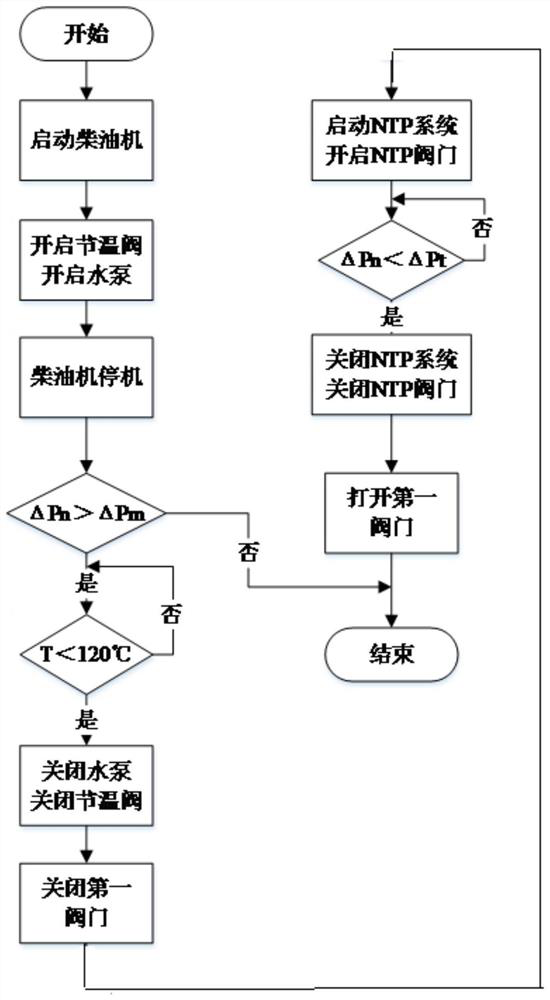

[0033]The present invention is made in conjunction with the accompanying drawings and specific examples, but the scope of the invention is not limited thereto.

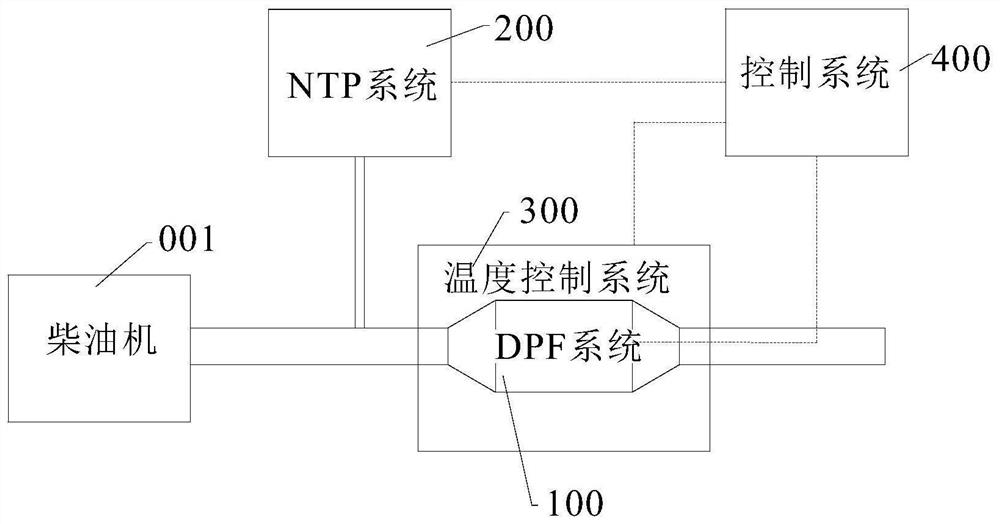

[0034]Joinfigure 1 As shown, the optimized thermal management of the present invention includes a DPF system, an NTP system, a temperature control system, and a control system. The low-temperature plasma system 200 is mounted upstream of the DPF system 100, and provides an active gas for the DPF system 100; the temperature control system 400 provides a target operating temperature of the particulate matter.

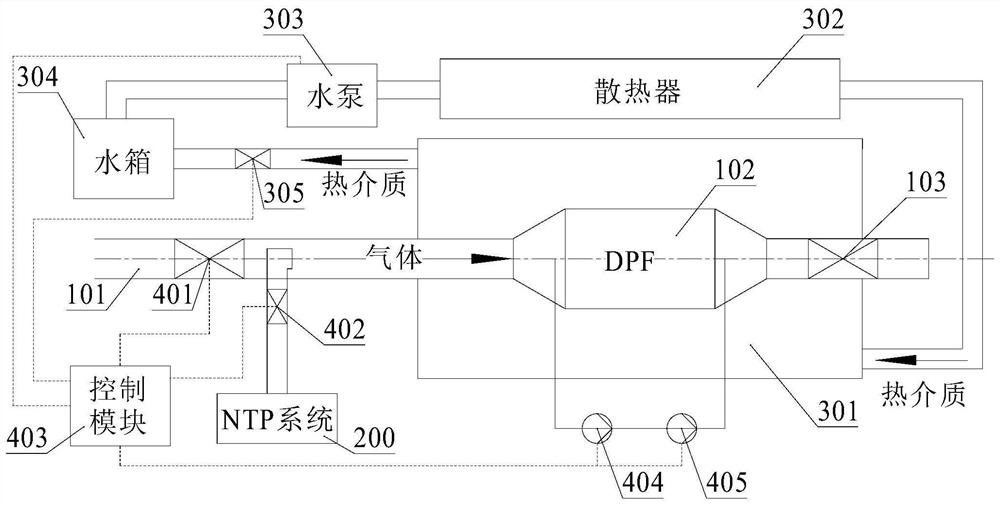

[0035]Joinfigure 2 As shown, the DPF system includes a main exhaust pipe 101, a DPF 102, and a pressure valve 103. The temperature control system includes an incubator 301, a heat sink 302, a water pump 303, a water tank 304, and a thermostat valve 305. The control system includes a first valve 401, an NTP valve 402, a control module 403, a differential pressure sensor 404, and a temperature sensor 405. The exhaust gas in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com