Adhesive tape for batteries

A tape and battery technology, applied in the direction of secondary batteries, secondary battery manufacturing, non-aqueous electrolyte storage batteries, etc., can solve the problems of battery productivity reduction, poor insertion, etc., and achieve the effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

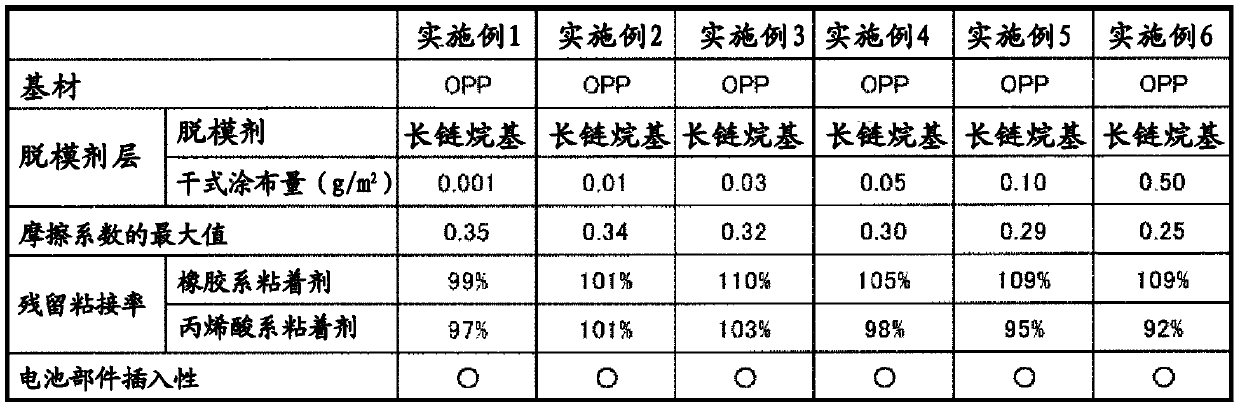

Embodiment 1~6

[0059] The static friction coefficient and dynamic friction coefficient of a biaxially stretched polypropylene film with a thickness of 20 μm [Toray Co., Ltd., TORAYFAN (registered trademark)] (OPP film, before application of release agent) used as a substrate were measured by the following method As a result, the maximum value is 0.43.

[0060] (Determination of the maximum value of static friction coefficient and dynamic friction coefficient)

[0061] Measure the maximum value of static friction coefficient and dynamic friction coefficient according to JIS K7125. Specifically, using a friction coefficient measuring machine (manufactured by Toyo Seiki Seisakusho Co., Ltd.), the static friction coefficient and the coefficient of static friction were measured under the conditions of a weight of the sliding sheet of 200 g, a contact area of 6.3 m×6.3 m, and a stretching speed of 100 mm / min. For the coefficient of dynamic friction, set the highest value to the "maximum value".

[00...

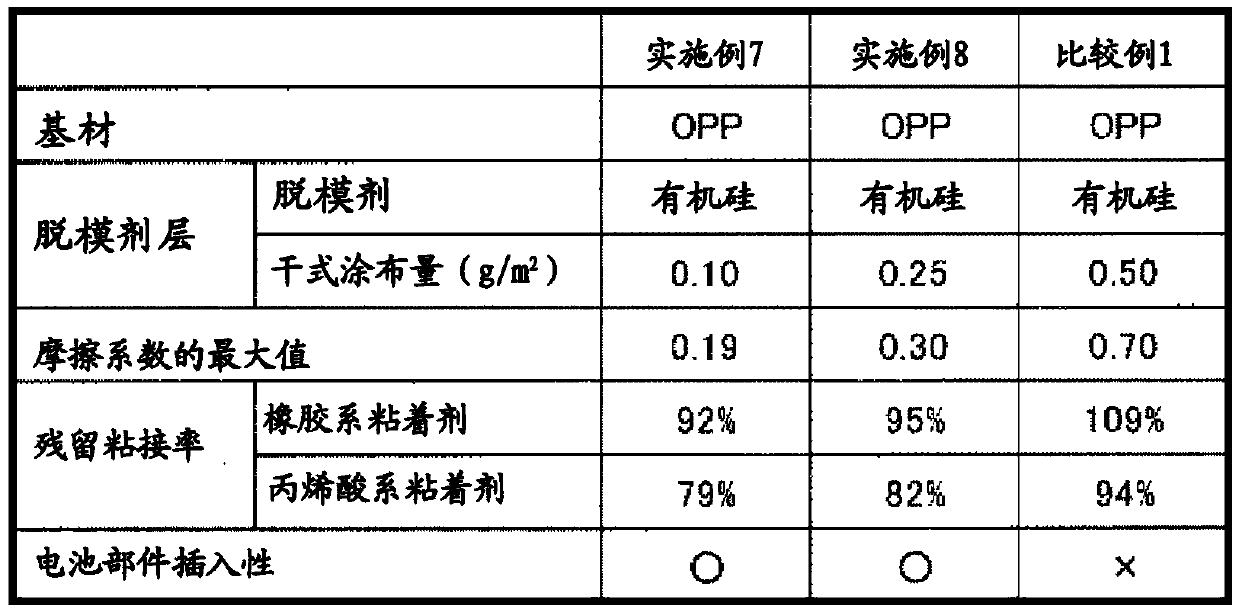

Embodiment 7~8 and comparative example 1

[0066] As the mold release agent, a silicone mold release agent (manufactured by Shin-Etsu Chemical Co., Ltd., KS-847T) was used, and the dry coating amount was applied to the amount described in Table 2. Otherwise, the same as in Examples 1 to 6 In the same manner, a rubber-based adhesive tape and an acrylic adhesive tape were produced.

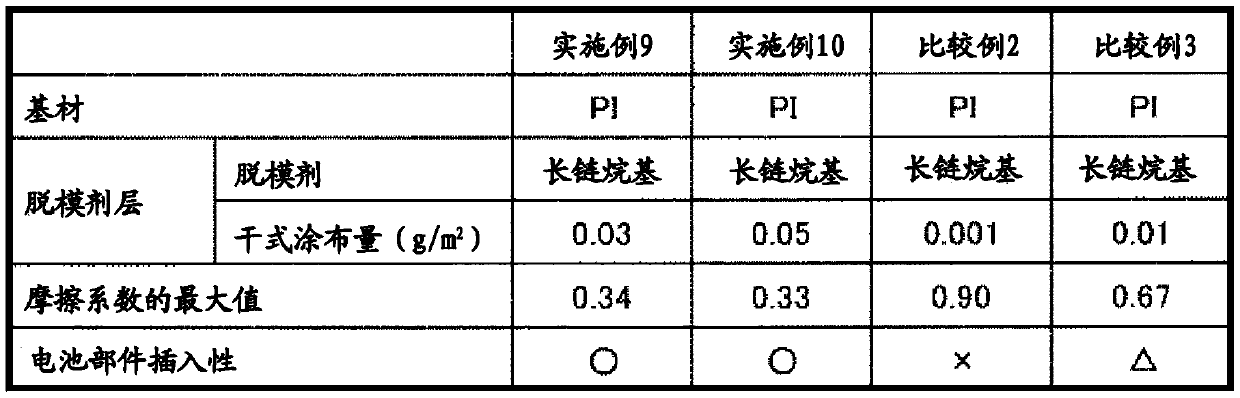

Embodiment 9~10 and comparative example 2~3

[0068] As the base material, a polyimide film with a thickness of 25μm [manufactured by Toray-DuPont Co., Ltd., KAPTON (registered trademark) 100H] (PI film, maximum friction coefficient = 1.45) is used, and the dry coating amount is Except for applying the long-chain alkyl-based release agent as the release agent in the amount described in Table 3, the same procedure as in Examples 1 to 6 was carried out to produce a rubber-based adhesive tape and an acrylic adhesive tape.

[0069]

[0070] As the mold release agent, a silicone mold release agent (manufactured by Shin-Etsu Chemical Co., Ltd., KS-847T) was used, and the dry coating amount was applied to the amount described in Table 4. Other than that, the same as in Examples 9 to 10 In the same manner, a rubber adhesive tape and an acrylic adhesive tape were produced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com